SERVICE PROCEDURE MAINTENANCE

4-32

REPLACE BUCKET TEETH 0.

(If equipped)

WARNING

! If the pin is hit out with strong force, there is danger that the pin may fly out. Check that there is no

one in the surrounding area.

! There is danger of pieces flying during the replacement operation, so always wear protective cloth-

ing, such as safety glasses and gloves.

When the bucket teeth are worn, replace them as follows.

1. Raise the bucket to a suitable height, then put blocks under the bucket to prevent the bucket from coming

down.

Raise the bucket so that the bottom surface of the bucket is horizontal.

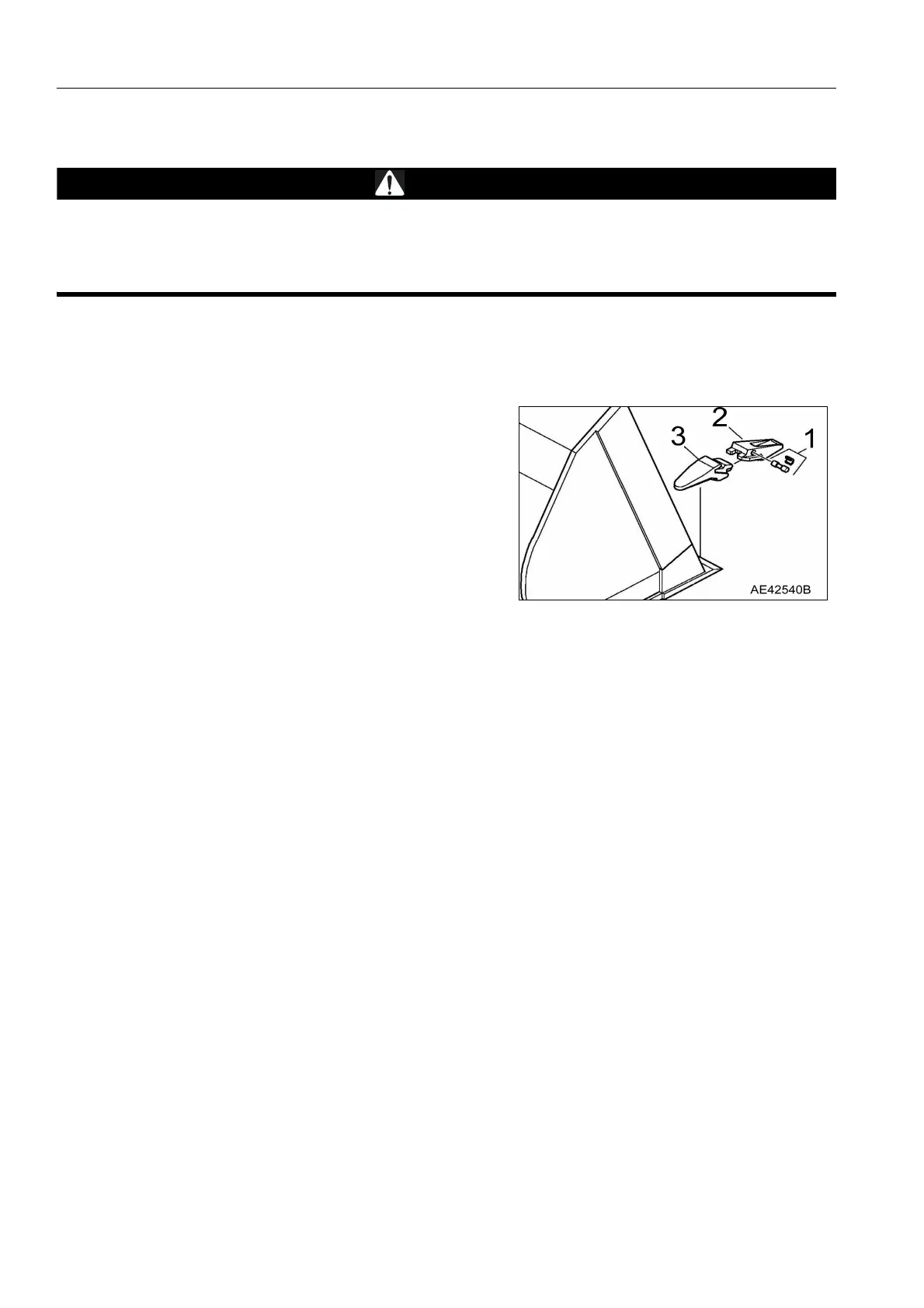

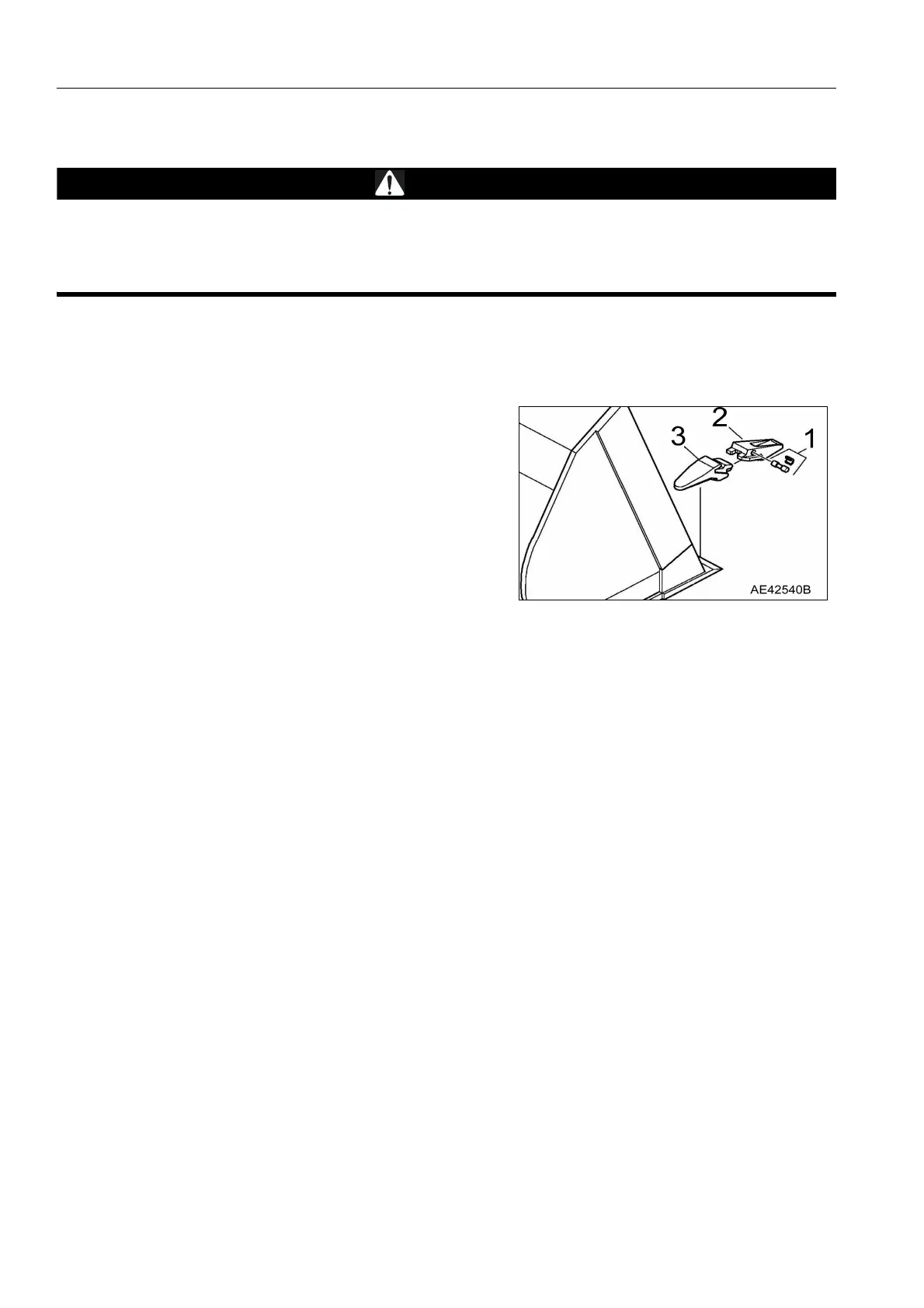

2. Remove the bolt and nuts (1) and (2), then remove bucket

tooth (3).

3. Clean the installation surface of bucket tooth (3).

4. Install new teeth to the bucket.

When doing this, insert shims so that there is no clearance

between the teeth and the top surface of the bucket.

Continue to add shims until it becomes impossible to add a

0.5 mm (0.02 in) shim.

If the mounting surface is worn, correct the mounting surface before installing the teeth.

5. To prevent any gap from forming between the teeth and tip of the bucket, tighten bolts and nuts (1) and (2) tem-

porarily, then hit the tip of the teeth with a hammer.

Tightening torque of mounting bolt (1):

902 ± 39 N²m (92 ± 4 kgf²m, 665.4 ± 28.9 lbft))

Tightening torque of mounting bolt (2):

902 ± 39 N²m (92 ± 4 kgf²m, 665.4 ± 28.9 lbft))

6. After operating the machine for a few hours, tighten the mounting bolts again.

Loading...

Loading...