3-60

PC130/150LGP-6K ENG

24. SERVICE PROCEDURE

24.8 EVERY 1000 HOURS SERVICE

Maintenance for every 100, 250 and 500 hours should be carried

out at the same time.

24.8.1 CHANGE OIL IN SWING MACHINERY CASE

The oil is at high temperature immediately after the machine has

been operated. Wait for the oil to cool down before carrying out

maintenance.

• Container to catch drained oil: Min. 2.5 l capacity

• Refill capacity: 2.5 l

1. Set an oil container under drain plug under the machine body.

2. Remove drain plug under the body, drain the oil then tighten the

drain plug again. Tightening torque of the drain plug:

98 - 185 Nm (10 - 19 kgm).

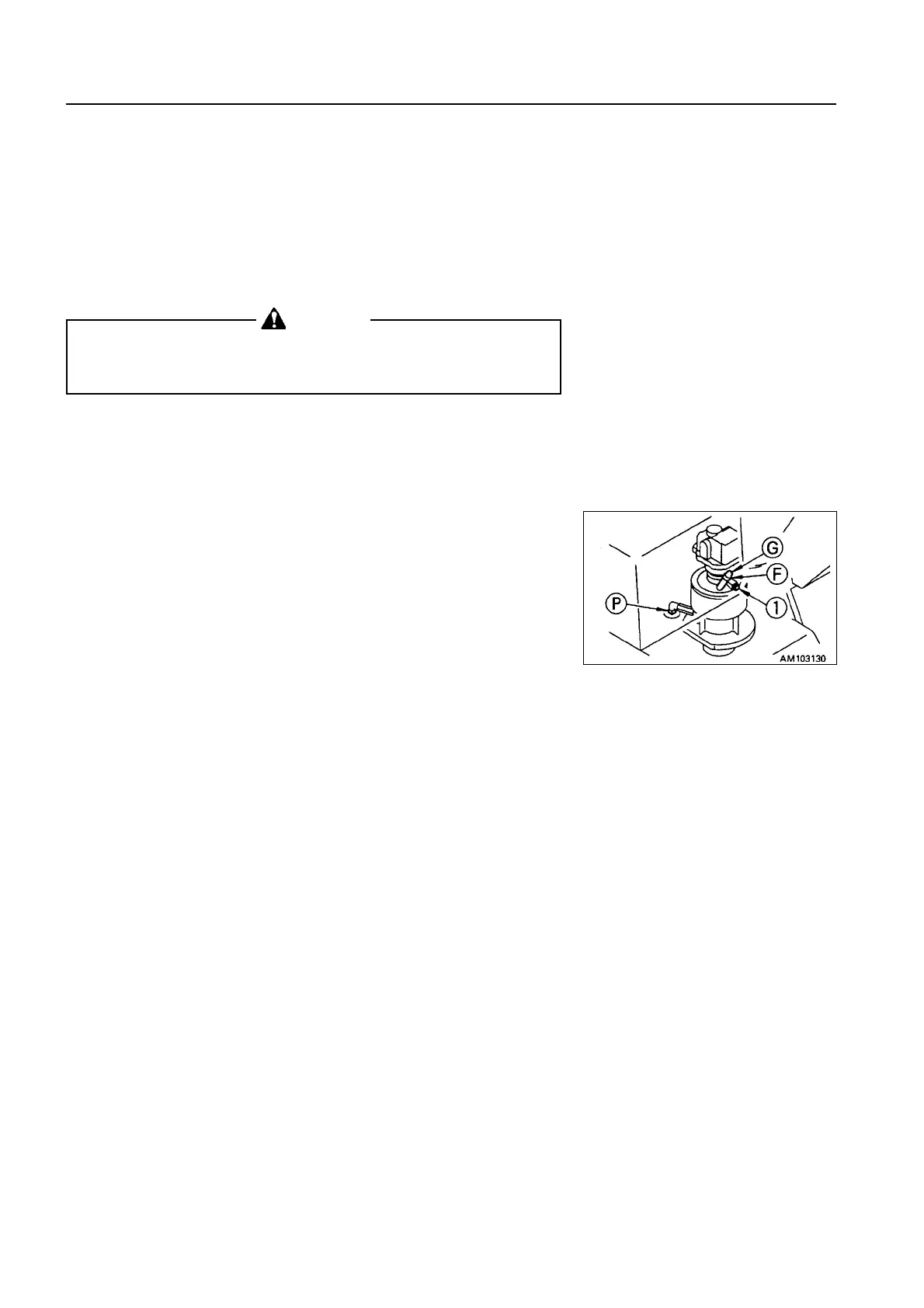

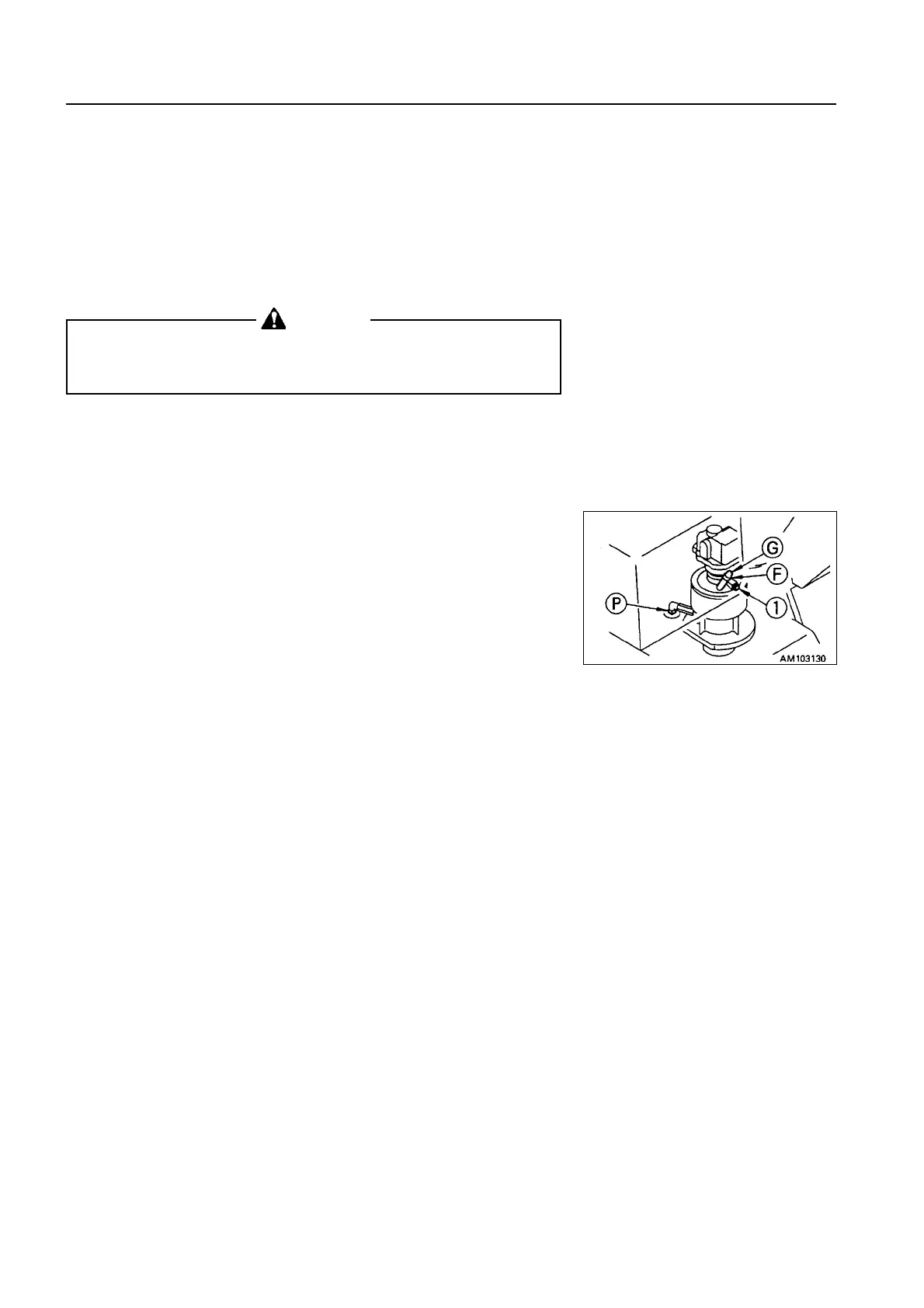

3. Remove dipstick and bleeding plug .

Add the specified amount of engine oil through gauge hole .

NOTICE

For details of the oil to use, see "20. USE OF FUEL, COOLANT

AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE".

4. After refilling, install bleeding plug .

5. Wipe off oil on the dipstick with a cloth.

6. Insert dipstick into the gauge pipe thoroughly and then pull it out

again.

7. When the oil level is between the H and L marks, on dipstick , it is

normal. If the oil does not reach the L mark, add more oil through oil

filter

8. If the oil level exceeds the H mark, drain the excess engine oil from

drain plug , and check the oil level again.

WARNING

Loading...

Loading...