STRUCTURAL CD3340B/YB4411

11-44

Published 04/07/2015 Control # 569-00

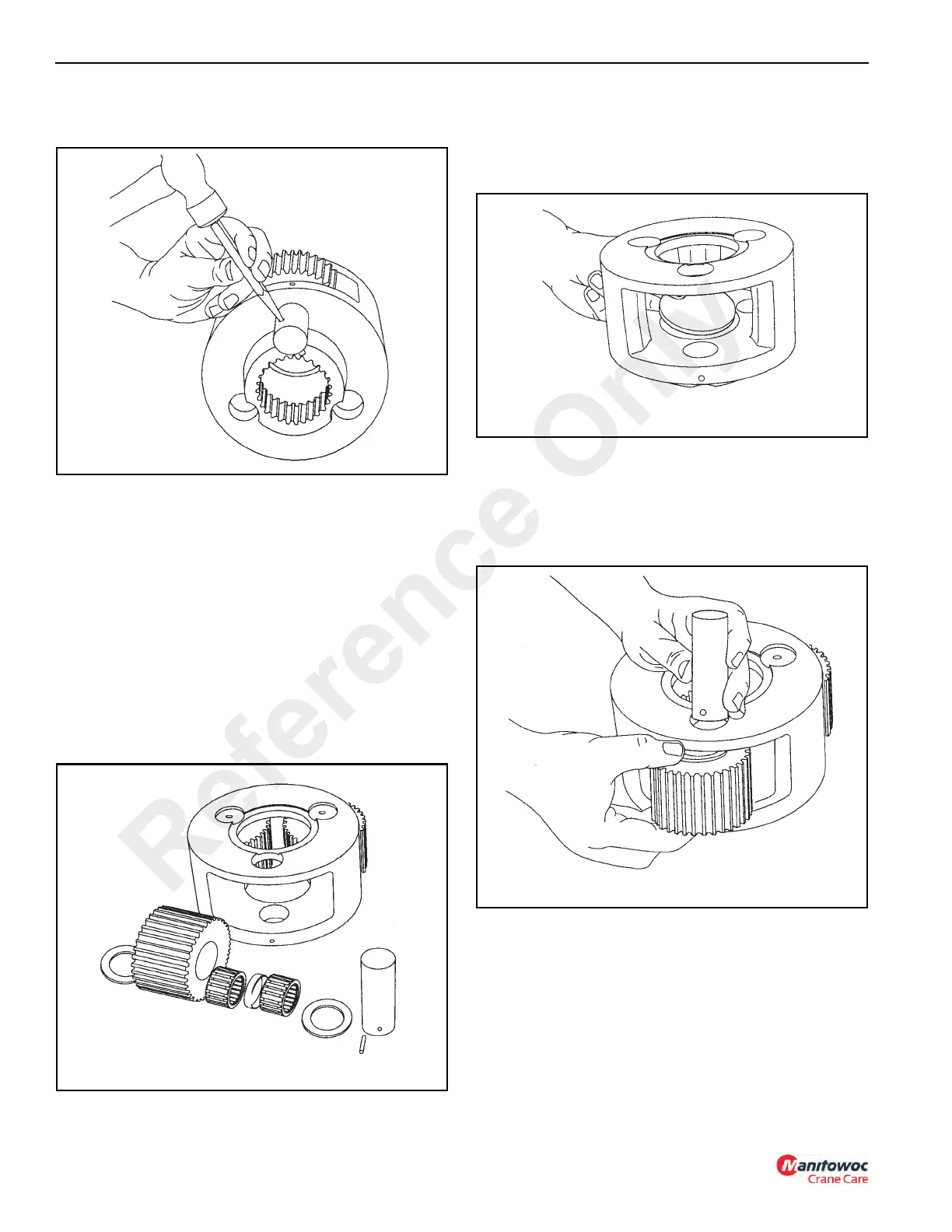

2. Use a punch (Figure 11-100) to drive the roll pins from

the planet shafts. Do not reuse the roll pins.

3. Now you can remove the planet shafts, bearings,

spacer, thrust washers and gears. Thoroughly clean all

parts and inspect for damage and wear. The bearing

rollers should not exhibit any irregularities. If the rollers

show any sign of spalling, corrosion, discoloration,

material displacement or abnormal wear, the bearing

should be replaced. Likewise, the cage should be

inspected for unusual wear or deformation, particularly

the cage bars. If there is any damage that will impair the

cage’s ability to separate, retain and guide the rollers

properly, the bearing should be replaced. The thrust

washer contact areas should be free from any surface

irregularities that may cause abrasions or friction. The

gears and shafts should be inspected for abnormal wear

or pitting. Replace if necessary.

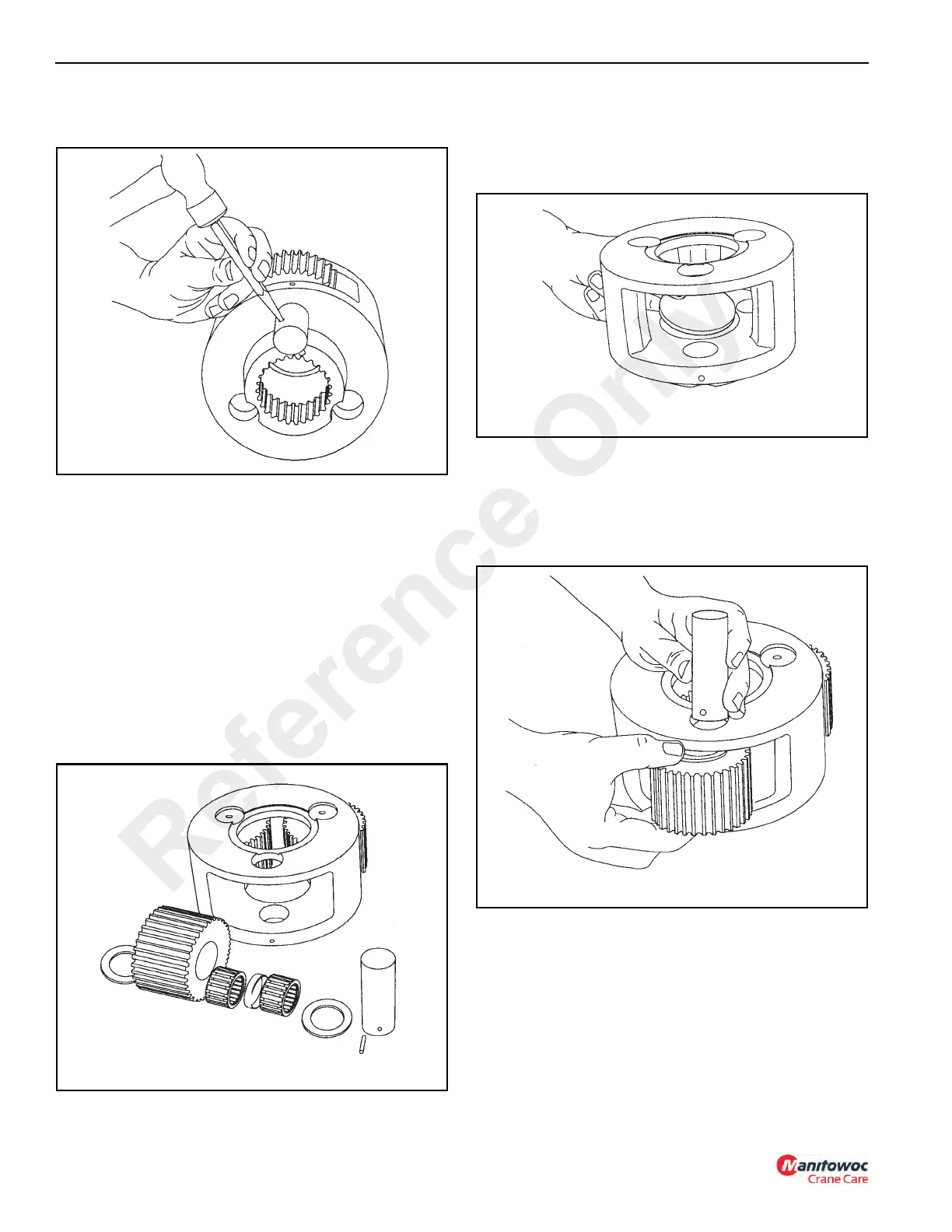

Assembly

1. Place the output planet carrier on workbench with spline

coupling side down. Install output thrust plate in center

of carrier (Figure 11-102).

2. Insert two (2) bearings and a bearing spacer into a gear

with the spacer between the bearings. Place a thrust

washer on each side of the gear and position in a carrier

opening. Slide the shaft through the carrier, thrust

washer, bearing-gear subassembly and remaining thrust

washer (Figure 11-103).

3. Carefully align the pin hole in the carrier with the hole in

the planet gear shaft (Figure 11-104) and drive the roll

pin into place. Always use NEW roll pins. When properly

positioned, 50% of the roll pin will engage the planet

gear shaft and 50% will remain in the planet carrier.

Reference Only

Loading...

Loading...