82E-5 – 98E-5 SERIES 8-7

8. TURBOCHARGER

8.3 Periodic Inspection Procedure

8.3.1 Periodic inspection intervals

Periodically inspect the turbocharger for the overall conditions and fouling.

The inspection interval varies with the operating conditions, but refer to the table below for the guideline for each

application.

8.3.2 Inspection procedure

(1) Rotor rotation inspection

Inspect the rotor rotation by listening to any abnormal sound generation during rotation.

For inspection with a sound detecting bar, bring the tip end of the bar into strong contact with the turbo-

charger case and raise the engine speed gradually.

If any high pitch sound is generated at intervals of 2 to 3 seconds, the rotation is abnormal. Since the bear-

ing or rotor may be defective in this state, either replace or overhaul the turbocharger.

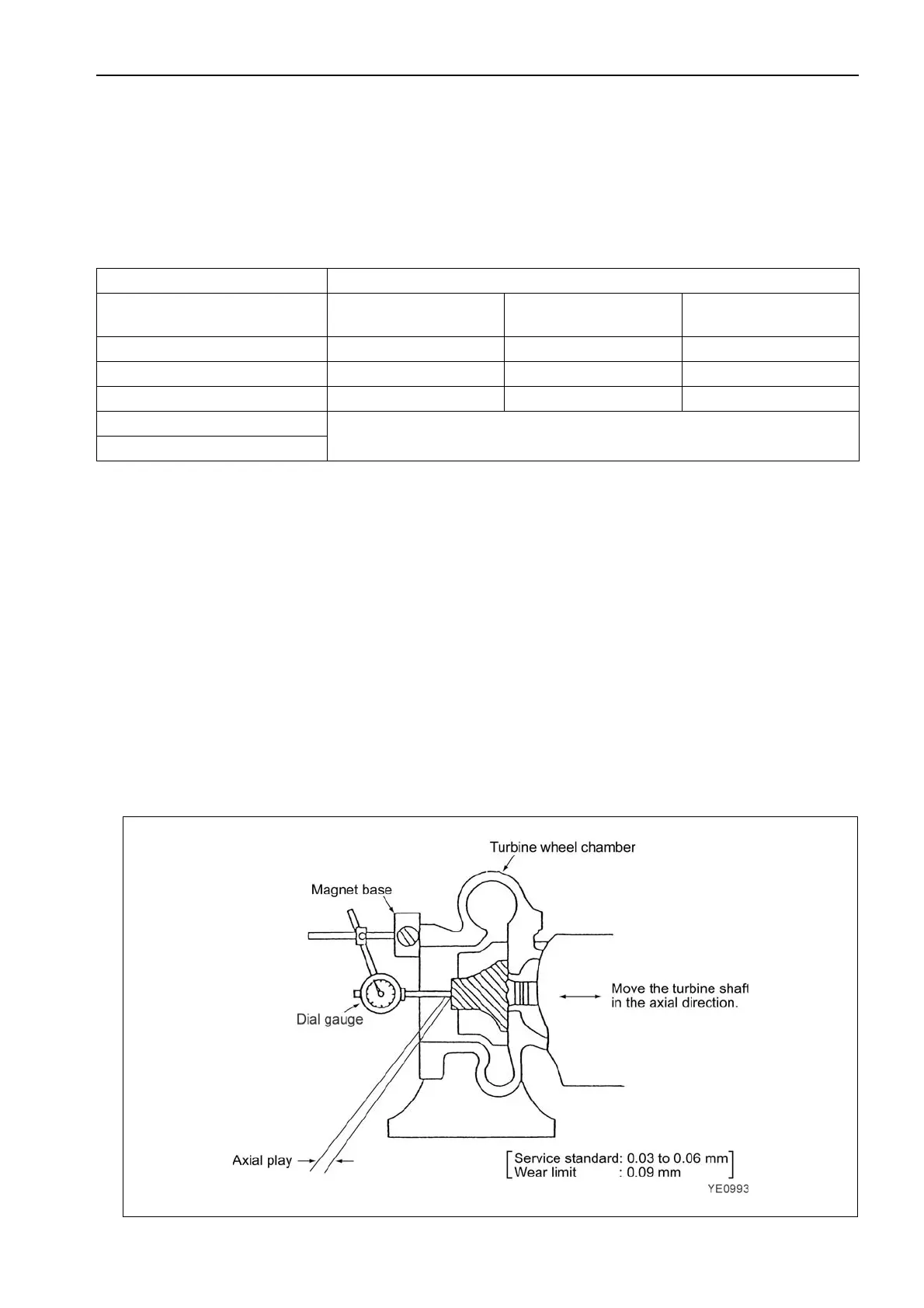

(2) Rotor play inspection

Remove the turbocharger from the engine and inspect the rotor play in the axial and radial directions

according to the procedure below.

After removing the turbocharger from the engine, always bind the oil inlet and outlet holes with adhesive

tape.

Rotor play in axial direction

Application Inspection interval

For construction machinery

Every 6 months

or 500hrs

Every 12 months

or 1,000hrs

Every 24 months

or 2,000hrs

Rotor rotation

Q

Rotor play Q

Overhaul and overall inspection Q

Oil filter cleaning and inspection

Based on operation manual

Engine oil replacement

Loading...

Loading...