Page 19

b−HEATING BLOWER"

Place the HEATING BLOWER jumper across the first and

second pins for single−stage heating operation (position

#1). For two−stage operation, place the jumper across the

second and third pins (position #2).

The position of the jumper determines which set of speed

jumpers is activated. When the HEATING BLOWER jumper

is across the first and second pins, the HEAT jumper selec

tions are activated when W1 is energized.

If the jumper is across the second and third pins, the LOW

jumper selections are activated when W1 is energized.

HEAT jumper selections are activated when W2 is ener

gized.

NOTE−In Harmony II zoning applications, HEATING

BLOWER jumper must be in position #2.

c−HEAT"

The HEAT jumper is used to set the blower speed to obtain

the required CFM as outlined in HEAT SPEED section of

the tables on pages 7 and 8.

If a lower heating speed (than one that is listed in HEAT

SPEED section) is required, the LOW jumper may be used

to set the heating speed. This is done by first placing the

LOW jumper in the desired CFM position and then placing

the HTG. BLOWER jumper across the second and third

pins (regardless of the actual stage). Doing so will activate

the low speed jumper setting when W1 is energized.

d−HIGH"

The HIGH jumper is used to determine the CFM during

cooling speed. These jumper selections are activated

when G and DS terminals are energized.

e−LOW"

The LOW jumper is used to determine CFM during low

speed cooling. These jumper selections are activated

when G is energized. The LOW jumper may also be used

for low speed heating. See the HEAT" section for details.

f−FAN OFF"

Fan OFF" timings (time that the blower operates after the

heat demand has been satisfied) are determined by the ar

rangement of a jumper on the VSP2−1 board. See fig

ure 15. To adjust fan OFF" timings, gently disconnect the

jumper and reposition it across pins corresponding with the

new timing. Fan OFF" time is factory set at 270 seconds.

Fan ON" time is factory set at 45 seconds and is not adjust

able.

WARNING − MAKE SURE TO DISCONNECT POWER

BEFORE CHANGING FAN OFF" TIMINGS.

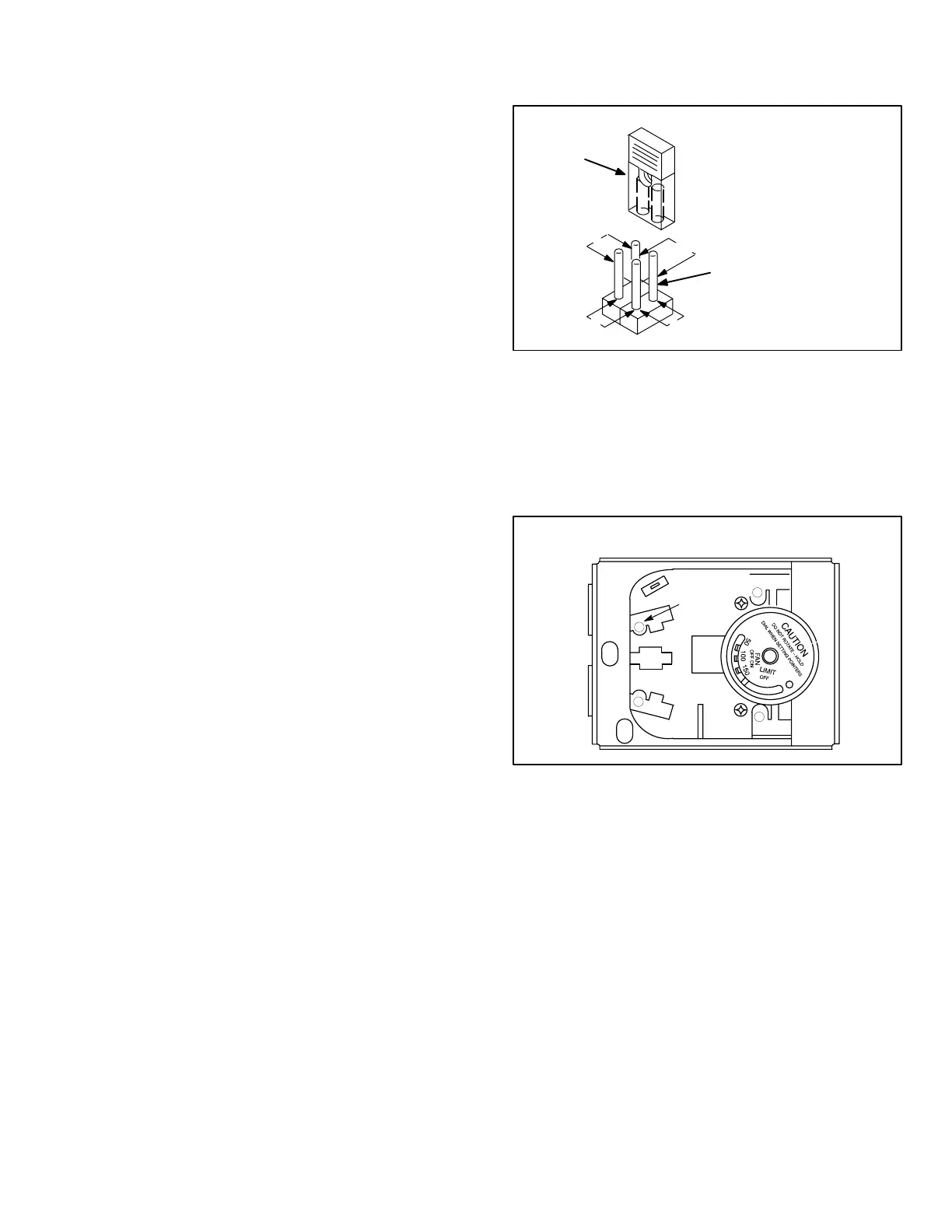

FIGURE 15

FANOFF TIME ADJUSTMENT

270

210

150 90

To adjust fan−off timings:

Remove jumper from VSP2−1 and

select one of the other pin combina

tions to achieve the desired time.

TIMING

JUMPER

TIMING PINS (seconds)

Leave jumper off to achieve

330 second fan−off timing.

Fanoff timing is factory

set at 270 seconds

NOTEIf fan OFF" time is too low, residual heat in heat

exchanger may cause primary limit S10 to trip resulting in

frequent cycling of blower. If this occurs, adjust blower to

longer time setting.

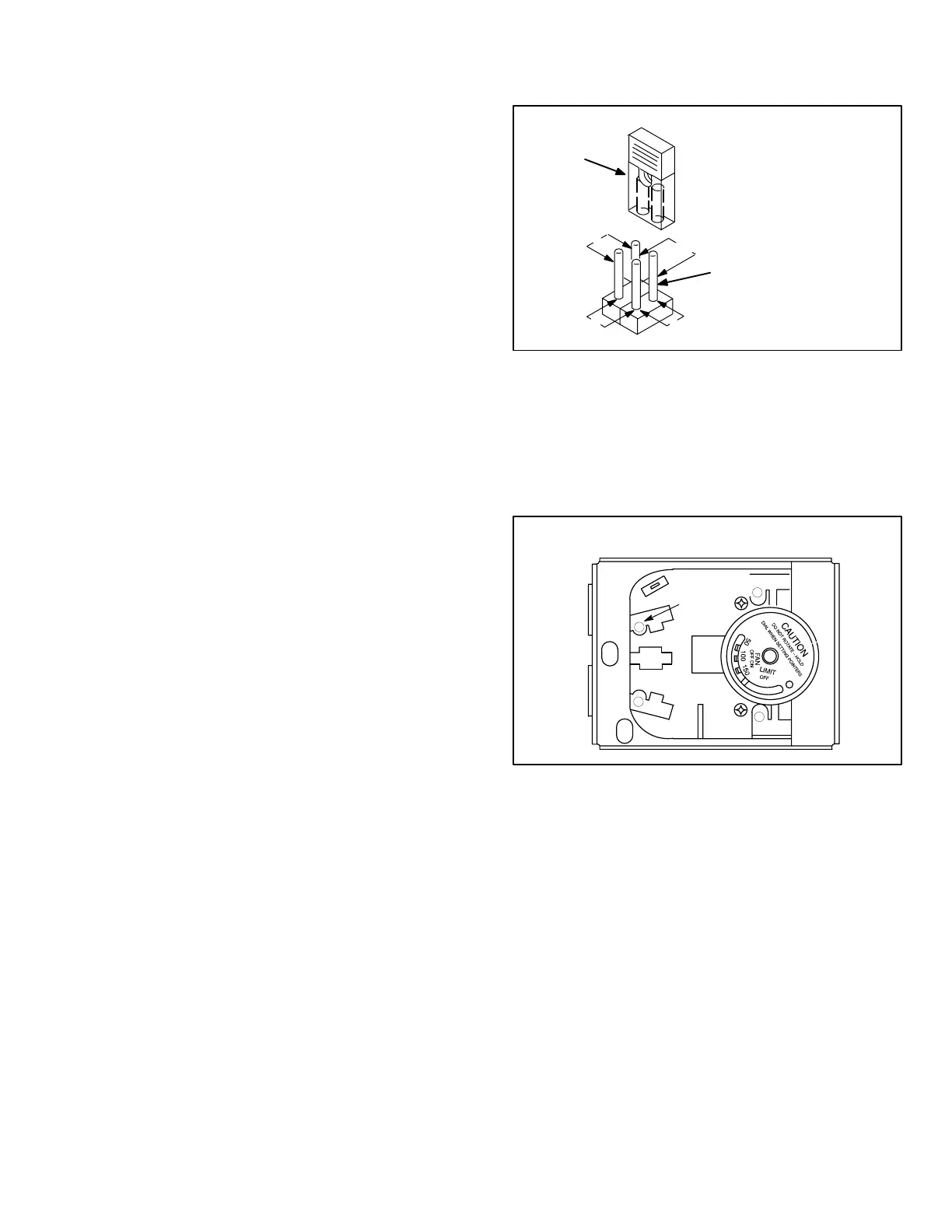

C − LimitControl−Modulation/Limit

Control (Figure 16)

S78 N.O.

HONEYWELL LIMIT CONTROL− MODULATION/

LIMIT CONTROL ALL MODELS S10/S78

FIGURE 16

S78

N.C.

S10

S10

S78 SWING

S78 N.C. IS

A 1/4"

QUICK

CONNECT

1 − Limit Control (S10) Q" Models

G21Q/GSR21Q models use a Honeywell limit control. See

unit components illustration (page 11) for exact location. If heat

exchanger temperatures rise above limit setting (see table 5),

the selfresetting limit interrupts power to ignition control A3,

and fan timing control A28 will maintain the blower to cool

down the unit. This is a safety shut down function. S10 auto

matically resets when temperatures inside the heat exchange

assembly drop below limit setting. Do not change factory limit

setting. S10 is set to limit maximum discharge air temperature.

Loading...

Loading...