Loading...

Loading...

Do you have a question about the Komatsu PC110R-1 and is the answer not in the manual?

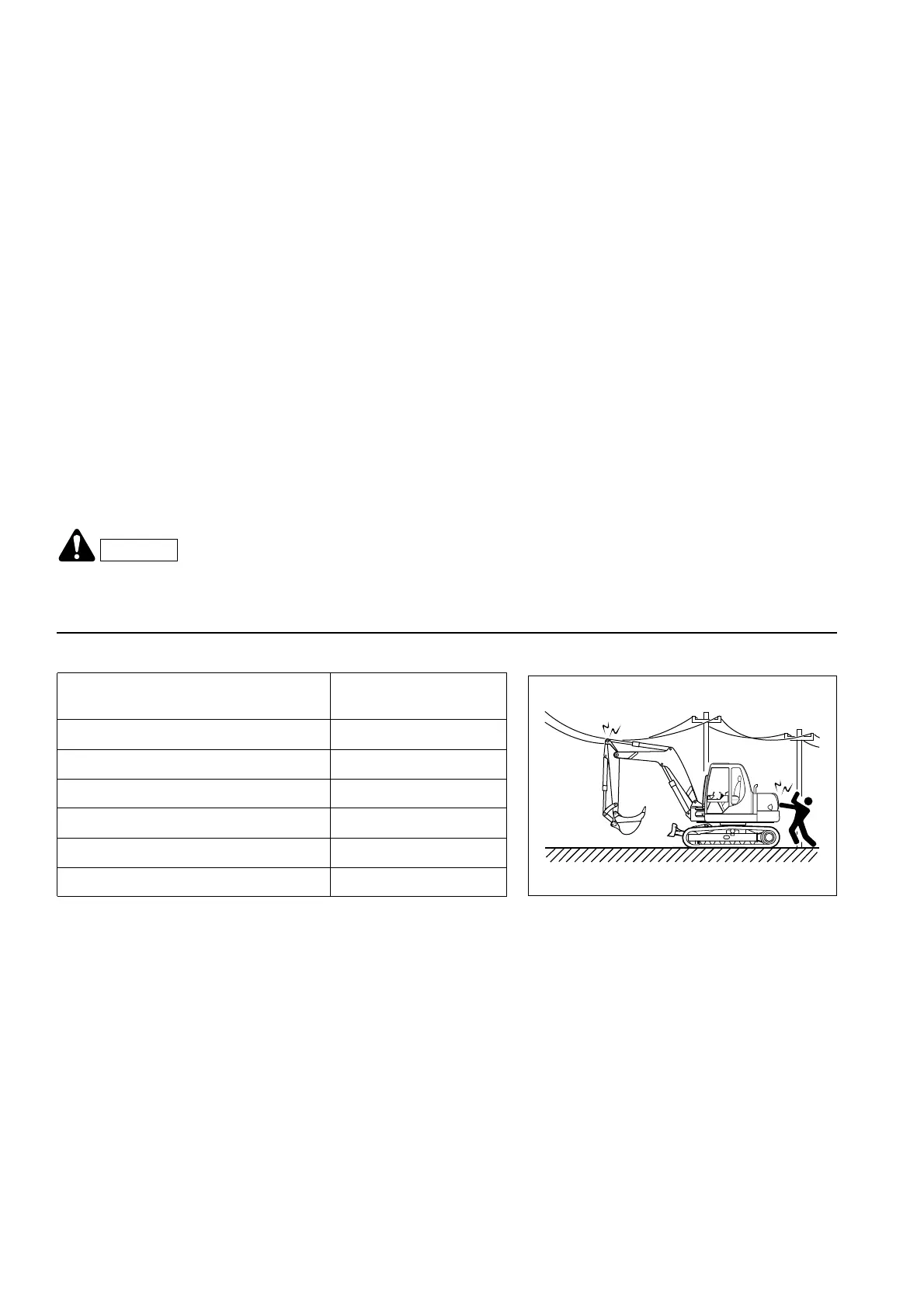

| Brand | Komatsu |

|---|---|

| Model | PC110R-1 |

| Category | Excavators |

| Language | English |

Explains symbols on warning plates and their meanings for safe operation.

Outlines essential safety rules, guards, clothing, and modifications.

Details safety checks for the work site, fire prevention, and cab readiness.

Covers safe operation practices, including starting, moving, and working on slopes.

Details the location and importance of the machine's unique serial number.

Describes the CE mark plate and its compliance with standards.

Identifies and explains the function of key dashboard indicators like hour meter and fuel level.

Explains various warning lights and their meanings for machine status and alerts.

Details the function and location of various operational switches and buttons.

Illustrates and explains the operation of levers, pedals, and other machine controls.

Provides a checklist for essential visual and daily checks before engine startup.

Explains the procedures for starting the engine in warm and cold conditions.

Covers essential steps for safely moving the machine, including steering and slopes.

Details routine checks and lubrication required every 50 operating hours.

Outlines specific checks and adjustments needed every 250 operating hours.

Specifies tasks such as filter changes and fluid checks at 500-hour intervals.

Details major service items like oil changes for reduction gears and coolant replacement.

Provides key dimensions for monoboom and two-piece boom configurations.

Lists specifications for mass, engine, electrical system, and speeds.

Details load capacities based on arm length and working radius.