GAS METER

TEST

DIALS

CUBIC

FEET

FIGURE 69

Page 50

K − Condensate pH Range

Unit condensate is mildly acidic and can be measured with

pH indicators. The pH scale as shown in figure 68 is a mea

surement of acidity or alkalinity.

Concentration of acidity of all these fluids including con

densate is very low and harmless.

The following scale shows relative pH of some common liquids

as compared with G21/GSR21 condensate.

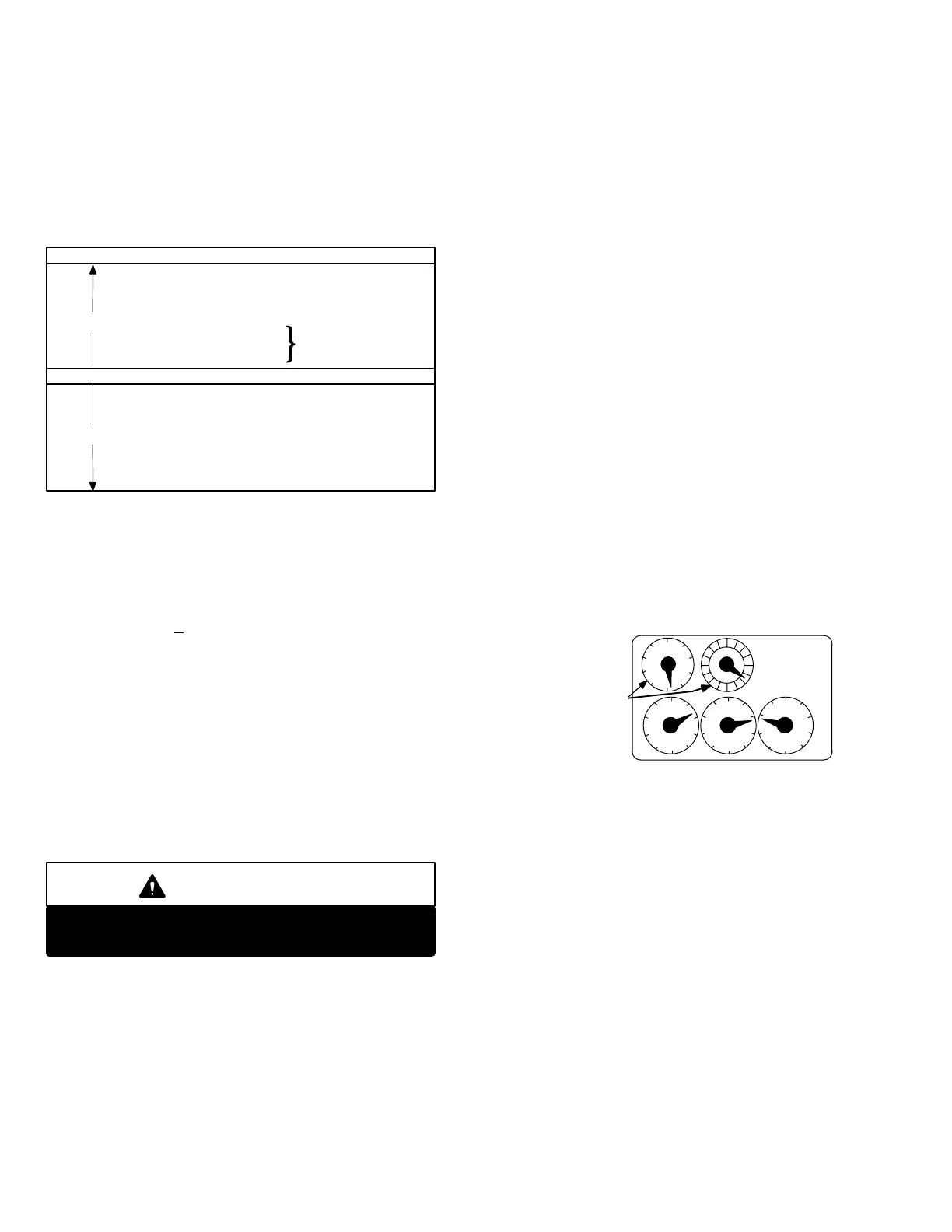

FIGURE 68

pH RANGE

0

1

2− Vinegar

3− Wine

4− Orange Juice

5− Tomato Juice

6

7− tap water

8

9

10

11

12

13

14

Increasing Acidity

Increasing Alkalinity

G21/GSR21

Condensate

Range

L − Acceptable Operating Input

Field adjustments to the unit are not normally needed due to

specifically sized components for each input rating.

Unit may run up to + 3 to 4 percent of rated input (listed on

unit nameplate) due to installation variables such as tem

perature rise, external static pressure and return air tem

perature combined with allowable tolerances of compo

nents within unit. This is an acceptable operating range.

Operation of the G21/GSR21 above or below this accept

able operating range may cause continuity, startup and

lockout problems (erratic operation). Overfiring the unit

can shorten the life of the heat exchanger assembly. Over

firing can be checked by measuring unit’s input.

IMPORTANT

Overfiring the unit can shorten the life of the heat

exchanger assembly

For new units, approximate input measurements may be ob

tained after allowing unit to run continuously for 15 minutes. If

accurate input measurements are required, the following pro

cedure may be used. Accurate input measurements requires

time for the unit to run in."

Run in time allows flapper valves to seat and combustion to

clean the protective layer of oil residue that may be present

from inside surfaces of the heat exchanger assembly. This

process stabilizes combustion rate and may take one to

two hours of continuous operation. Since it is impractical to

operate an installed unit for one to two hours continuously,

the unit should be allowed to operate normally, (cycle on

demand) for a period to accumulate several total hours of

run time to obtain an accurate measurement of input. Over

night operation should provide enough total run time to ob

tain an accurate measurement of input. Just prior to any in

put check, run unit continuously for 15 minutes.

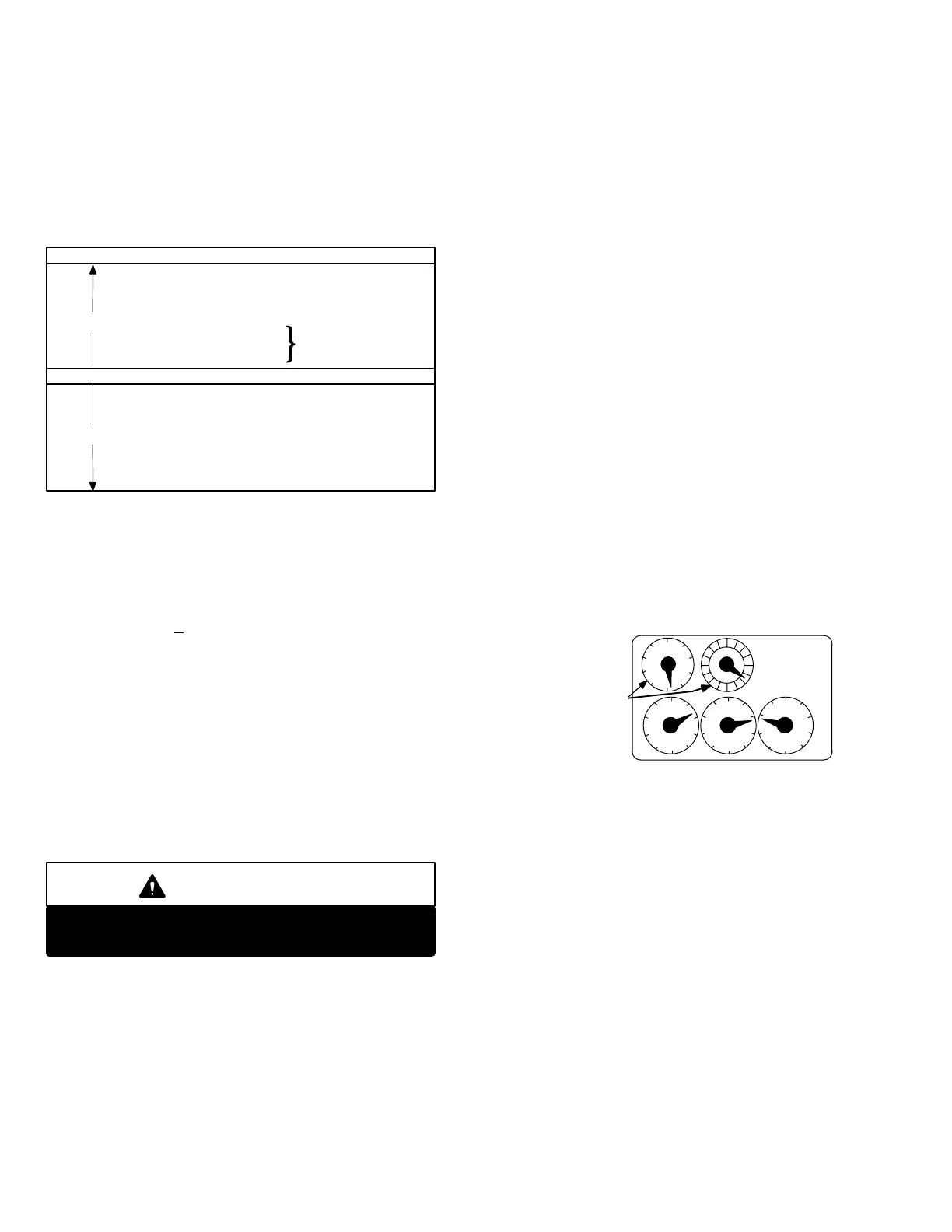

M − Checking Gas InputDetermine Gas

Flow at Meter

1 − Turn off all other gas appliances, including pilot lights

or appliances if used.

2 − For single stage V" units jumper HB to W2.

3 − Set thermostat to highest setting and allow unit to

run continuously for 15 minutes. A 15 minute run

time is needed to allow unit operating rate to stabi

lize.

4 − At the gas sup

ply meter and

using either

one, two,

three or five

foot dial on the

meter, time

one full revolu

tion (in sec

onds) with a watch. See figure 69.

5 − Find the number of seconds for one revolution on the

Gas Rate chart, see table 16 . Read the cubic feet for

matching one, two, three or fivefoot dial size from

table 16 multiply this times Btuh per cubic foot content of

the gas. The result is total gas Btuh input.

6 − Check Btuh input figure against Btuh listed on unit

nameplate.

Loading...

Loading...