Page 51

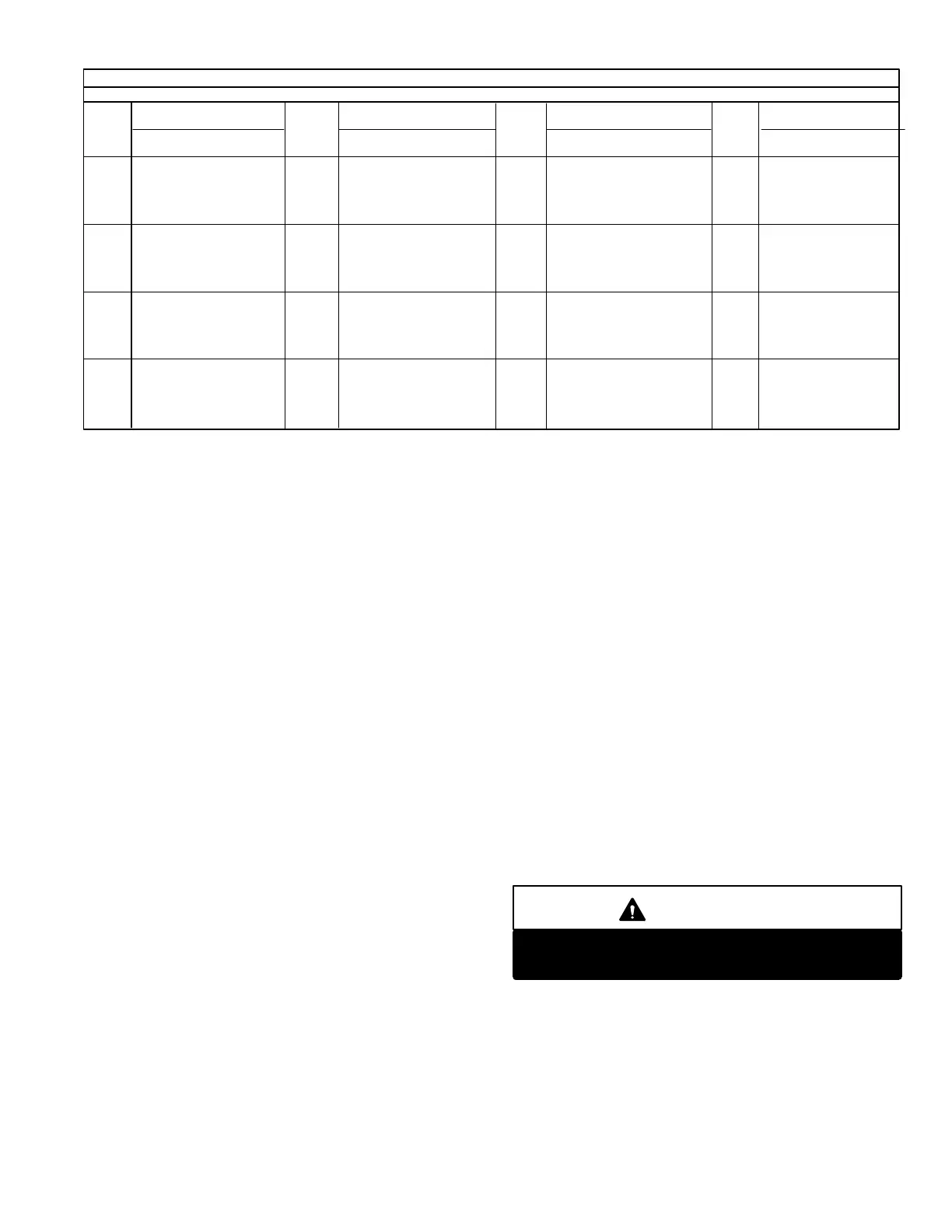

TABLE 16

METER FLOW RATE

GAS RATE CUBIC FEET PER HOUR

Secs

for

One

Rev.

1

cu. ft.

2

cu. ft.

5

cu. ft.

Secs

for

One

Rev.

1

cu. ft.

2

cu. ft.

5

cu. ft.

Secs

for

One

Rev.

2

cu. ft.

5

cu. ft.

Secs

for

One

Rev.

Size of Test Dial

10 360 720 1800

11 327 655 1636

12 300 600 1500

13 277 555 1385

14 257 514 1286

15 240 480 1200

34 106 212 529

35 103 206 514

36 100 200 500

37 97 195 486

38 95 189 479

39 92 185 462

62 116 290

64 112 281

66 109 273

68 106 265

70 103 257

72 100 250

165 − 109

170 − 106

175 − 103

180 − 100

− − −

2

cu. ft.

5

cu. ft.

53 136 340

55 131 327

57 126 316

59 122 305

− − −

− − −

51 141 353

16 225 450 1125

17 212 424 1059

18 200 400 1000

19 189 379 947

20 180 360 900

21 171 343 857

22 164 327 818

23 157 313 783

24 150 300 750

25 144 288 720

26 138 277 692

27 133 267 667

28 129 257 643

29 124 248 621

30 120 240 600

31 116 232 581

32 113 225 563

33 109 218 545

52 69 138 346

54 67 133 333

56 64 129 321

58 62 124 310

60 60 120 300

− − − −

46 78 157 391

47 − 153 383

48 75 150 375

49 − 147 367

50 72 144 360

− − − −

40 90 180 450

41 − 176 439

42 86 172 429

43 − 167 419

44 82 164 409

45 80 160 400

100 72 180

102 − 176

104 69 173

106 − 170

108 67 167

98 − 184

86 84 209

88 82 205

90 80 200

92 78 196

94 − 192

96 75 188

74 97 243

76 95 237

78 92 231

80 90 225

82 88 220

84 86 214

110 − 164

112 64 161

116 62 155

120 60 150

125 − 144

130 − 138

135 − 132

140 − 129

145 − 124

150 − 120

155 − 116

160 − 113

Size of Test Dial Size of Test Dial Size of Test Dial

EXAMPLE:

a − One revolution of twofoot dial = 90 seconds.

b − Using the gas rate chart, table 16, note that 90 sec

onds = 80 cubic feet of gas per hour.

c − 80 cu. ft./hr. x 1000 Btuh/cu. ft. = 80,000 Btuh in

put.

d − Normally there are 1000 Btuh in each cubic foot of

gas. Make adjustment to this figure where the gas

heating value is other than 1000 Btuh per cubic

foot (contact the local gas supplier for local Btuh

per cubic foot ratings).

N − Checking Air Intake and Flapper Valve

Figures 70, 71 and 72

1 − Remove air intake chamber cover and check foreign

materials that may have accumulated, clean purge

blower and upper and lower chamber compartment if

necessary.

2 − Do not remove air flapper valve unless it is suspected

of being faulty.

If valve must be removed, carefully remove the eight

screws holding air intake flapper valve to valve body. DO

NO TURN OR REMOVE CENTER SCREW. Remove

valve from unit. CAUTIONDO NOT DROP.

3 − EXTREME CARE SHOULD BE TAKEN WHEN DISAS

SEMBLING INTERNAL COMPONENTS OF THE

VALVE. If taken apart, plates could be rotated out of

phase or reversed. Spacer thickness has an extremely

low tolerance. Note that each plate has a stamp of the

spacer thickness and a star or the words THIS SIDE

OUT." These stamps should all lie in the same quadrant

and face the outside of unit. See figures 71 and 72. New

er air flapper valve assemblies for the −40 / 50 / 60 / 80

contains a plate made from PPS thermoplastic with a

grooved surface on one side. The grooved surface should

be facing towards the flapper. Earlier −40/50/60/80 models

will have a stainless steel back plate with a star stamped

on the surface. This star must face away from the flapper

when assembled. On all −40/50/60/80 models, the front

plate will have a stamp and star on the surface and must

face away from flapper.

4 − Visually inspect flapper. On new units, the flapper may

not be perfectly flat, it may be curved or dished between

the plates. This is normal. On units that have had suffi

cient run in time, the flapper will be flat. If the flapper is torn,

creased or has uneven (frayed) edges, the material must

be replaced. A flapper material is available from Lennox

Repair Parts. Flapper should be replaced every four

years.

5 − To find potential warpage in the plates, check for the re

quired clearance between the flapper and back plate in

several places around the circumference of the valve.

See figure 73. Use a feeler gauge, starting small and

working up to the clearance dimension until the gauge

is just about snug.

WARNING

Do not force feeler gauge between flapper and

back plate. Damage to flapper material will occur.

Clearance should be checked in six or eight places

around the valve. If valve is out of clearance at any

one point, replace the assembly. Required clear

ance values are listed in table 17. Clearances are

updated regularly in Service and Application Notes.

Loading...

Loading...