128

MAINTENANCE NOTES

4.2 MAINTENANCE NOTES

4.2.1 NOTES REGARDING THE ENGINE

4.2.1.1 ENGINE OIL

4.2.1.2 COOLANT

• Use only Komatsu Utility genuine spare parts.

• Do not mix different types of oil.

• Unless specified otherwise, the oils and the coolant used by Komatsu Utility to fill the tanks before the delivery of

the machine are the following:

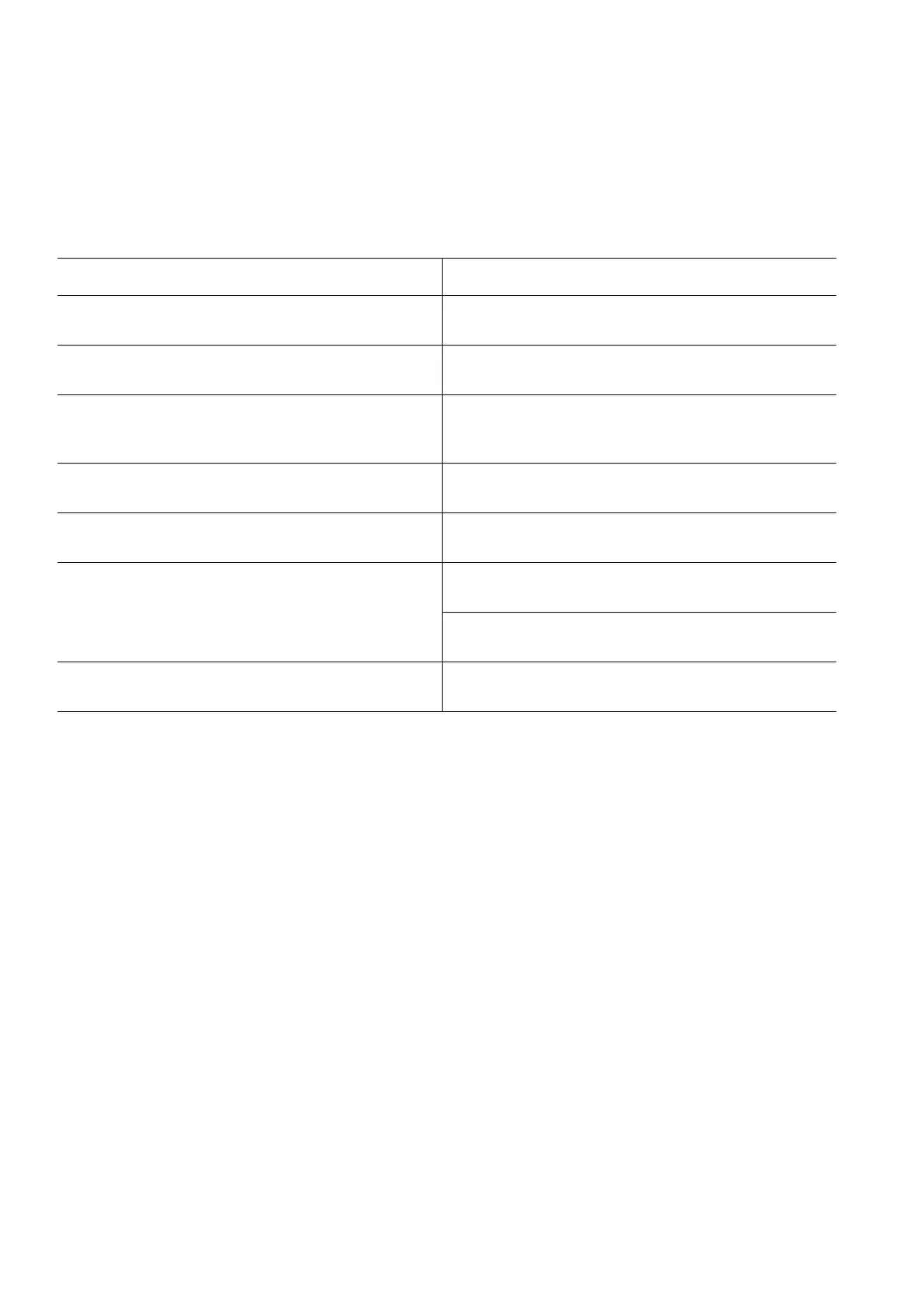

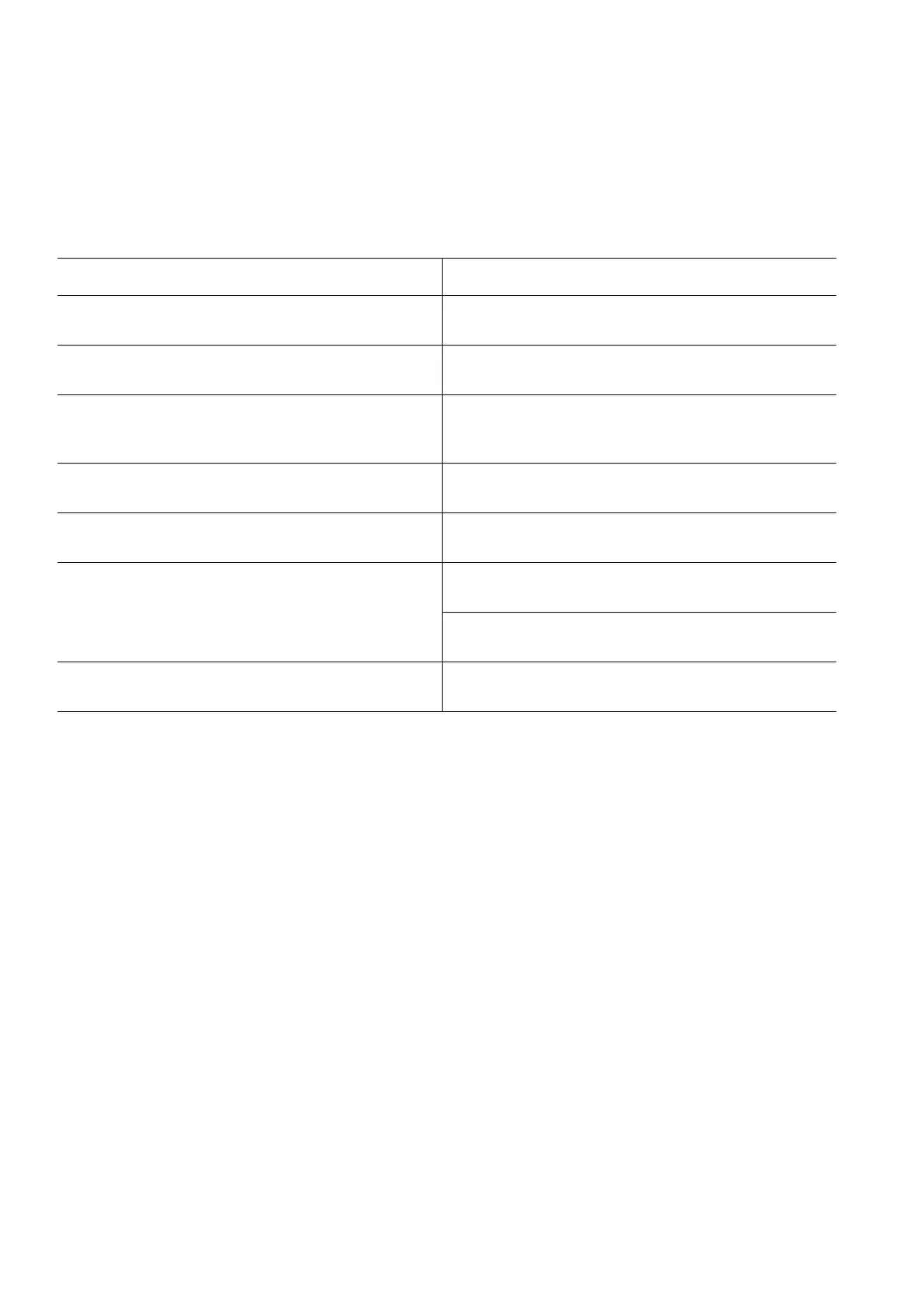

ITEM SPECIFICATIONS

• Engine oil SAE 15W-30

API classification CD

• Hydraulic system oil SAE 10W

API classification CD

• Biodegradable hydraulic system oil

(Only for machines in which the synthetic biode-

gradable oil type HEES not of plant origin is used)

SHELL NATURELLE HFX-32

• Travel reduction gear oil SAE 85W/90

API classification GL5

• Swing reduction gear oil SAE 85W/90

API classification GL5

• Fuel Ambient temperature above -10°C:

ASTM D975 no. 2 diesel oil

Ambient temperature below -10°C:

ASTM D975 no. 1 diesel oil

• Radiator Permanent, ethylene glycol-based antifreeze, with cor-

rosion inhibitor for protection up to -36°C.

• The engine oil must be selected very carefully, since it lubricates the engine, which is the machine’s heart; the

main maintenance operations required for the engine oil are the following:

1 - daily check of the oil level;

2 - check of the oil pollution degree;

3 - periodical change.

• The coolant serves to keep the engine at the correct temperature and therefore to ensure optimal operating con-

ditions; check the coolant level in the expansion tank daily and top up if necessary.

• The coolant containing antifreeze is flammable; do not use naked flames near the coolant and do not smoke

while topping up.

Loading...

Loading...