4-30 82E-5 – 98E-5 SERIES

4. DISASSEMBLY, INSPECTION AND REASSEMBLY OF ENGINES

4.3.5 Parts inspection and measurement

(1) Camshaft

Mainly check the contact between the tappet and cam contact surface, bearing seizure and wear, and gear

damage.

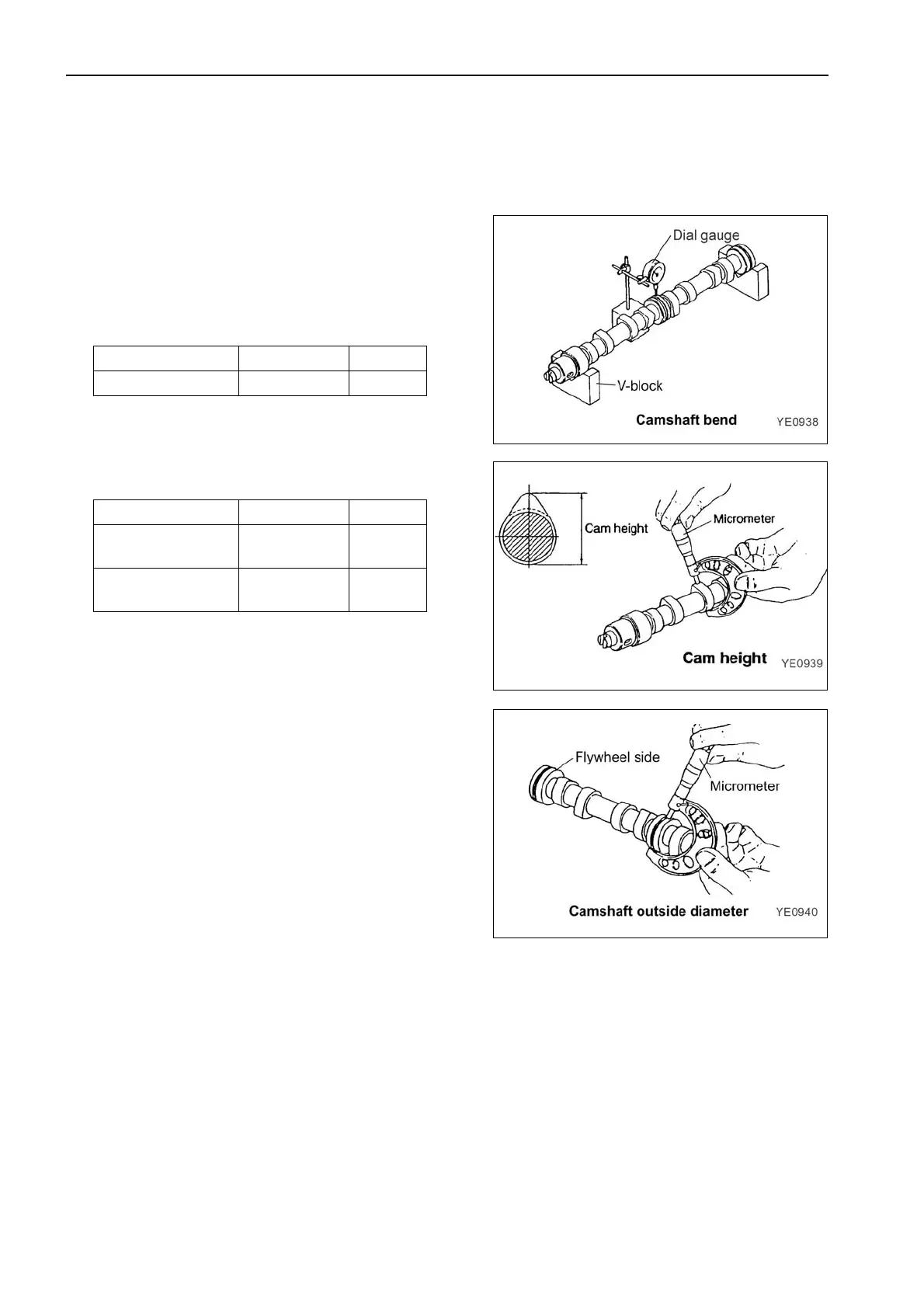

(a) Shaft bend measurement

Support the camshaft with V blocks. Rotate

the camshaft and measure the runout at the

center of the camshaft and at each journal

with a dial gauge. Half of the runout is the

bend.

mm

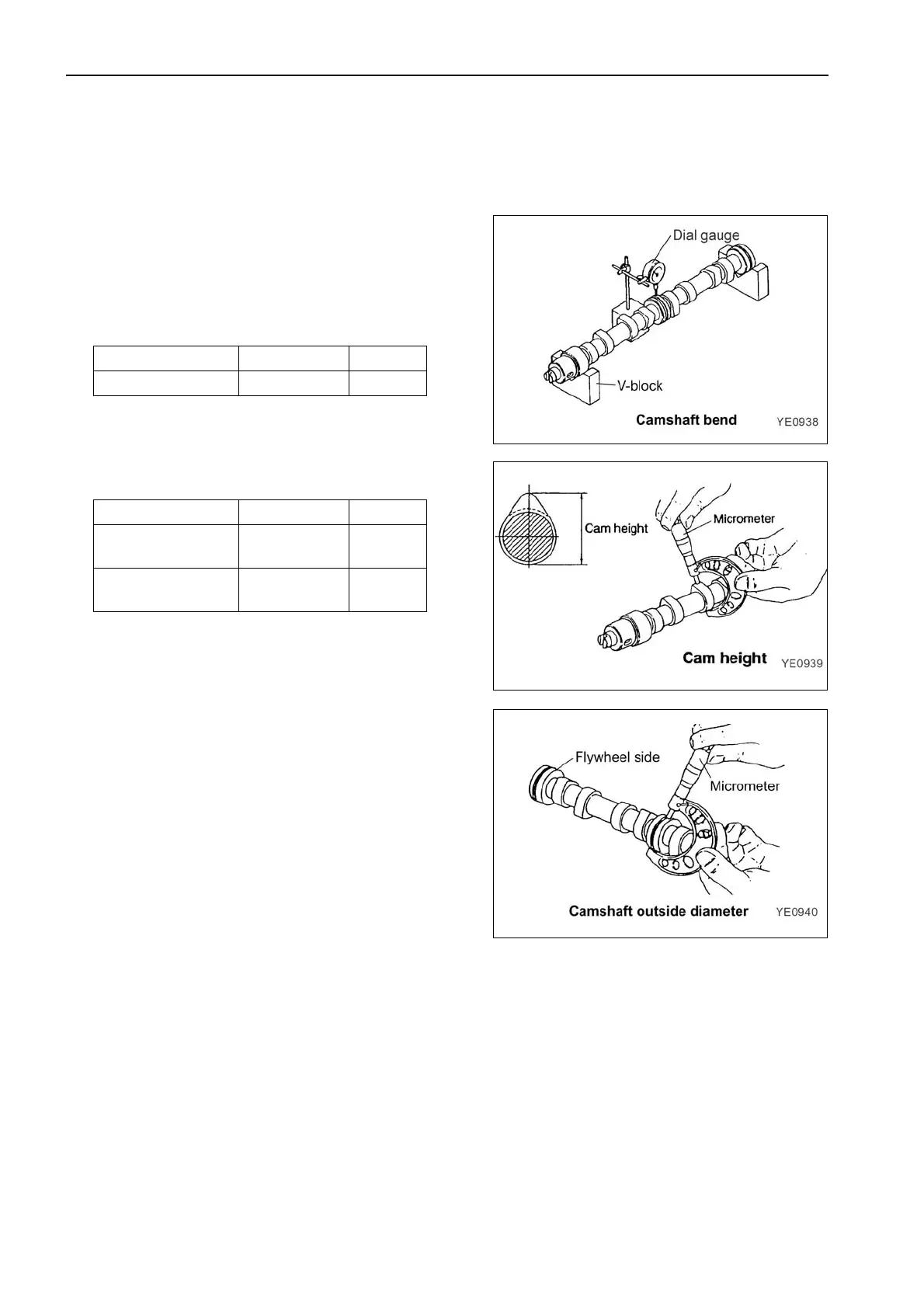

(b) Intake/exhaust cam height measurement

mm

(c) Camshaft and bearing hole measurement

Measure the camshaft outside diameter with

a micrometer. The oil clearance shall be

calculated by subtracting the measured

camshaft outside diameter from the inside

diameter of the camshaft bearing or bush-

ing. The camshaft bushing at gear case side

is measured with a cylinder gauge after

insertion to the cylinder.

Item Standard Limit

Bend 0 – 0.02 0.05

Model Standard Limit

3D82AE – 4D88E

38.600 –

38.800

38.350

4D94LE, (S)4D98E

43.400 –

43.600

43.150

Loading...

Loading...