2-76

PC130/150LGP-6K ENG

12.OPERATION

12.16 REPLACEMENT AND INVERSION OF

BUCKET

• When knocking the pin in with a hammer, metal particles may

fly and cause serious injury, particularly if they get into your

eyes. When carrying out this operation always wear goggles,

helmet, gloves and other protective equipment.

• When the bucket is removed, place it in a stable condition.

Stop the machine on a firm, flat surface. When performing joint work,

make clear signals to each other and work carefully for safety's sake.

12.16.1 REPLACEMENT

1. Place the bucket in contact with a flat surface.

REMARK

When removing the pins, place the bucket so that it is in light contact

with the ground.

If the bucket is lowered strongly to the ground, the resistance will be

increased an it will be difficult to remove the pins.

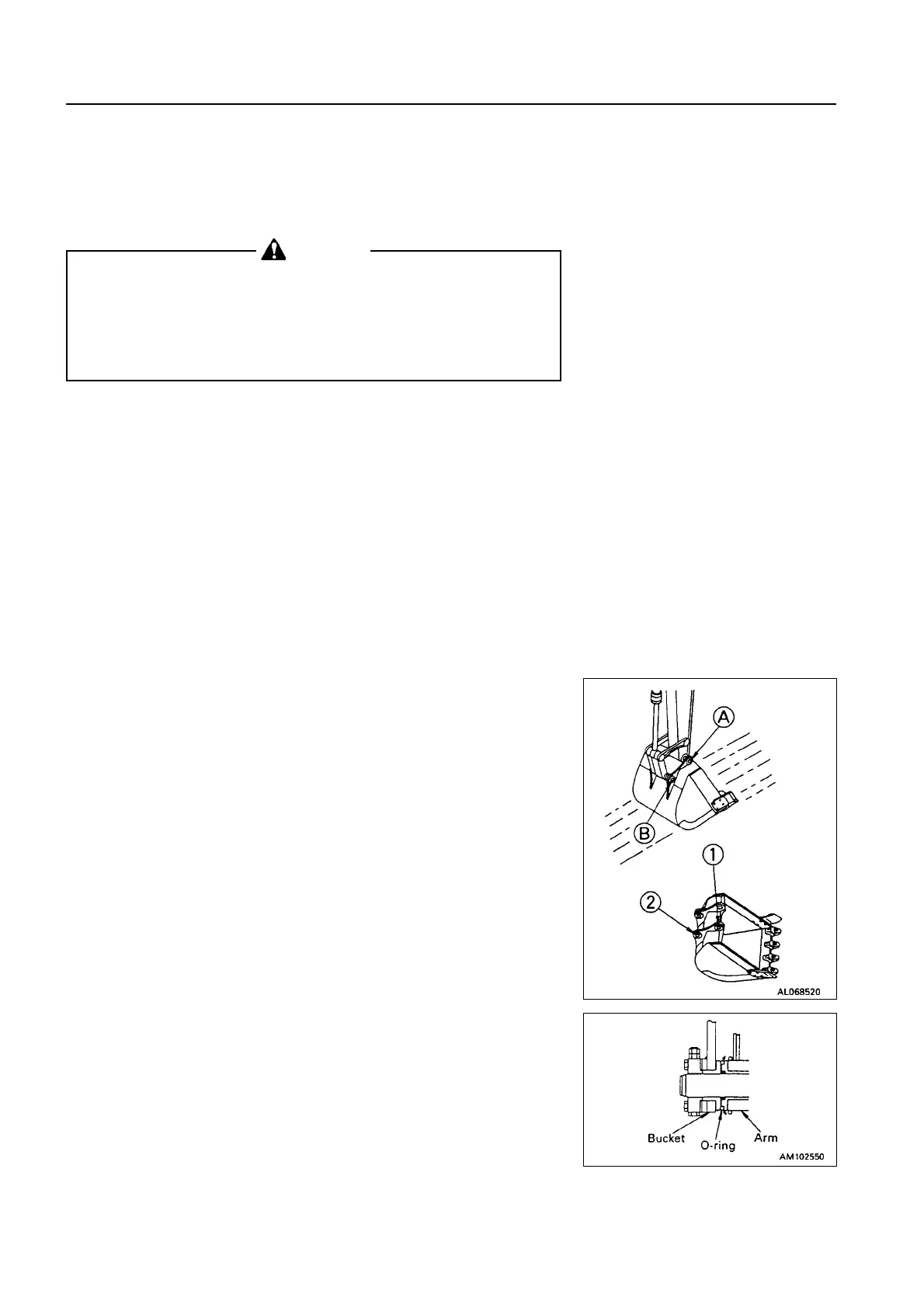

2. Remove the stopper bolts and nuts, then remove pins and , and

remove the bucket

NOTICE

After removing the pins, make sure that they do not become

contaminated with sand or mud and that the seals of bushing on

both sides do not become damaged.

3. Align the arm with holes and the link with holes , then coat with

grease and install pins and .

REMARK

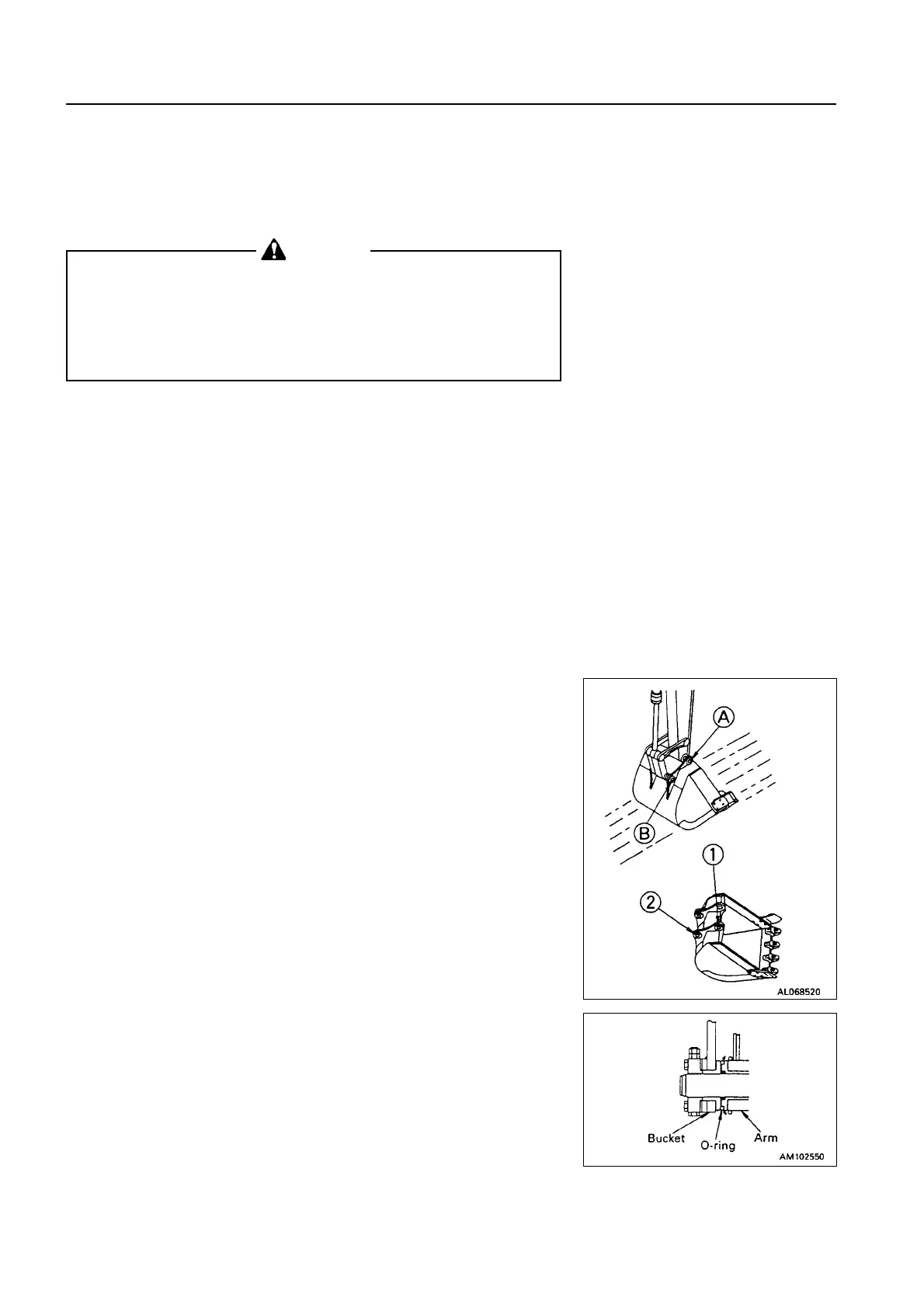

When installing the bucket, the O-rings are easily damaged, so fit the

O-rings on the boss of the arm end as shown in the diagram.

When knocking the pin, move the O-ring down to the regular groove.

4. Install the stopper bolts and nuts for each pin, then grease the pin.

WARNING

Loading...

Loading...