5 Motor control (MCTRL)

5.1 Motor selection/Motor data

70

Lenze · 8400 BaseLine C · Reference manual · DMS 1.6 EN · 01/2014 · TD05

_ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _ _

5.1.2 Automatic motor data identification

Via the "Identify motor parameters" device command " (C002/23), the inverter characteristic, the in-

fluences of the motor cable, and the motor parameters listed in the table below can be identified

automatically:

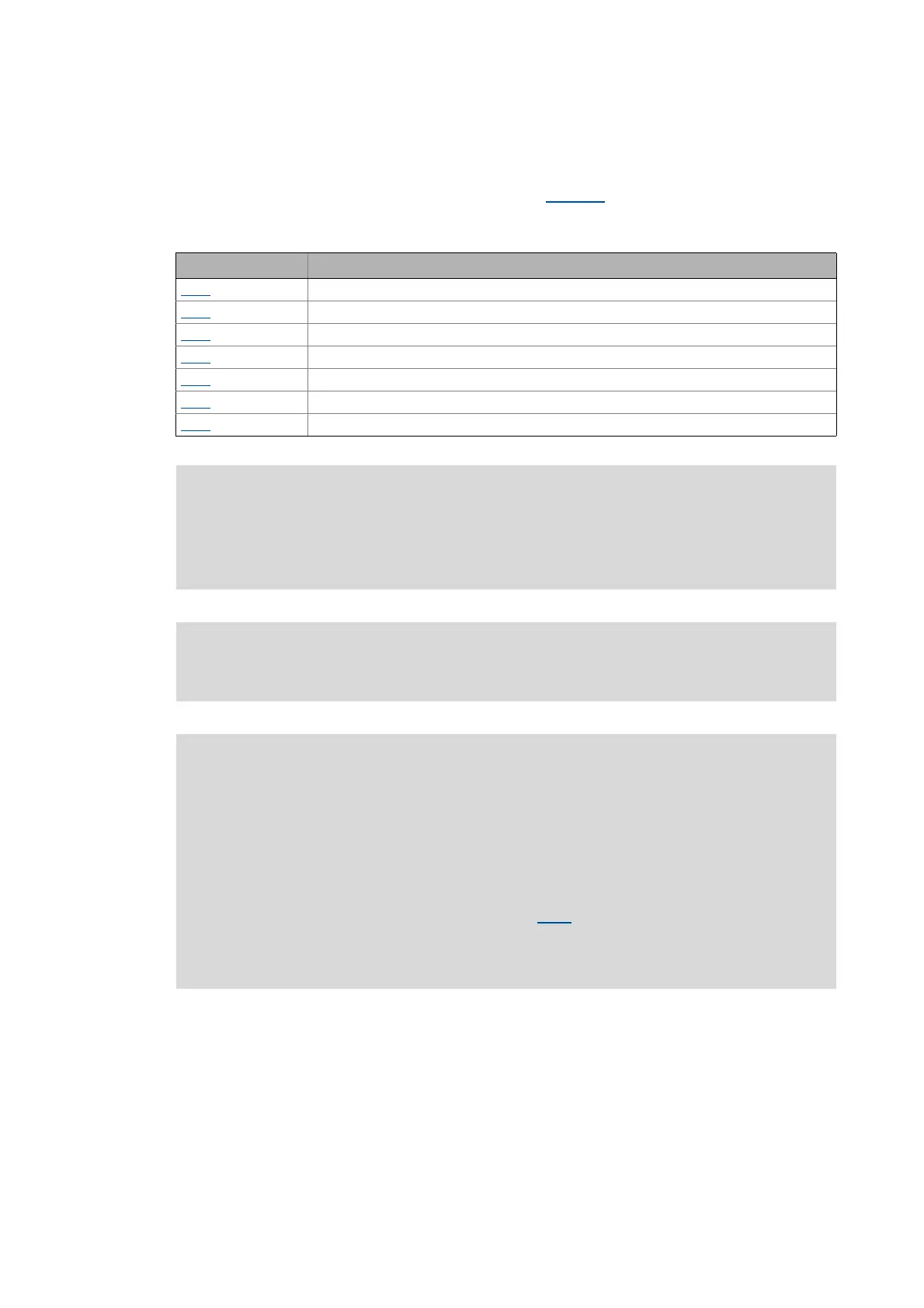

Parameter Info

C015

V/f base frequency

C016

V

min

boost

C021

Slip compensation

C084

Motor stator resistance

C085

Motor stator leakage inductance

C092

Motor magnetising inductance

C095 Motor magnetising current

Danger!

During motor parameter identification, the motor is energised via the outputs U, V and

W of the controller!

Observe the corresponding safety instructions!

Stop!

If motor parameter identification is aborted, unstable drive behaviour may be the result!

Note!

• We strongly recommend motor parameter identification before the initial commis-

sioning of the sensorless vector control (SLVC).

• The motor parameter identification must be carried out when the motor is cold!

• The load machine may remain connected. Holding brakes, if present, may remain in

the braking position.

• With an idling motor, a small angular offset may occur at the motor shaft.

• The amplitude of the rated motor current (C088

) is injected to identify the stator re-

sistance. If the rated motor current amounts to less than 60 % of the rated inverter

current, at least 60 % of the rated inverter current will be injected to ensure sufficient

motor parameter identification accuracy.

Loading...

Loading...