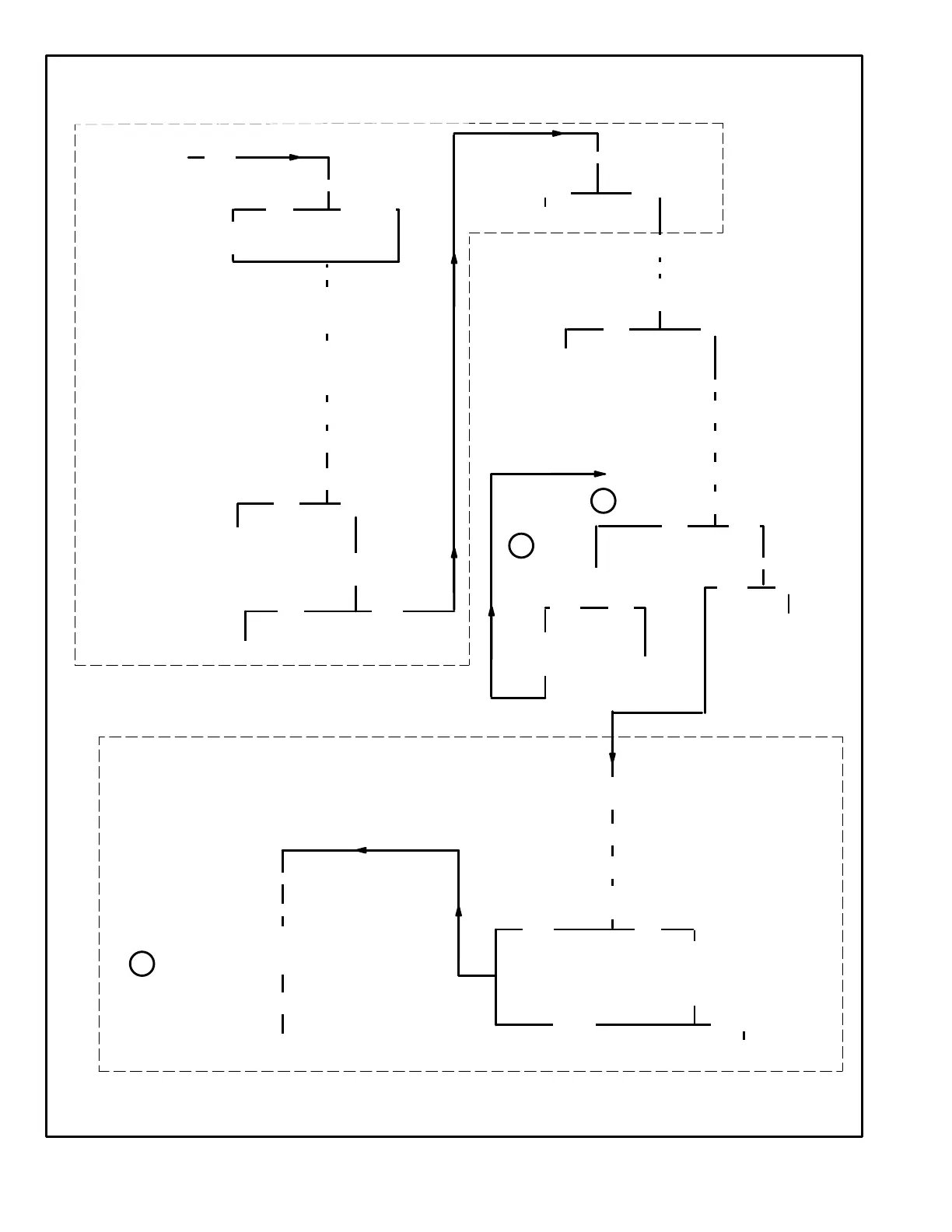

Page 60

CONTINUED FORM

UNIT WILL NOT RUN

FLOW CHART ON

PREVIOUS PAGE

NO YES

NO YES

REFER TO INSTALLATION INSTRUCTIONS: ARE IN

TAKE & EXHAUST LINES PROPERLY SIZED & AP

PLIED WITHIN LENGTH, DIAMETER & ELBOW LIMITS?

YES NO

YES

NO YES

YES NO

IS GAS SUPPLY NATURAL OR L.P.?

L.P. NATURAL

HAS L.P. CONVERSION KIT

BEEN INSTALLED?

IF NOT, INSTALL KIT.

IS GAS SUPPLY ON?

1. CHECK SUPPLY VALVE.

2. CHECK STOP VALVE AT UNIT.

3. CHECK MANUAL LEVER OR SWITCH

ON GAS VALVE IN UNIT.

CHECK FOR LEAKS IN GAS SUPPLY

PIPING & REPAIR IF NEEDED.

AIR IN GAS PIPING?

BLEED AIR BUY RUNNING UNIT THROUGH SEVERAL

TRIES FOR IGNITION. BREAK & REMAKE THERMOSTAT

DEMAND TO RESTART IGNITION SEQUENCE AT 2 TO 3

MINUTE INTERVALS.

CAUTIONDO NOT USE MATCH OR FLAME

TO CHECK FOR GAS LEAKS.

GAS

CHECKS

CHECK FOR LEAKS IN UNIT MANIFOLD PIPING.

LEAKS NO LEAKS

REPAIR LEAKS

& RETEST.

VISUALLY CHECK OUTSIDE TERMINATIONS OF

INTAKE & EXHAUST PVC PIPING FOR OBSTRUCTIONS.

VISUALLY CHECK CONDENSATE DRAIN FOR OBSTRUCTIONS.

CORRECT PIPING

ERRORS & RE

TEST.

TURN OFF GAS TO UNIT.

CHECK PURGE BLOWER FOR BINDING

OR MECHANICAL DAMAGE.

BREAK & REMAKE THERMOSTAT DEMAND

TO INITIATE CONTROL SEQUENCE.

IS120VAC PRESENT ACROSS PURGE

BLOWER MOTOR TERMINALS?

NO YES

IS 120VAC PRESENT BETWEEN

JP1−6 AND JP1−5?

DOES PURGE BLOWER RUN?

REPLACE

PURGE BLOWER.

REPLACE

PRIMARY CONTROL.

CHECKOUT

WIRING

CONNECTIONS

& REPAIR.

IS GAS VALVE ACTUALLY OPENING?

DETERMINE BY CHECKING FOR MANIFOLD

PRESSURE DURING TRIALS FOR IGNITION.

REPLACE GAS VALVE.

CORRECT

GAS PRES

SURE.

AIR

CHECKS

REMOVE AIR INTAKE CHAMBER COVER

(USE CARE TO PREVENT DAMAGE TO COVER GASKET).

8

9

CHECK GAS SUPPLY LINE PRESSURE

IS PRESSURE WITHIN UNIT NAMEPLATE LISTING?

GAS, AIR and SPARK CHECKS

NOTE− Numbered steps refer to illustrations on page 61.

NOYES

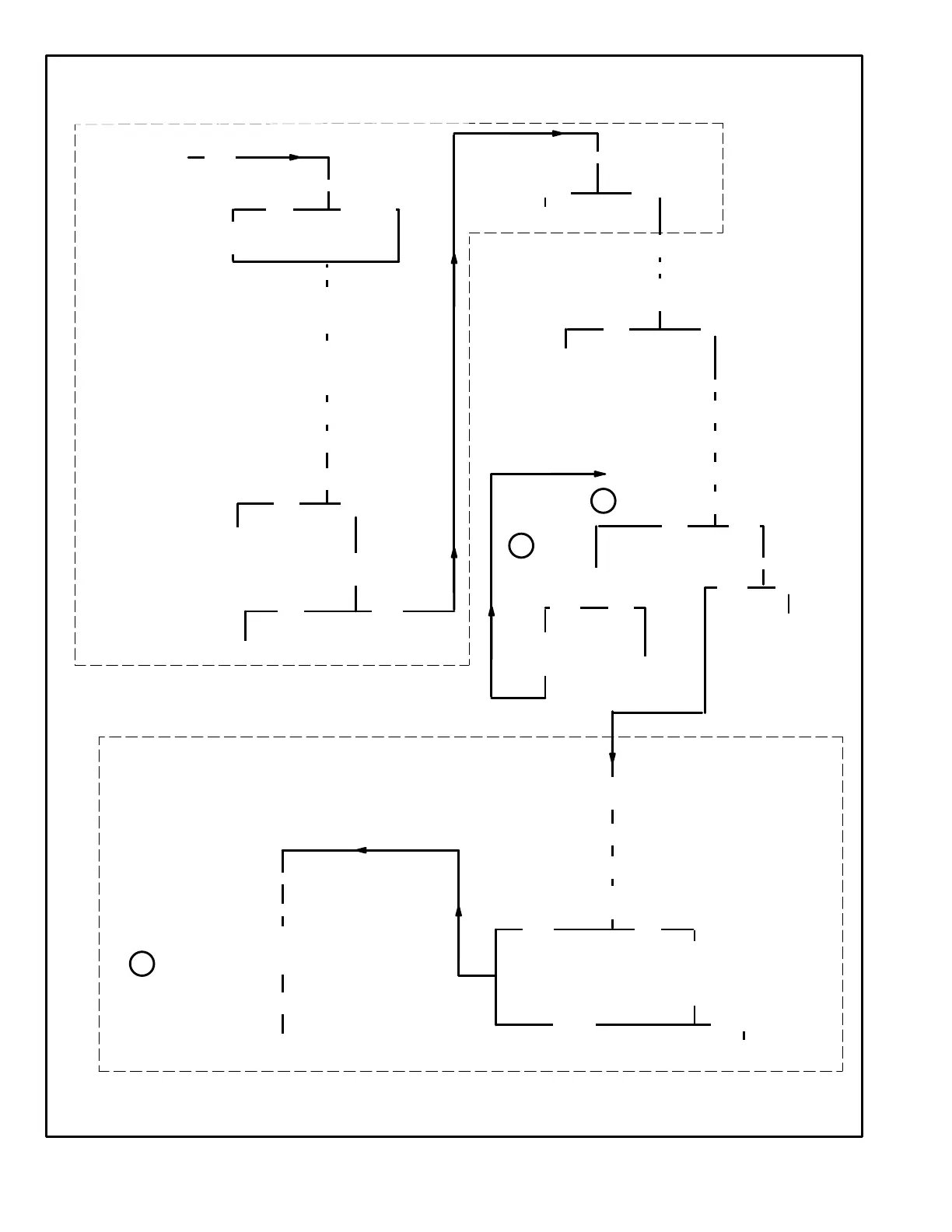

TO CHECK FOR SPARK, USE EXTERNAL PLUG CONNECTED

TO SPARK WIRE. MAKE SURE SPARK GROUND STRAP

IS FIRMLY GROUNDED TO UNIT.

DANGERSHOCK HAZARD. TURN OFF GAS SUPPLY BEFORE TESTING.

DO NOT HANDLE SPARK PLUG OR WIRE DURING TEST.

RESTART IGNITION SEQUENCE

(BREAK & REMAKE THERMOSTAT DEMAND).

AFTER 30 TO 35 SECONDS PRE−PURGE, IS SPARKING PRES

ENT

FOR APPROXIMATELY 7 SECONDS DURING IGNITION TRIAL?

CHECK FOR IGNITION WIRE(FOR BREAKS OR SHORTS TO

GROUND)

& FOR LOOSE CONNECTIONS TO CONTROL AND/OR SPARK PLUG.

MAKE OHMMETER CHECK.

BREAK & REMAKE THERMOSTAT DEMAND

TO INITIATE CONTROL SEQUENCE.

REPLACE

PRIMARY CONTROL.

NO SPARKSPARK

REPLACE AIR INTAKE CHAMBER COVER. TURN ON GAS & RESTART UNIT.

PUT PLUG BACK IN UNIT. TURN ON POWER.

(LEAVE GAS OFF) & RETEST FOR SPARK.

4. REPLACE AND/OR REGAP PLUG IF REQUIRED.

3. IS PLUG GAPPED PROPERLY?

2. ARE CRACKS PRESENT IN PORCELAIN?

1. WAS PLUG TIGHT WHEN REMOVED?

REMOVE & CHECK SPARK PLUG (USE 3/4" SPARK PLUG SOCKET).

TURN OFF POWER.

SPARK CHECKS

CAUTIONHIGH VOLTAGE

10

Loading...

Loading...