55

COMPILER TECO/ATL

REG. CODE

1-5302-296

MODEL N°

50510

DATE OF ISSUE

01.89

REVISION 02

ENDORSED

DATE

17.04.2003

144

143

142

X

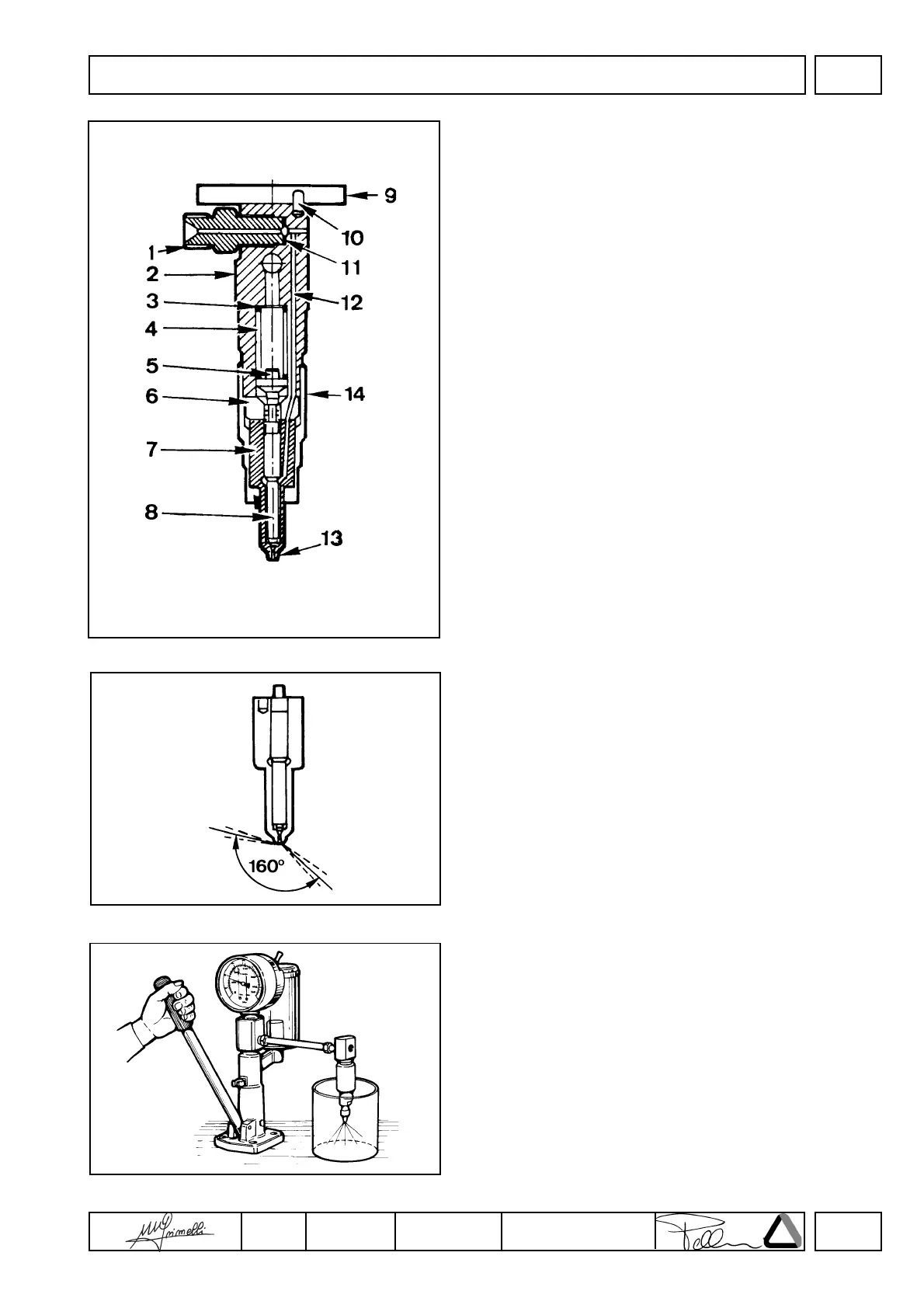

INJECTOR

Components:

1 Intake fitting

2 Nozzle holder

3 Shim

4 Spring

5 Pressure rod

6 Intermediate flange

7 Nozzle

8 Needle valve

9 Fixing flange

10 Taper pin

11 Gasket

12 System duct

13 Sump

14 Cup

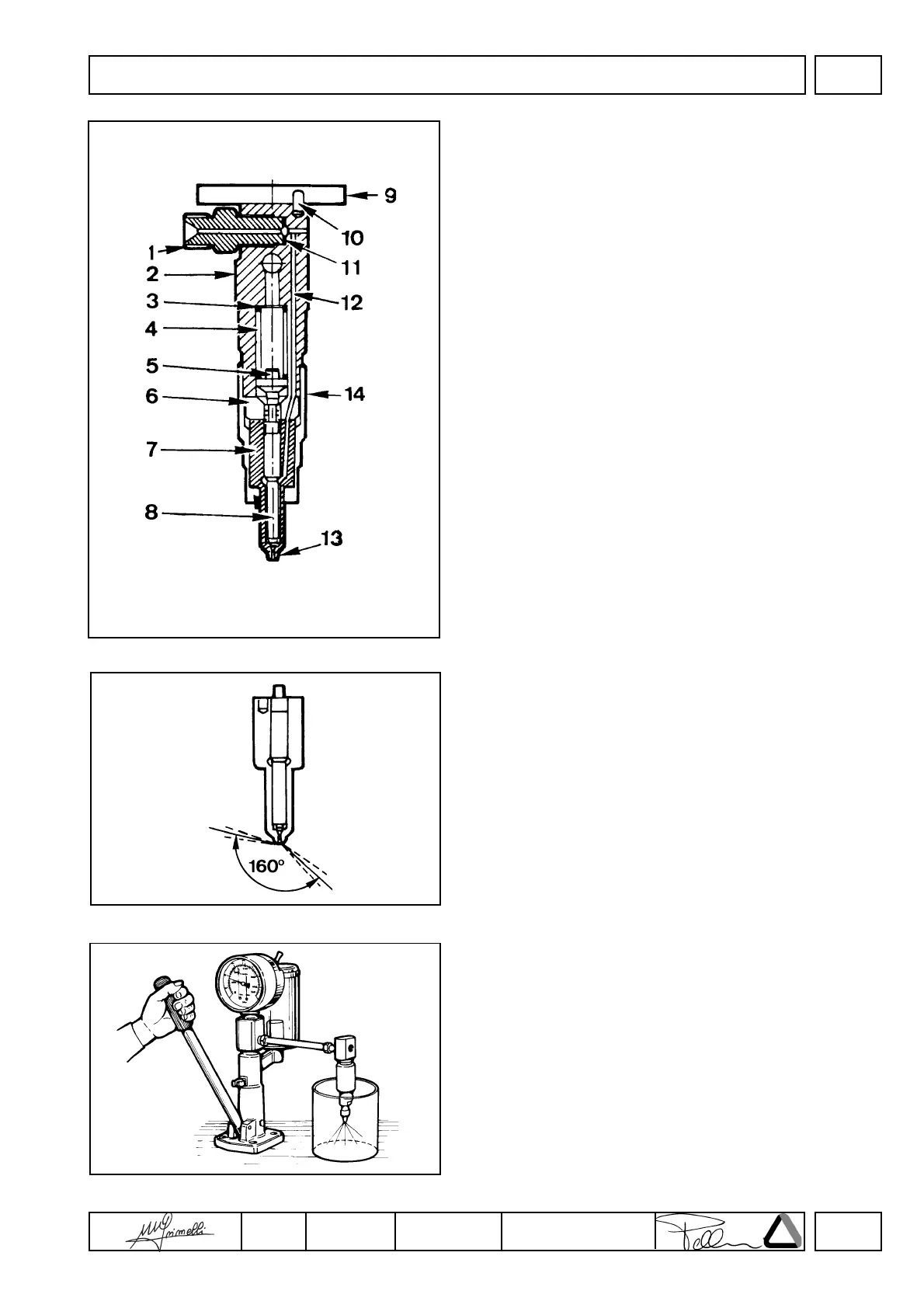

Nozzle

Features:

Hole number and diameter 4x0.28 mm.

Jet angles = 160°.

Needle valve elevation = 0.20÷0.22 mm

Hole length = 0.7 mm

Sump diameter and length = 1x1.5 mm

Clean nozzle tip with a brass brush.

Check that holes are not obstructed using a mandrel with steel wìre

with 0.28 mm diam.

When refitting tighten ring nut at 7 Kgm.

Injector setting

Connect injector to a hand pump and check that setting pressure is

210÷220 bar; make the required adjustments, if any, by changing

the shim over the spring.

When replacing the spring, setting should be performed at a 10 bar

greater pressure (220÷230 bar) to allow for bedding during

operation. Check needIe valve sealing by slowly moving hand pump

until approximately 180 bar.

Replace nozzle in case of dripping.

FUEL SYSTEM

Loading...

Loading...