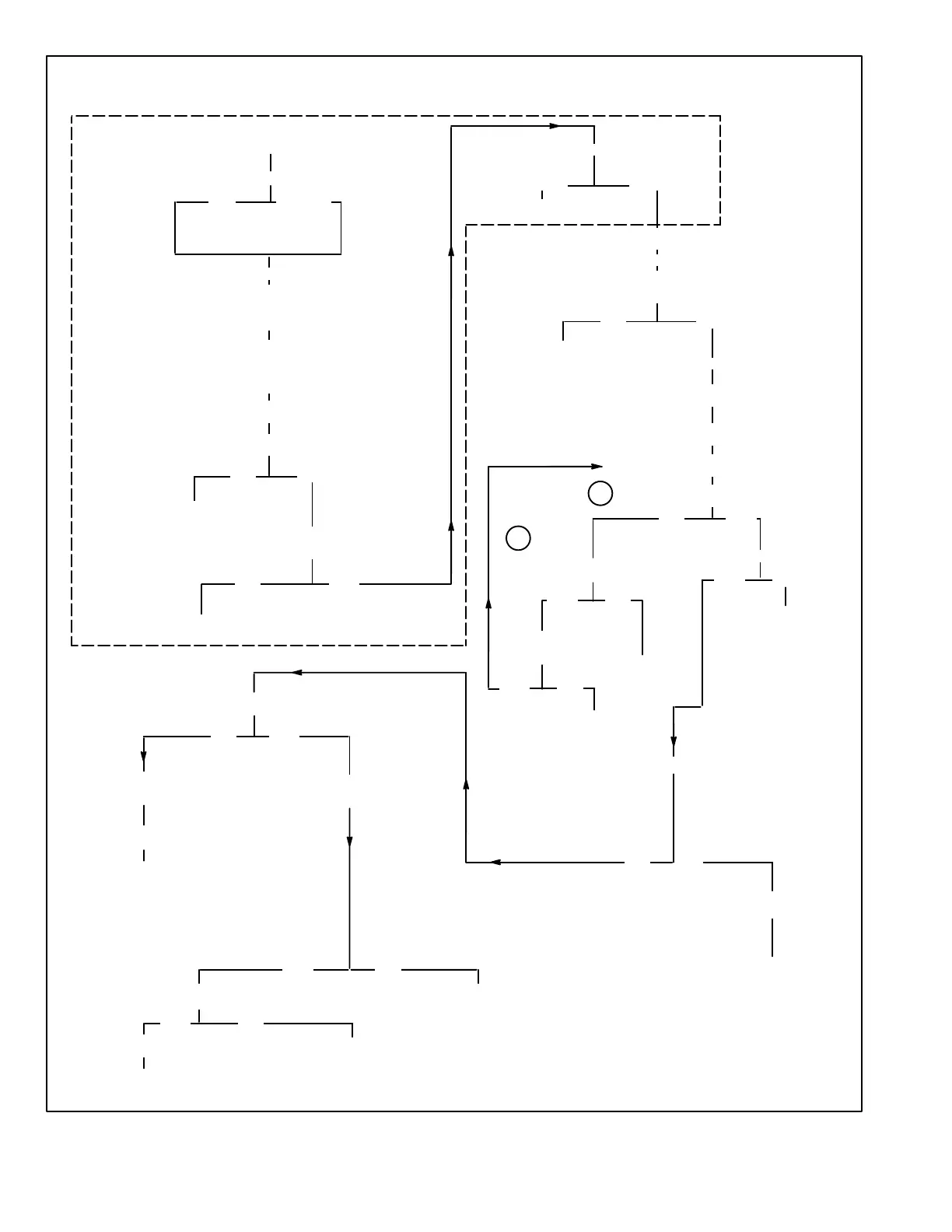

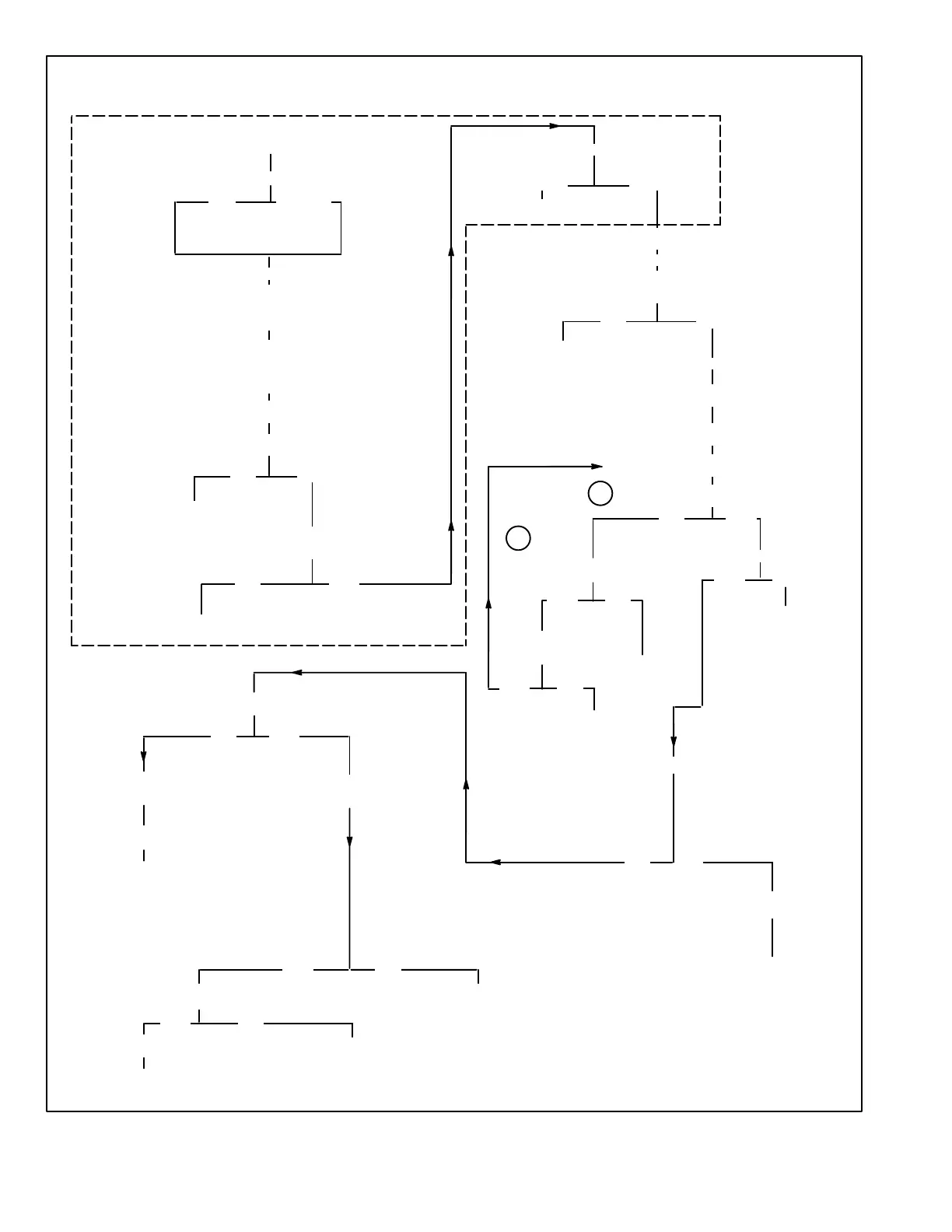

Page 66

NO YES

NO YES

REFER TO INSTALLATION INSTRUCTIONS: ARE IN

TAKE & EXHAUST LINES PROPERLY SIZED & AP

PLIED WITHIN LENGTH, DIAMETER & ELBOW LIMITS?

YES NO

NO YES

YES NO

NO YES

IS GAS SUPPLY NATURAL OR L.P.?

L.P. NATURAL

HAS L.P. CONVERSION KIT

BEEN INSTALLED?

IF NOT, INSTALL KIT.

IS GAS SUPPLY ON?

1. CHECK SUPPLY VALVE.

2. CHECK STOP VALVE AT UNIT.

3. CHECK MANUAL KNOB ON

GAS VALVE IN UNIT.

CHECK FOR LEAKS IN GAS SUPPLY

PIPING & REPAIR IF NEEDED.

AIR IN GAS PIPING?

BLEED AIR BY RUNNING UNIT THROUGH SEVERAL

TRIES FOR IGNITION. BREAK & REMAKE THERMOSTAT

DEMAND TO RESTART IGNITION SEQUENCE AT 2 TO 3

MINUTE INTERVALS.

CAUTIONDO NOT USE MATCH OR FLAME

TO CHECK FOR GAS LEAKS.

GAS

CHECKS

CHECK FOR LEAKS IN UNIT MANIFOLD PIPING.

LEAKS NO LEAKS

VISUALLY CHECK OUTSIDE TERMINATIONS OF

INTAKE & EXHAUST PVC PIPING FOR OBSTRUCTIONS.

VISUALLY CHECK CONDENSATE DRAIN FOR OBSTRUCTIONS.

CORRECT PIPING

ERRORS & RETEST.

TURN OFF GAS TO UNIT.

CHECK PURGE BLOWER FOR BINDING

OR MECHANICAL DAMAGE.

BREAK & REMAKE THERMOSTAT DEMAND

TO INITIATE CONTROL SEQUENCE.

IS120VAC PRESENT ACROSS PURGE

BLOWER MOTOR TERMINALS?

NO YES

IS 120VAC PRESENT BETWEEN

JP72−6 AND COMMON?

DOES PURGE BLOWER RUN?

REPLACE

PURGE BLOWER.

REPLACE

PRIMARY CONTROL.

CHECKOUT

WIRING

CONNECTIONS

& REPAIR.

IS DIFFERENTIAL PRESSURE SWITCH CUTTING OUT?

IF NO BLOCKAGE EXISTS

REPLACE DIFFERENTIAL PRESSURE

SWITCH.

3. REPLACE SENSOR IF

CRACKED?

2. ARE CRACKS PRESENT IN PORCELAIN?

1. WAS PLUG TIGHT WHEN REMOVED?

IS GAS VALVE ACTUALLY OPENING?

DETERMINE BY CHECKING FOR MANIFOLD

PRESSURE DURING TRIALS FOR IGNITION.

REPLACE GAS VALVE.

CORRECT

GAS PRES

SURE.

AIR

CHECKS

REMOVE AIR INTAKE CHAMBER COVER

(USE CARE TO PREVENT DAMAGE TO COVER GASKET).

8

9

REPAIR LEAKS

& RETEST.

UNIT SPUTTER STARTS AND DIES

MAKE OHM METER CHECK ACROSS

TERMINALS IMMEDIATELY AFTER

UNIT SHUTS OFF. METER READS

INFINITE( )OHMS WHEN SWITCH

CUTS UNIT OUT.

8

CHECK FOR PARTIAL BLOCKAGE

OF ALL PVC PIPING & CONDENSATE

LINE.

IS FLAME SIGNAL PRESENT AND COR

RECT?

CHECK WITH MICROAMP METER

NO YES

CHECK SENSOR WIRE

REPLACE IF DETERI

ORATED

& RETEST UNIT

IS AIR FLAPPER VALVE OPERATING NORMALLY?

(LACK OF AIR?) REFER TO

CHECKING AIR INTAKE FLAPPER VALVE"

REPLACE ORIFICE

IF

NECESSARY

IS GAS ORIFICE CORRECT?

REFER TO CHECKING GAS ORIFICE"

NOYES

IS GAS FLAPPER OPERATING NORMALLY?

REFER TO CHECKING GAS FLAPPER VALVE

YES

REPLACE GAS FLAPPER VALVE

NO

REPLACE AIR FLAPPER VALVE OR MATERIAL

IS 120VAC PRESENT

BETWEEN

JP72−6 AND JP72−5?

YES NO

REMOVE & CHECK SPARK PLUG (USE LENNOX

PART #20H43 OR 3/4" SPARK PLUG SOCKET).

START HERE

Loading...

Loading...