Basic units in the power range 3 ... 11 kW

Mounting in ”cold plate” technique

5

Basic device installation

5.4

5.4.3

L

5.4-4

EDS82EV903-1.0-11/2002

5.4.3 Mounting in ”cold plate” technique

When using ”cold plate” technique the controllers can be mounted to sum

coolers. Use controllers of type E82CV... .

The following points are important to ensure a safe operation of the drive

controllers:

l Good thermal contact with the cooler:

– The contact area between the cooler and the drive controller must be at

least as large as the cooling plate of the drive controller.

– Plane contact area, deviation max. to 0.05 mm.

– The cooler and heatsink must be attached using all the screwed joints

that are specified.

l Thermal resistance R

th

according to table. The values are valid for operation

with the drive controllers under rated conditions.

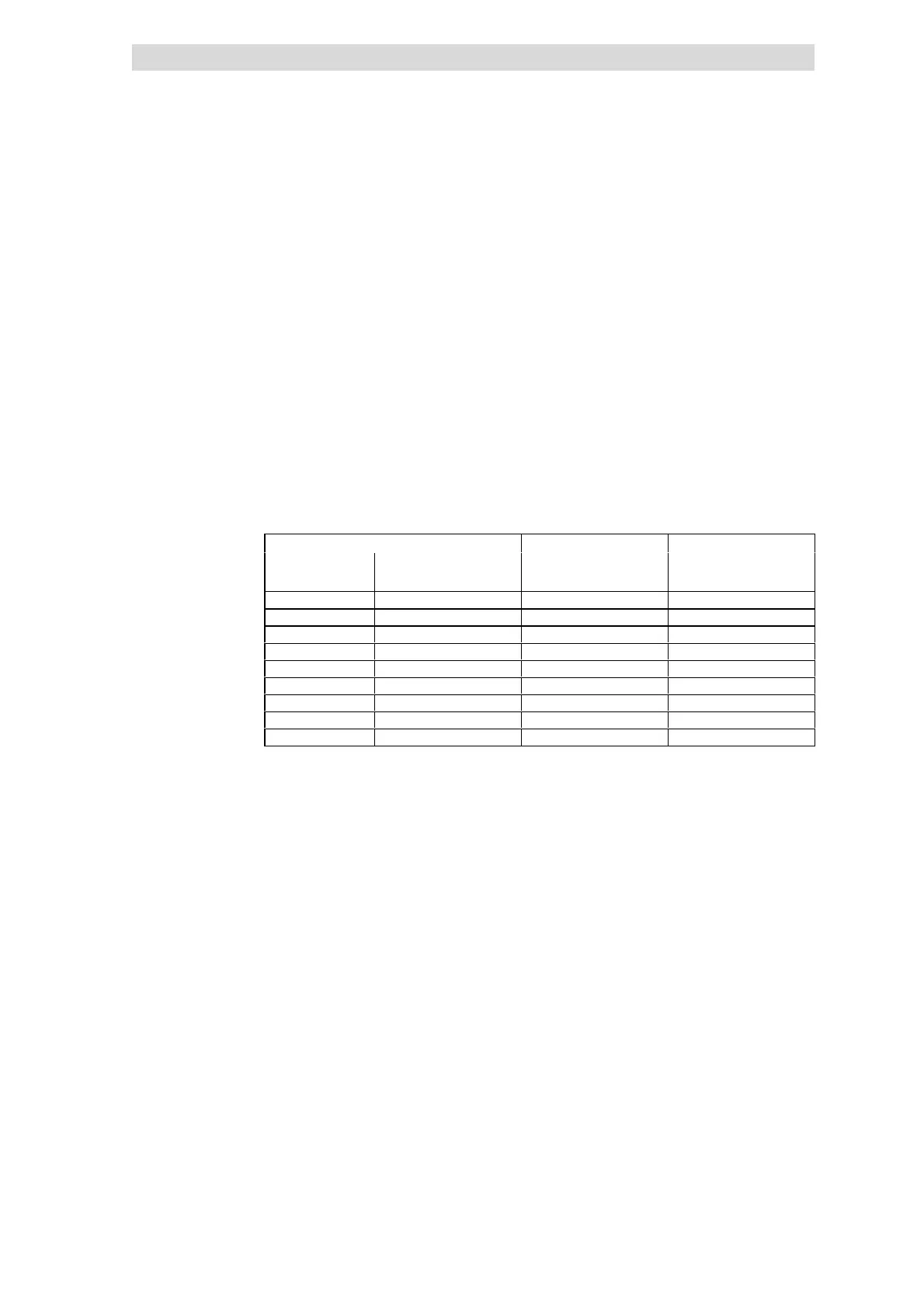

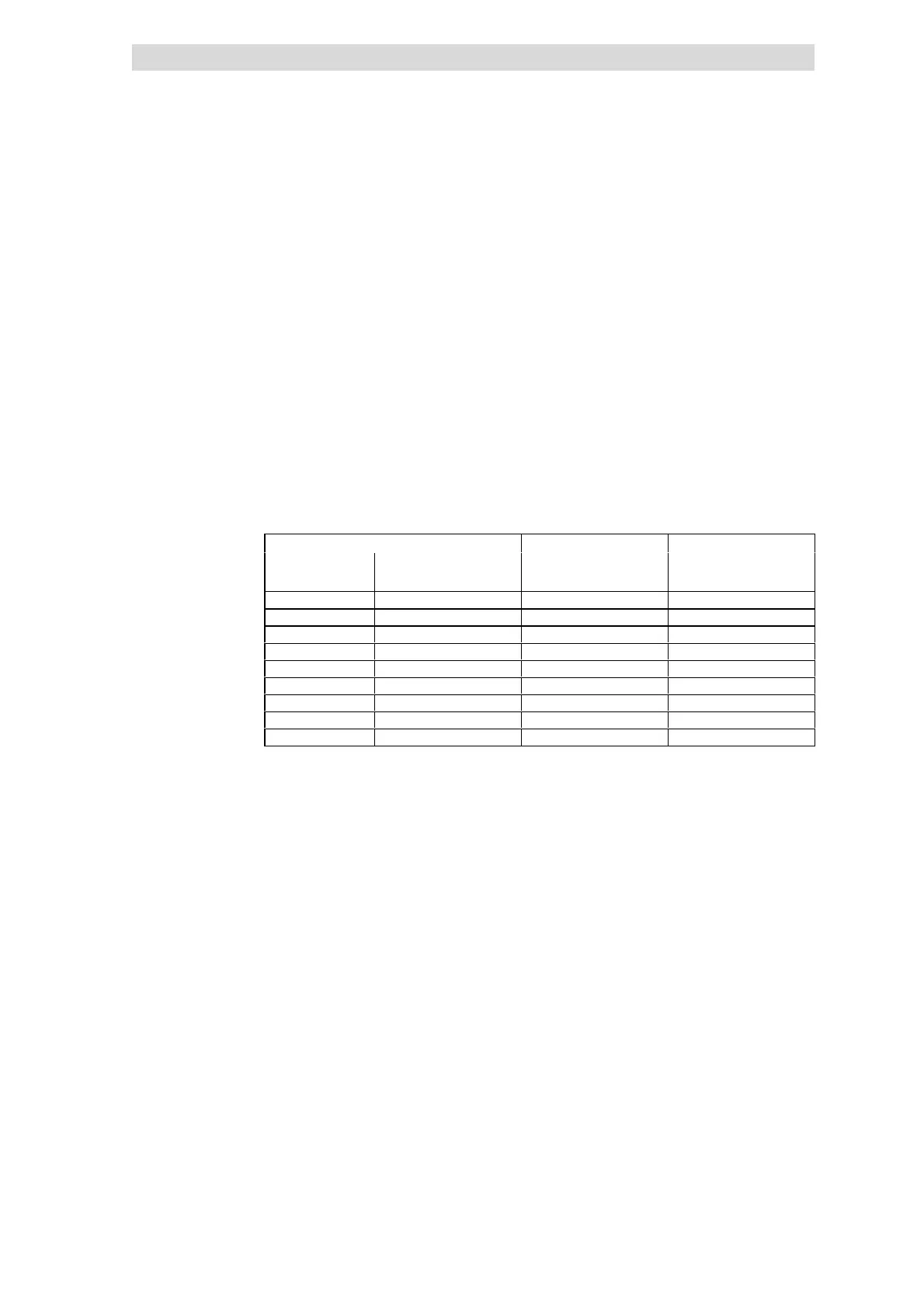

8200 vector Cooling p ath Ground

Power to be dissipated Heatsink - environment

Type P

loss

[W] R

th

[°C/W] [kg]

E82CV302K2C 110 ≤ 0.23 2.4

E82CV402K2C 150 ≤ 0.23 2.4

E82CV552K2C 205 ≤ 0.13 3

E82CV752K2C 270 ≤ 0.13 3

E82CV302K4C 110 ≤ 0.23 2.4

E82CV402K4C 140 ≤ 0.23 2.4

E82CV552K4C 190 ≤ 0.23 3

E82CV752K4C 255 ≤ 0.13 3

E82CV113K4C 360 ≤ 0.13 3

l Ambient temperature - controllers

– The rated data and the derating for higher temperatures still apply for the

ambient temperature of the drive controller.

l Heat distribution between common heatsinks/coolers within the control

cabinet

– If you mount several components (drive controller, brake units etc.) on a

common cooler, then care must be taken that the temperature of the

controller heatsinks does not exceed 75 °C.

Requirements on the cooler

Environmental conditions

Loading...

Loading...