19

COMPILER TECO/ATL

REG. CODE

1-5302-296

MODEL N°

50510

DATE OF ISSUE

01.89

REVISION 02

ENDORSED

DATE

17.04.2003

VIII

1

2

3

DISASSEMBILY AND REASSEMBLY

Besides disassembly and reassembiy operations this chapter also

includes checking and setting specifications, dimensions, repair

and operating instructions. Always use original LOMBARDINI spare

parts for proper repair operations.

Do not blow the paper filter element with compressed air to

clean.

Check gaskets and replace as necessary. Check that flange

welds are free of defective spots.

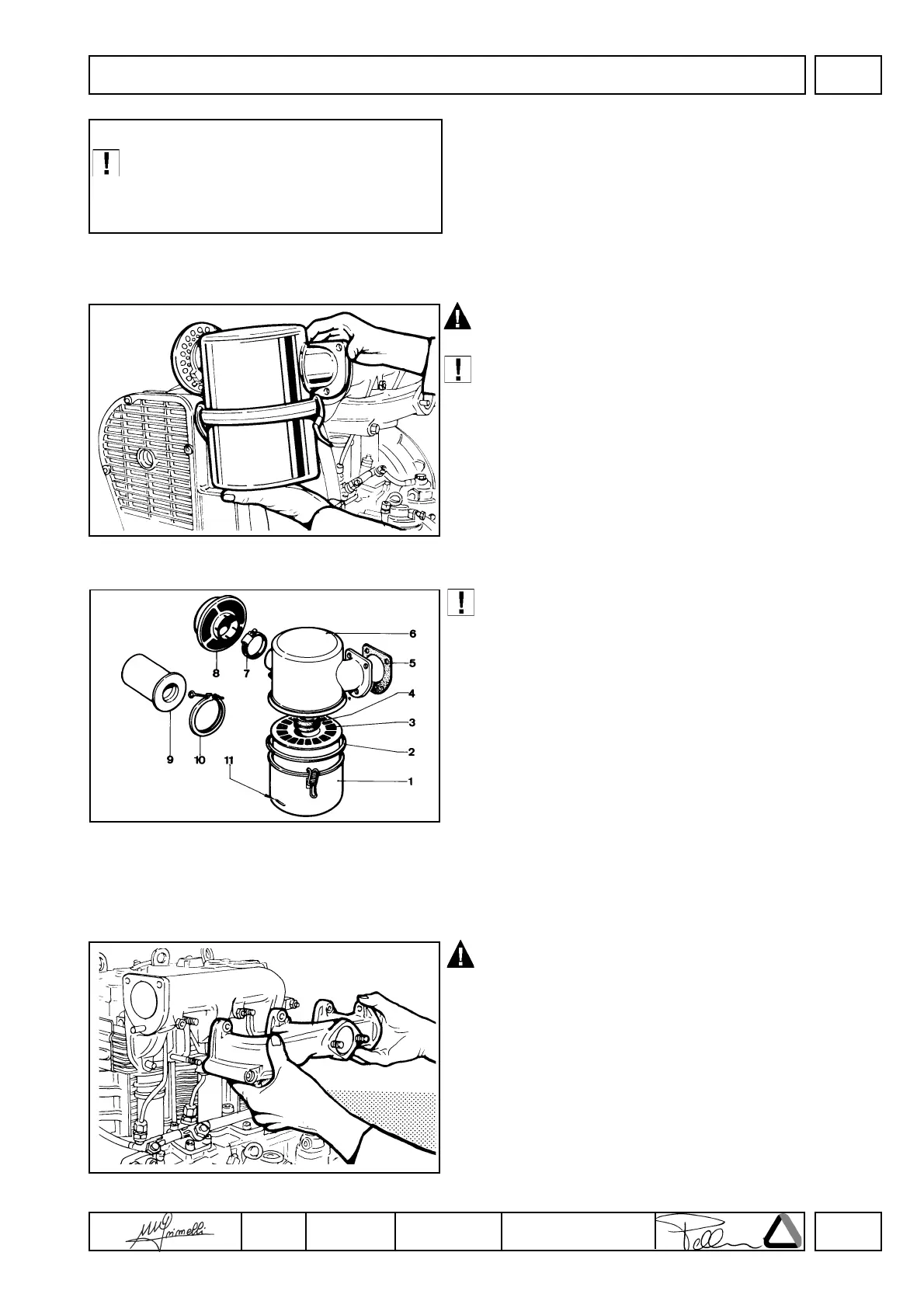

Aír cleaner

Carefully clean bowl and filtering elements with DieseL fuel and

blow through with compressed air. Top up with engine oil to the

mark. When refitting tighten nuts at 2.5 Kgm. See Page 16-17 for

periodic maintenance detaiis.

Replace if irreparably clogged.

Air cleaner components

1 Bowl

2 External seal ring

3 Filtering element

4 Internal seal ring

5 Gasket

6 Cover

7 Cover clamp

8 Cap

9 Centrifugal pre-filter

10 Centrifugal pre-filter clamp

11 Oil level mark

Note: It is inadvisable to blow compressed air on to the paper filter

element. If necessary, lightly and repeatedly tap the element on a

hard surface to eliminate any excess dirt. See page 16-17 for the

maintenance or replacement instructions.

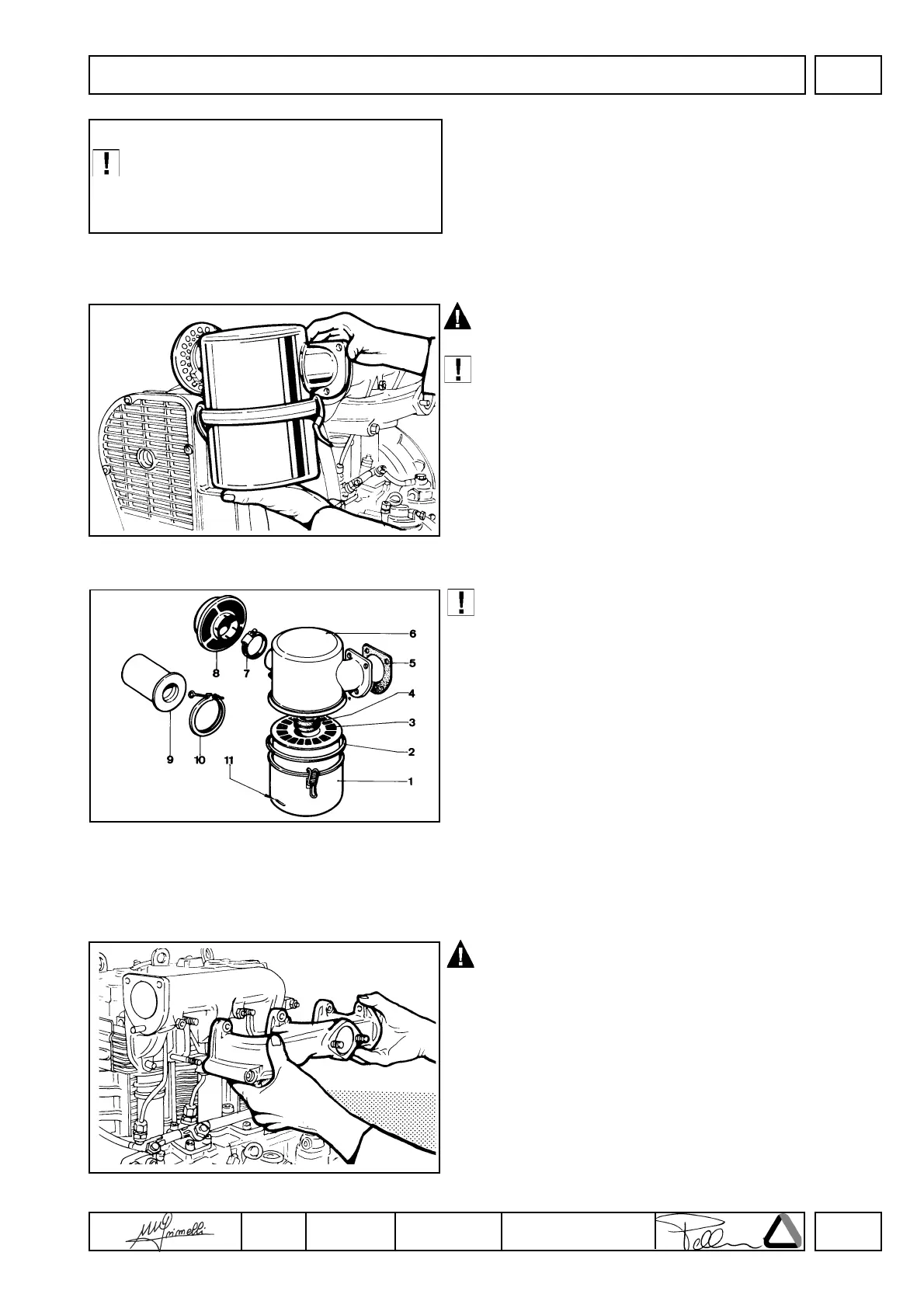

Allow the exhaust manifold to cool before demounting it in

order to prevent scorching and burns.

Exhaust manifold

Check that the inside is clean. To avoid flange breakage check that

heads are in line before tightening nuts. Replace gaskets. Tighten

nuts at 2 Kgm.

During repair operations, when

using compressed air, wear eye

protection.

DISASSEMBLY/REASSEMBLY

Loading...

Loading...