SPARK PLUG/SENSOR

REMOVAL TOOL

LENNOX PART # 20H43

FIGURE 29

Page 27

created in the combustion chamber, the flapper is drawn to

the clearance plate and air enters. Once ignition has oc

curred, back pressure and negative pressure control the

flapper valve with each combustion pulse.

L − Spark Plug & Sensor (Figure 28)

IMPORTANT

Units with GC3 ignition controls require a ceramic

resistor spark plug.

IMPORTANT

The spark plug is torqued to 130 + 5 foot/lbs. The

sensor is torqued to 85 + 5 foot/lbs. Allow metal to

cool before measuring torque.

The spark plug is used in conjunction with the primary con

trol for igniting the initial gas and air mixture and is only

used during startup.

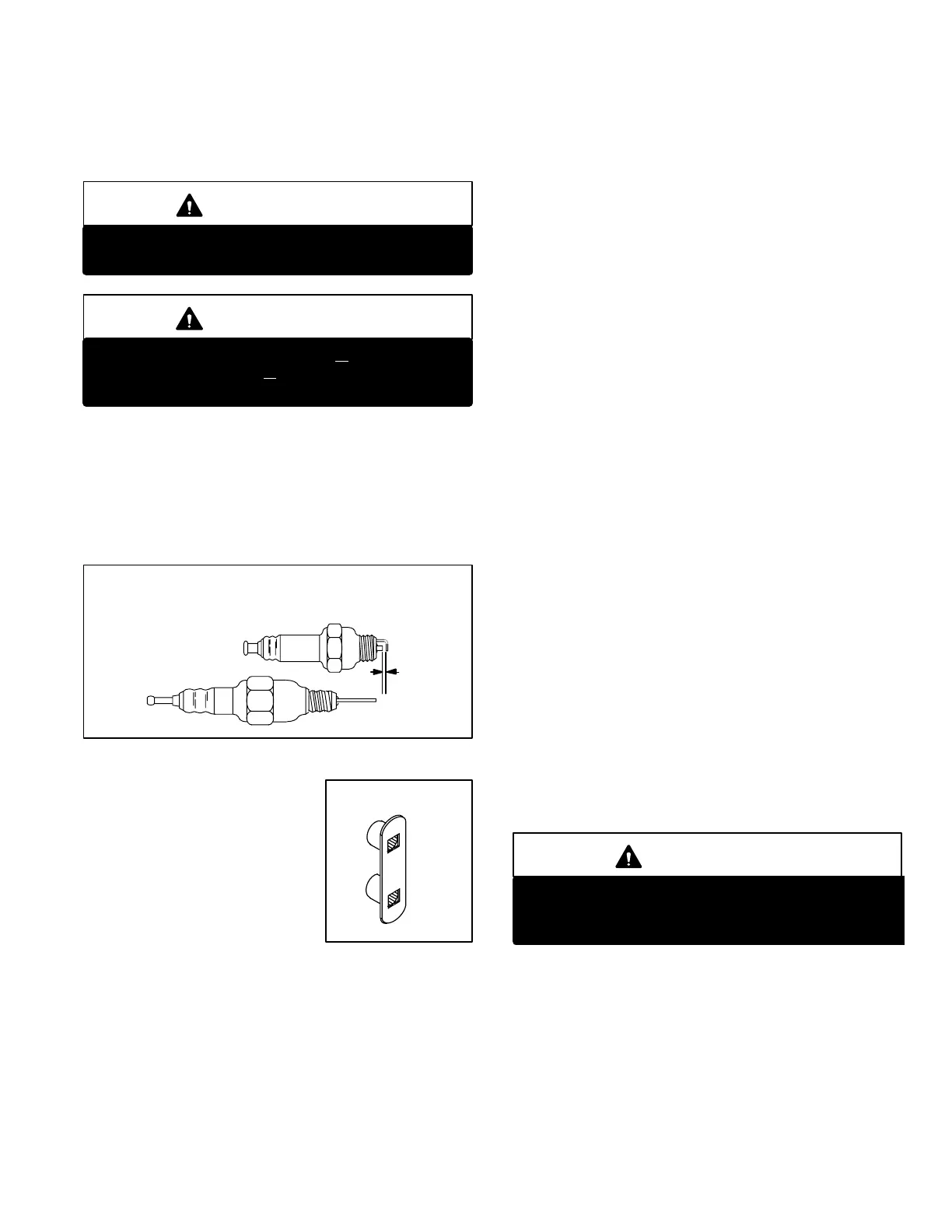

Figure 28 gives the proper spark gap setting. Note the un

usual electrode angle in comparison to other spark plug ap

plications. A feeler gauge can be used to check the gap.

FIGURE 28

NOTE Carbon resistor type

plugs should not be used.

CHAMPION FI21500 or

equivalent only

SPARK PLUG

.113 to .118

SENSOR

Temperatures in the combustion

chamber keep the plug free from ox

ides. It should not need regular

maintenance. Compression rings

are used to form a seal to the cham

ber.

The spark plug type sensor has a

single electrode (no ground strap).

Compression rings are used to

form a seal to the chamber. It also should not need regular

maintenance. Removal of the plug/sensor is aided by a

Lennox spark plug/sensor removal tool. See figure 29. It is

available from Lennox Repair Parts, part no. 20H43.

The spark plug and sensor are located on the left side of the

combustion chamber, see figures 30 and 31 for exact loca

tion. The sensor is the top plug and is longer than the spark

plug. The spark plug is in the lower position. Plugs cannot be

interchanged due to different thread diameters.

M − Combustion Chamber & Heat Exchanger

Assembly (Figures 30 and 31)

1 − Combustion Chamber

The combustion chamber has gas and air intake manifolds.

See figures 30 and 31 for exact location. Exhaust gas leaves

through the tailpipe at the top of the chamber.

2 − Tailpipe

The tailpipe connects the combustion chamber to the exhaust

gas decoupler. The tailpipe and decoupler create the proper

amount of back pressure for combustion to continue and are

major heat exchanger components. The resonator provides

attenuation for acoustic frequencies. See figures 30 and 31

for exact location.

3 − Exhaust Decoupler

The exhaust decoupler is manifolded into the condenser

coil. Latent heat of combustion is extracted from exhaust

gas in the condenser coil. When this is done, condensate

(moisture) is produced. The circuiting of the coil allows for

proper drainage of condensate to the exhaust outlet line.

See figures 30 and 31 for exact location.

4 − Heat Exchanger Assembly

Each unit input size uses a specific heat exchanger assem

bly. Externally, they may appear the same, but THEY

MUST NOT BE INTERCHANGED between unit input

sizes. Internal characteristics related to unit input properly

match each assembly for unit input rating. See figures 30

and 31 for exact location.

The entire heat exchange assembly is mounted on rubber

isolation mounts to eliminate vibration.

IMPORTANT

If heat exchanger must be replaced, keep orifice

from the old heat exchanger. New orifices are not

supplied with replacement heat exchangers.

N − Gas & Air Components Applied to Heat

Exchanger

Figures 30 and 31 identify all of the components of the ba

sic heating assembly.

Loading...

Loading...