8-12 82E-5 – 98E-5 SERIES

8. TURBOCHARGER

8.5 Washing and Inspection Procedure

8.5.1 Washing

(1) Inspection before washing

Visually inspect each part before washing to check trace of seizure, wear, foreign matter or carbon adhe-

sion.

Carefully inspect for identifying the cause of trouble especially when a fault has occurred.

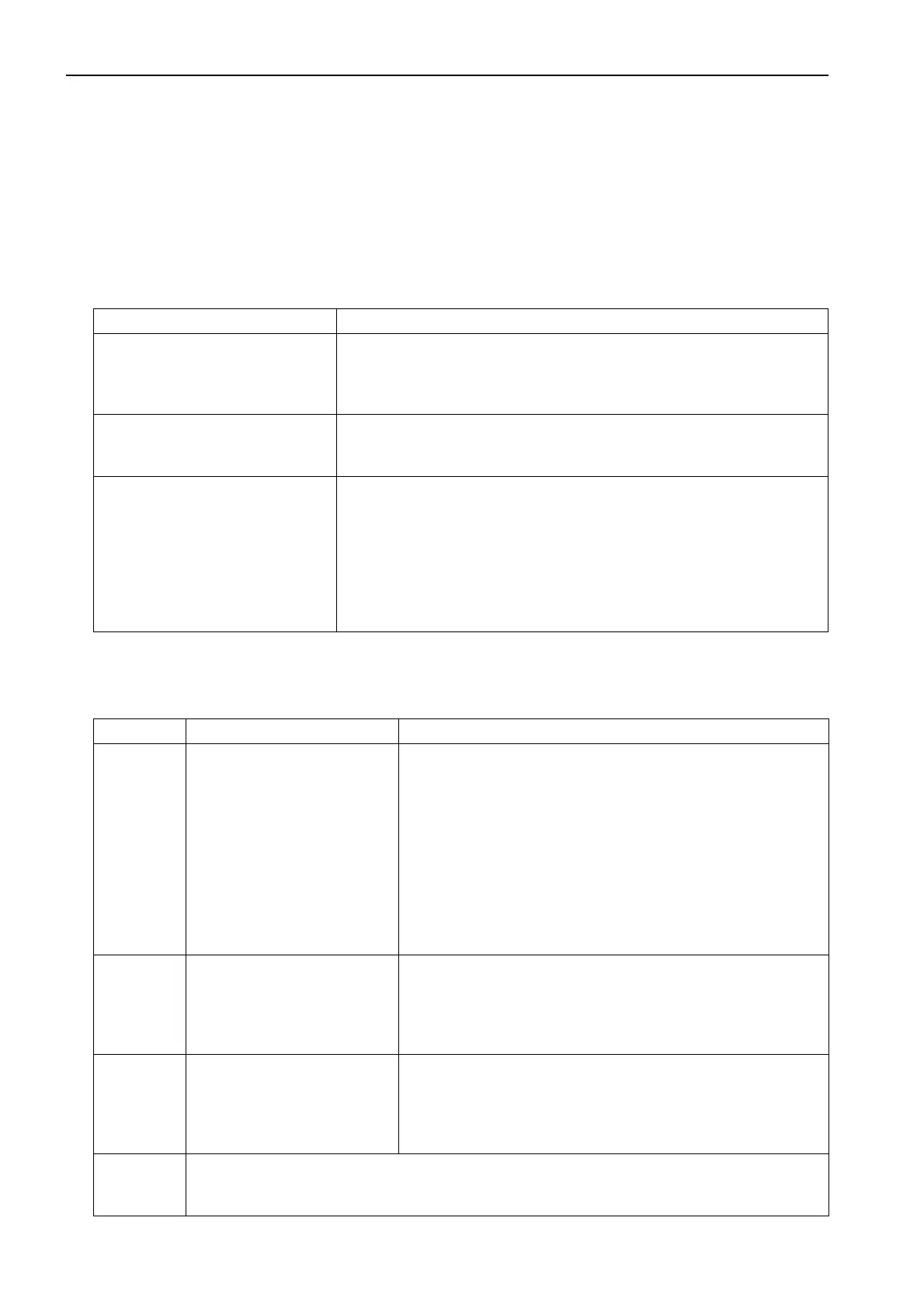

Major inspection items

(2) Washing procedure

Keep the following in mind when washing the parts.

Check point Checking position

Carbon adhesion state

1) Turbine shaft (1), turbine side seal ring and rear side of turbine

wheel

2) Heat insulating plate (20) mounting portion and inside of bearing

housing (15)

Lubrication status

(wear, seizure, discoloration, etc.)

1) Turbine shaft (1), journal portion and thrust bushing oil thrower (2)

2) Floating bearing (5) and thrust bearing (6)

3) Bearing housing (15) and inner wall of bearing fitting ring

Oil leak state

1) Inner wall of turbine housing (11)

2) Outer surface of bearing housing (11) and heat insulating plate (20)

mounting portion

3) Turbine shaft (1) turbine side seal ring portion and rear side of tur-

bine wheel

4) Inner wall of compressor housing (7)

5) Rear side of compressor impeller (18)

6) Surface and seal ring inserting portion of seal plate (4)

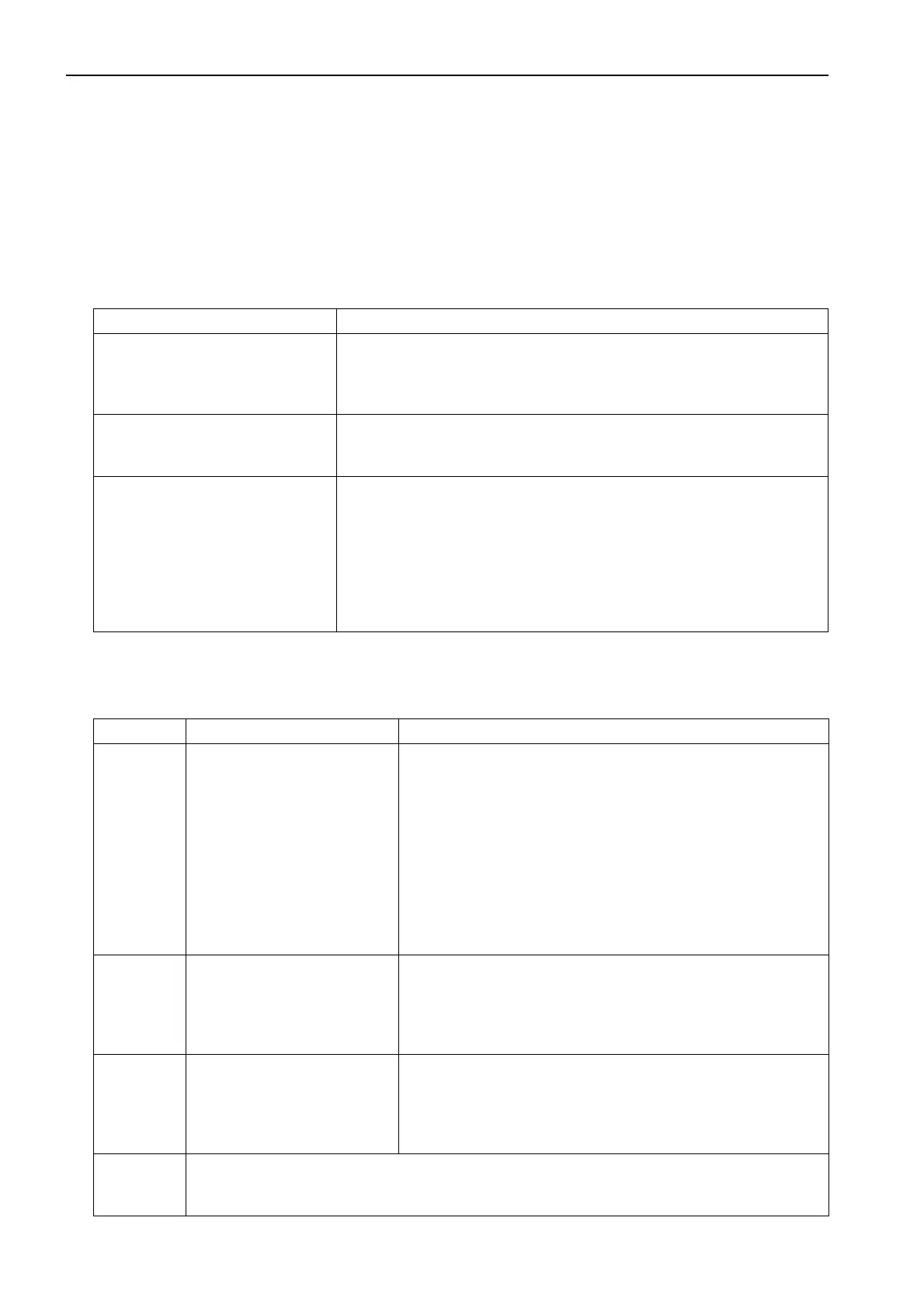

Part Tools and detergent Procedure

a) Turbine

shaft

• Tools

1) Bucket (500 x 500 mm)

2) Heat source:

Steam or gas burner

3) Brush

• Detergent

Standard carbon removing

agent

1) Boil the turbine in the washing bucket.

2) Do not strike the blade to remove the carbon.

3) Immerse in the detergent until the carbon and other

deposits are softened.

4) Use a plastic scraper or hand hair scrubber to remove the

softened deposits.

5) Protect the bearing surface and seal ring groove on the

turbine shaft so as not to be damaged.

6) Any deposit remaining on the turbine shaft due to

improper washing may cause unbalancing. Be sure to

remove thoroughly. Never use a wire brush.

b) Turbine

wheel

chamber

• Tools

Same as for turbine shaft

• Detergent

Same as for turbine shaft

1) Boil the turbine in the washing bucket.

2) Immerse in the detergent until the carbon and other

deposits are softened.

3) Use a plastic scraper or hard hair scrubber to remove the

softened deposits.

c) Blower

blade

and

chamber

• Tools

1) Bucket (500 x 500 mm)

2) Brush

• Detergent

1) Immerse in the washing bucket until the deposit is soft-

ened.

2) Use a plastic scraper or hard hair scrubber to remove the

softened deposits.

3) Never use a wire brush.

d) Others 1) Wash all other parts with diesel oil.

2) Clean the lubricating oil path by blowing with compressed air.

3) Be especially careful so as not to damage or corrode the parts.

Loading...

Loading...