Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05 155

8 Diagnostics & error management

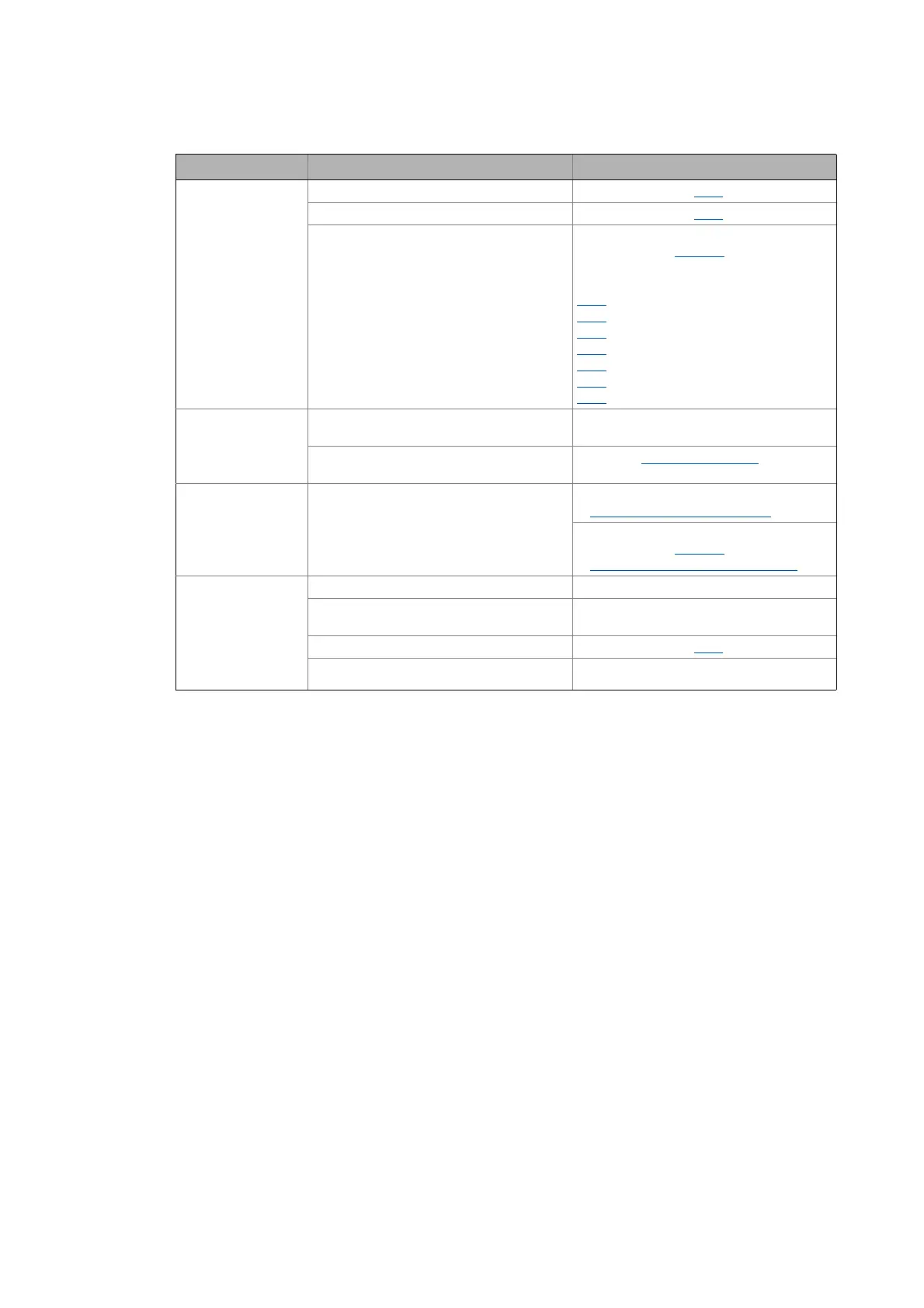

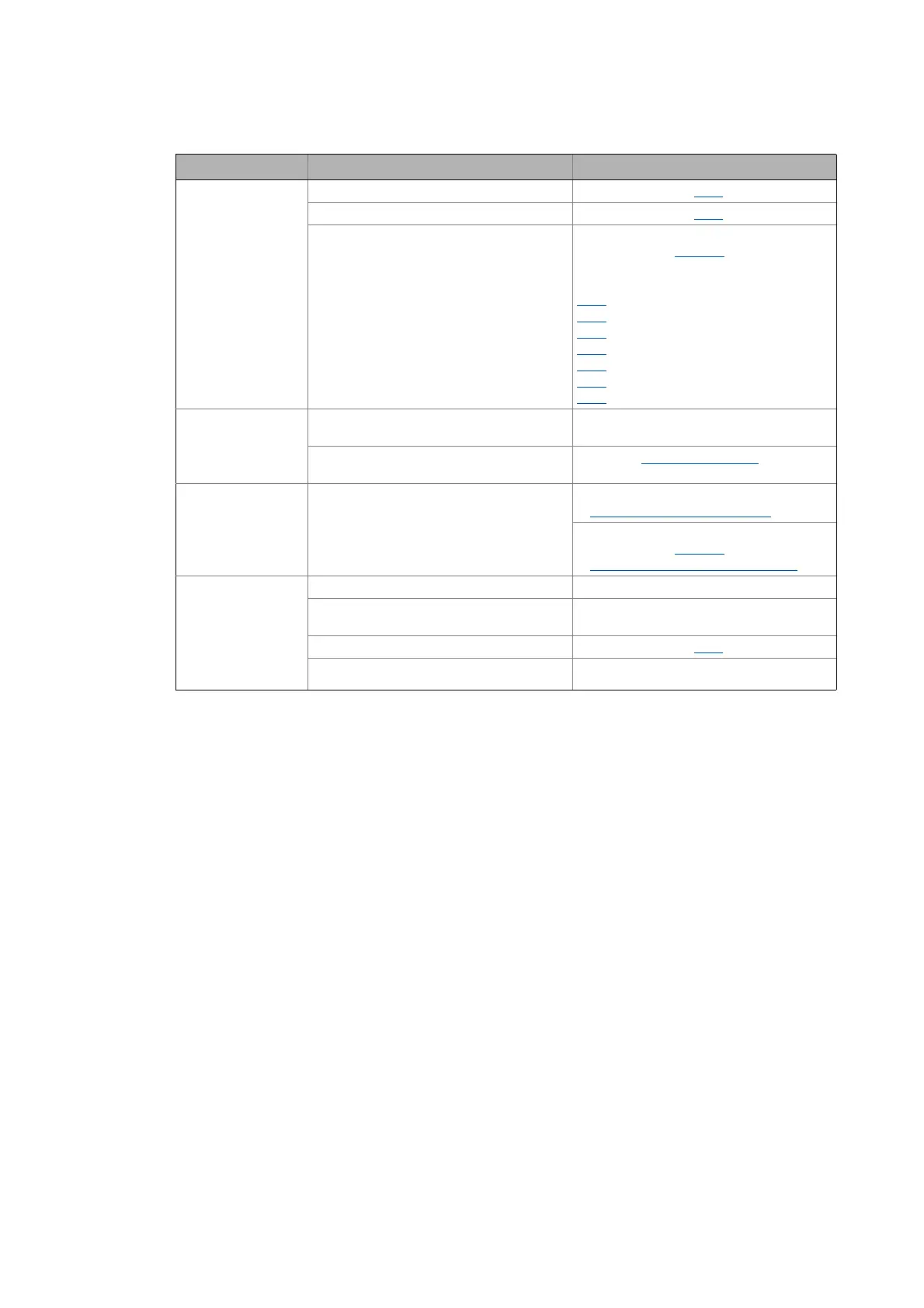

8.6 Maloperation of the drive

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

Motor consumes too

much current

U

min

boost has been selected too high Correct setting with C016

V/f base frequency has been selected too low Correct setting with C015

Rated motor data (stator resistance, speed,

current, frequency, voltage) and cos ϕ and/

or magnetising inductance is not adapted to

the motor data

Carry out automatic motor parameter identi-

fication with the C002/23

device command

- or -

Adjust motor parameters manually:

C084

: Motor stator resistance

C087

: Rated motor speed

C088

: Rated motor current

C089

: Rated motor frequency

C090

: Rated motor voltage

C091

: Motor cosine phi

C092

: Motor magnetising inductance

Motor parameter

identification is abor-

ted with error LP1

Motor is too small compared to the rated de-

vice power (>1 : 3)

Use device with lower rated power

DC injection braking (DCB) is active via termi-

nal

Deactivate DC-injection braking

Drive behaviour with

vector control is not

satisfactory

different Optimise or manually adapt vector control

Sensorless vector control (SLVC)

Carry out automatic motor parameter identi-

fication with the C002/23

device command

Automatic motor data identification

Torque dip in field

weakening range

or

motor stalling when

being operated in the

field weakening ran-

ge

Motor is overloaded Check motor load

Motor windings are wired incorrectly Reverse from star connection to delta con-

nection

V/f base frequency is set too high Correct setting with C015

Mains voltage is too low Increase mains voltage

Maloperation Cause Remedy

Loading...

Loading...