82E-5 – 98E-5 SERIES 8-13

8. TURBOCHARGER

8.5.2 Inspection procedure

(1) Compressor housing (7)

Inspect the compressor housing for any contact

trace with the compressor impeller, surface

defect, dent or crack at joint surface, and

replace it if defective.

(2) Turbine housing (11)

Inspect any trace of contact with the turbine

wheel, exfoliation due to degradation by oxida-

tion of the cast surface, thermal deformation or

crack.

Replace with a new one of defective.

(3) Compressor impeller (18)

Inspect any contact trace, chipping, corrosion or

deformation.

Replace with a new one if defective.

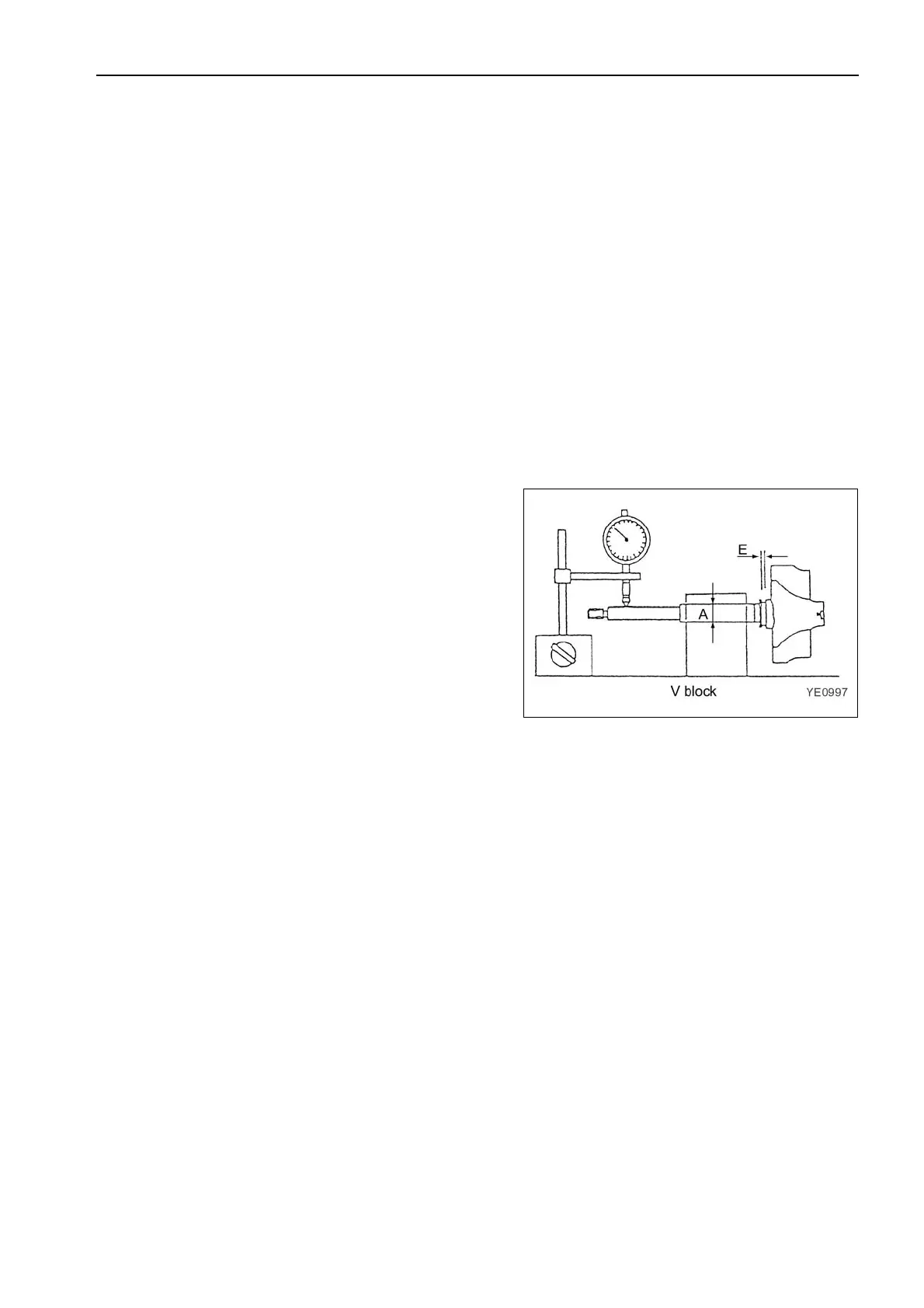

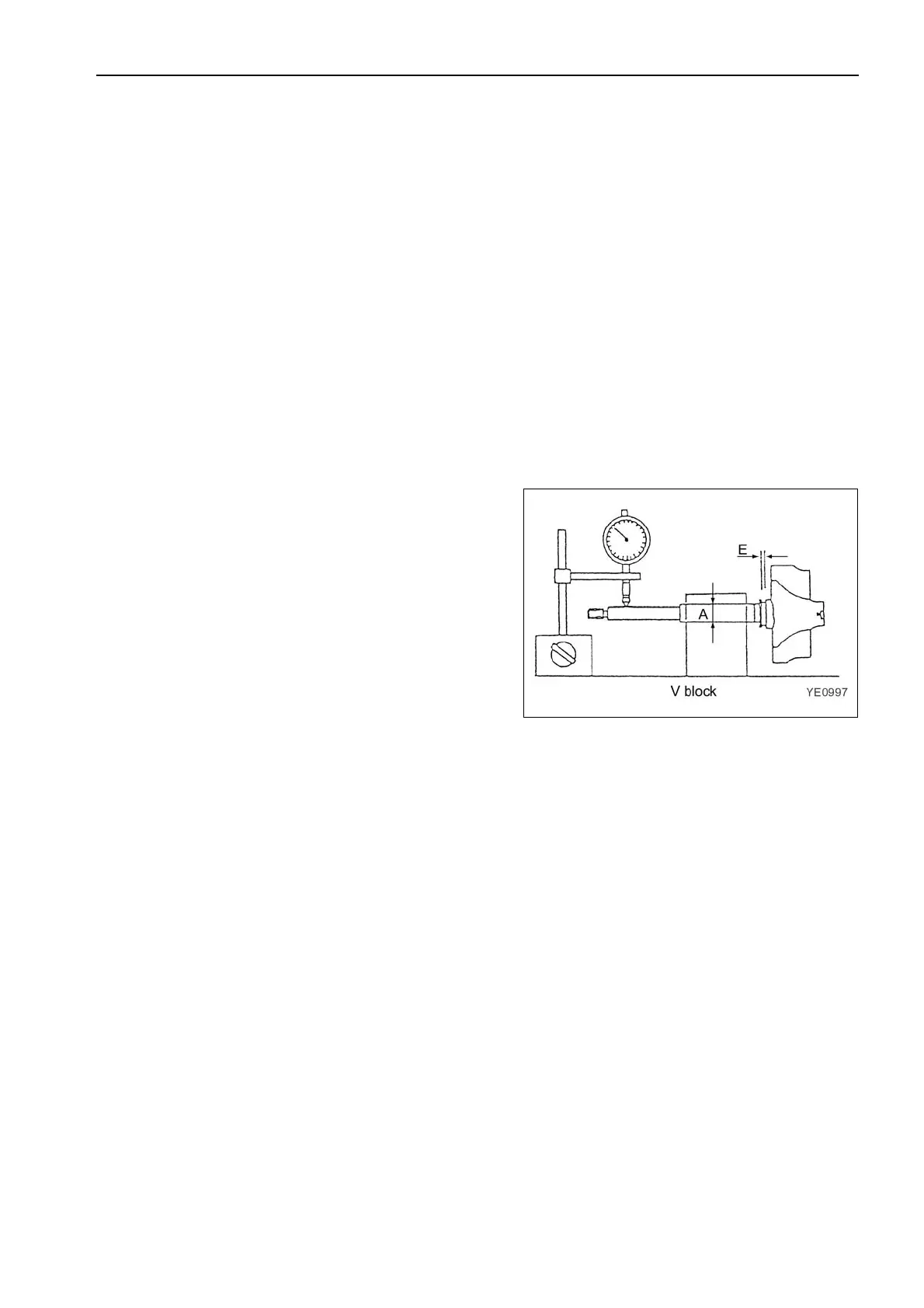

(4) Turbine shaft (1)

1) Inspect any contact trace, chipping, thermal

discoloration or deformation at the turbine

wheel. Check the shaft portion for bend, the

journal portion for thermal discoloration or

abnormal wear, and the seal ring groove for

surface defect or wear. Replace with a new

one if defective.

2) Measure the turbine shaft journal outside

diameter (A) and seal ring groove width (E).

Replace with a new turbine shaft if beyond

the wear limit.

Wear limit of journal outside diameter (A)

RHB51......7.98 mm

RHB31......6.25 mm

Wear limit of ring groove width (E)

RHB51......1.29 mm

RHB31......1.07 mm

3) Measure the turbine shaft run-out, and

replace with a new turbine shaft if it exceeds

0.011 mm.

(5) Heat insulating plate (20)

Inspect the heat insulating plate for any contact

trace, thermal deformation or corrosion. Replace

with a new one if defective.

Loading...

Loading...