2-26 82E-5 – 98E-5 SERIES

2. INSPECTION AND ADJUSTMENT

2.2.7 Inspection every 2000 hours or 2 years

Be sure to check the following points every 2,000 hours or two years operation, whichever comes first.

(1) Cooling water path flushing and maintenance

Rust and water scale will accumulate in the cooling system through many hours of operation. This lowers

the engine cooling effect. Oil coolers (attached to turbocharged engines and some of naturally aspirated

engines) quickly deteriorate the lube oil. The cleaning and maintenance of the following parts are neces-

sary in accordance with the cooling water replacement.

Cooling system parts: radiator, cooling water pump, thermostat, cylinder block, cylinder head, oil cooler.

(2) Fuel pipe and cooling water pipe inspection and maintenance

Regularly check the rubber hoses of the fuel system and cooling water system. If cracked or degraded,

replace them with new one. Replace the rubber hoses at least every 2 years even if 2,000 hours doesn't come.

(3) Intake/exhaust valve seat lapping

The adjustment is necessary to maintain proper contact of the valves and seats. Refer to 4.2.6 in Chapter 4.

(4) Fuel injection timing adjustment / Fuel injection pump inspection and adjustment

The fuel injection timing and the fuel injection pump are adjusted so that engine performance may become

the best condition. The fuel injection timing is adjusted by the following procedure.

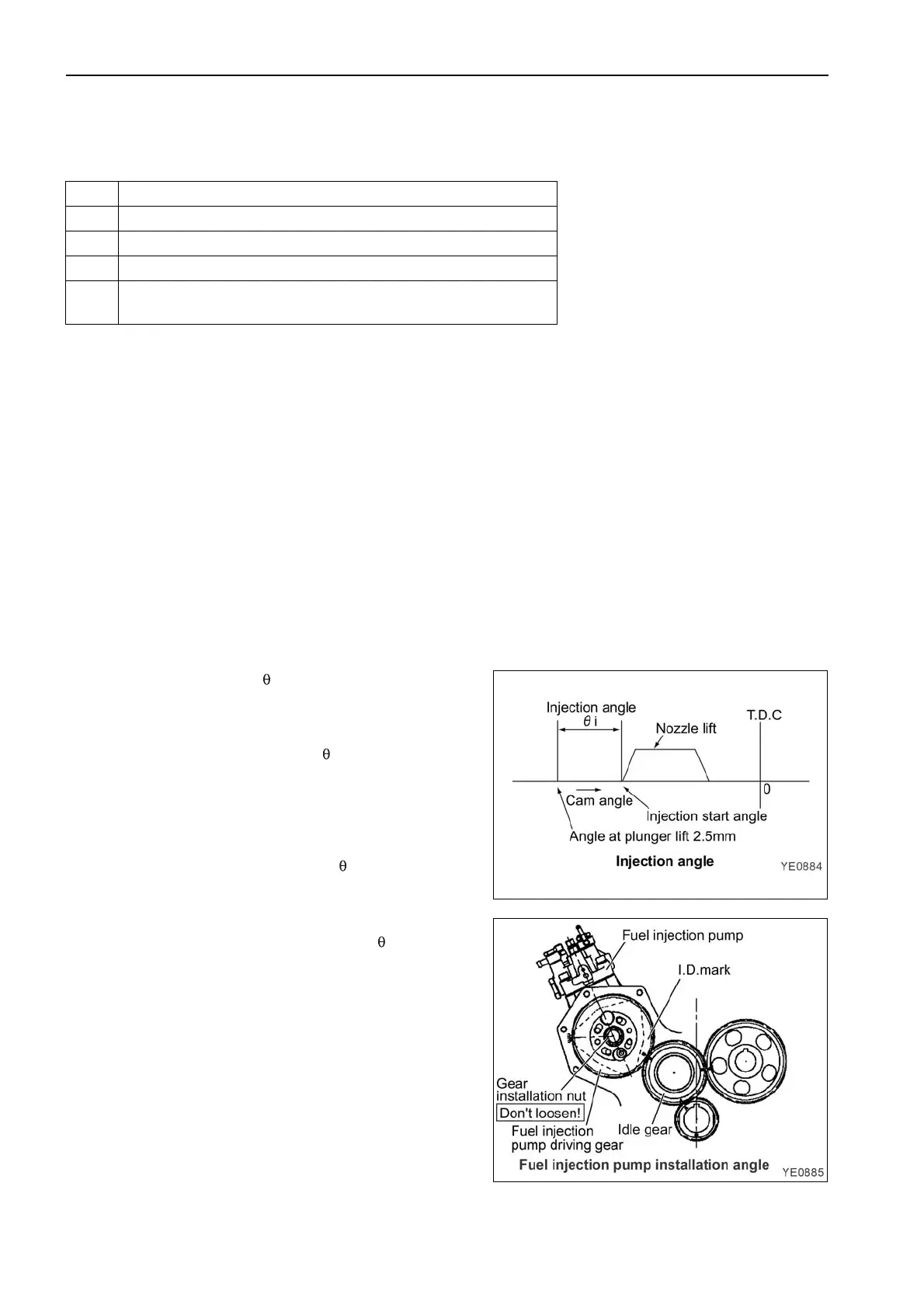

The fuel injection angle

i

(note) is adjusted for

the fuel injection timing adjustment, because the

adjusting method of fuel injection timing like an

inline fuel injection pump can't be applied.

Note) The fuel injection angle

i

(cam angle)

is the difference from the injection valve

opening angle while the fuel injection

pump being driven by a motor and the

angle at the plunger lift 2.5mm of the

fuel injection pump. And, as for the

actual fuel injection angle

i

, the mea-

sured value is recorded on the pump

body by each every fuel injection pump.

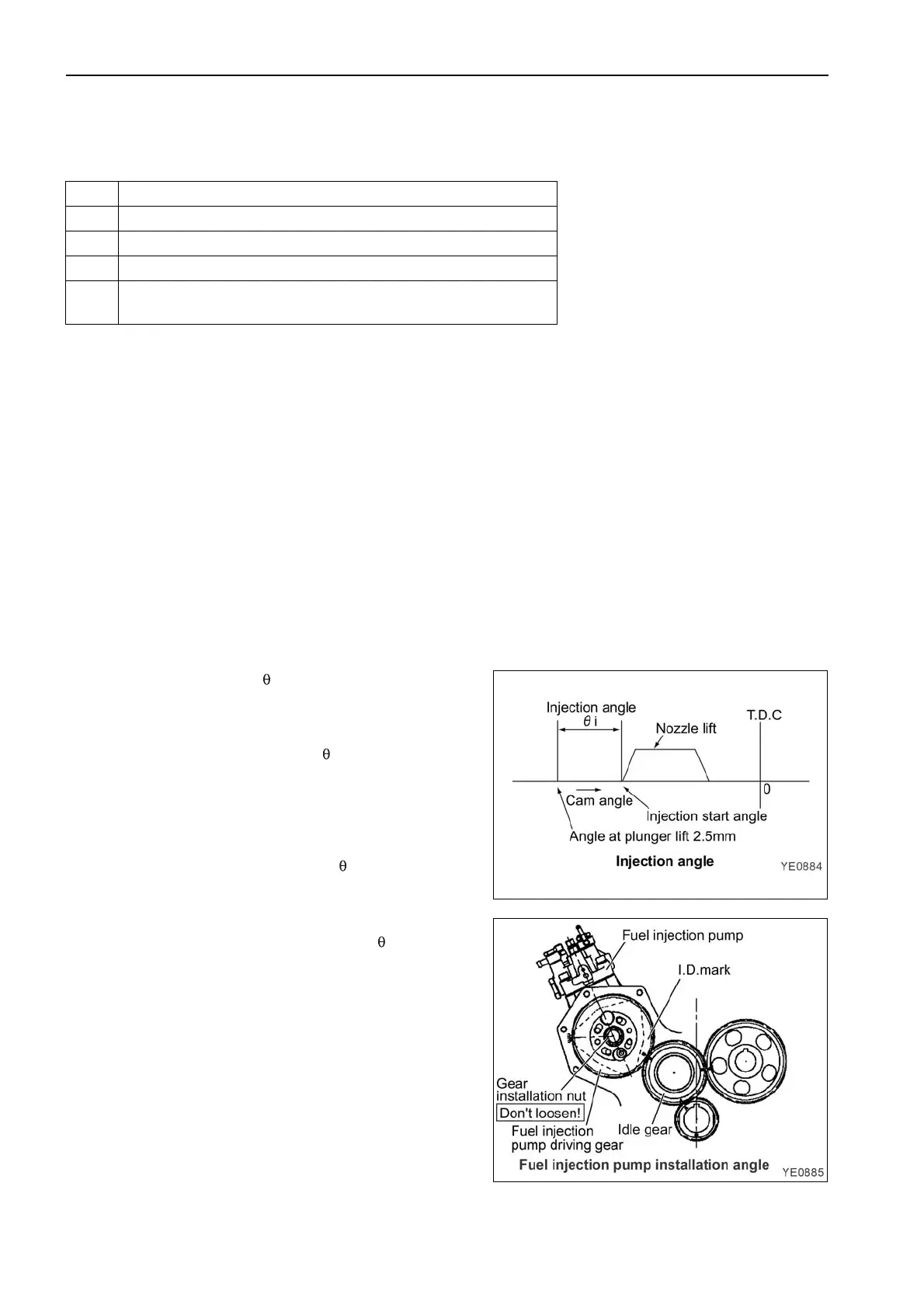

The adjustment of fuel injection angle

i

In case that a fuel injection pump cover, installed

with a gear case cover and the fuel injection

pump are removed, and reassembled, the pro-

cedure of fuel injection angle adjustment is as

follows. (As for the disassembly of a fuel injec-

tion pump, refer to 7.2.3 in chapter 7.)

[NOTICE]

Never loosen four flange bolts, which fasten a

pump flange and a fuel injection pump drive

gear at the time of the removal of the fuel injec-

tion pump. When it is loosened, the adjustment

of the fuel injection timing becomes very difficult.

No. Inspection Item

(1) Cooling water path flushing and maintenance

(2) Fuel pipe and cooling water pipe inspection and maintenance

(3) Intake/exhaust valve seat lapping

(4)

Fuel injection timing adjustment

Fuel injection pump inspection and adjustment

Loading...

Loading...