8-14 Published 11-22-2016, Control # 345-12

UNDERCARRIAGE RT9130E-2 SERVICE MANUAL

Bleeding the Brake System

The brake system should be bled whenever air becomes

entrapped within the brake system (usually characterized by

a spongy feeling during brake pedal application), whenever

any brake system line has been opened, or whenever any

brake component has been replaced.

Always start at the point in the system that is furthest from

the tandem brake valve and work back toward the tandem

brake valve. Bleed every bleeder screw on every caliper/

actuator on every wheel. When you complete a bleeder

screw, go to the next closest bleeder screw on the same

caliper/actuator. When you complete a wheel, go to the

furthest bleeder screw on the next closest wheel.

Service Brakes

Description

The brakes utilized are hydraulic disc-type brakes. Two

brake assemblies are used at the end of each axle. The

action of the brake pads riding against the brake discs acts to

slow the rotation of the wheels.

Maintenance

NOTE: To perform maintenance on the brake caliper,

remove the tire and wheel assembly. Refer to

Axles, page 8-1.

Removal

Linings

1. Remove the bolts securing the end plates to one side of

the caliper housing. Remove the end plates.

2. Loosen the bleeder screws to release hydraulic

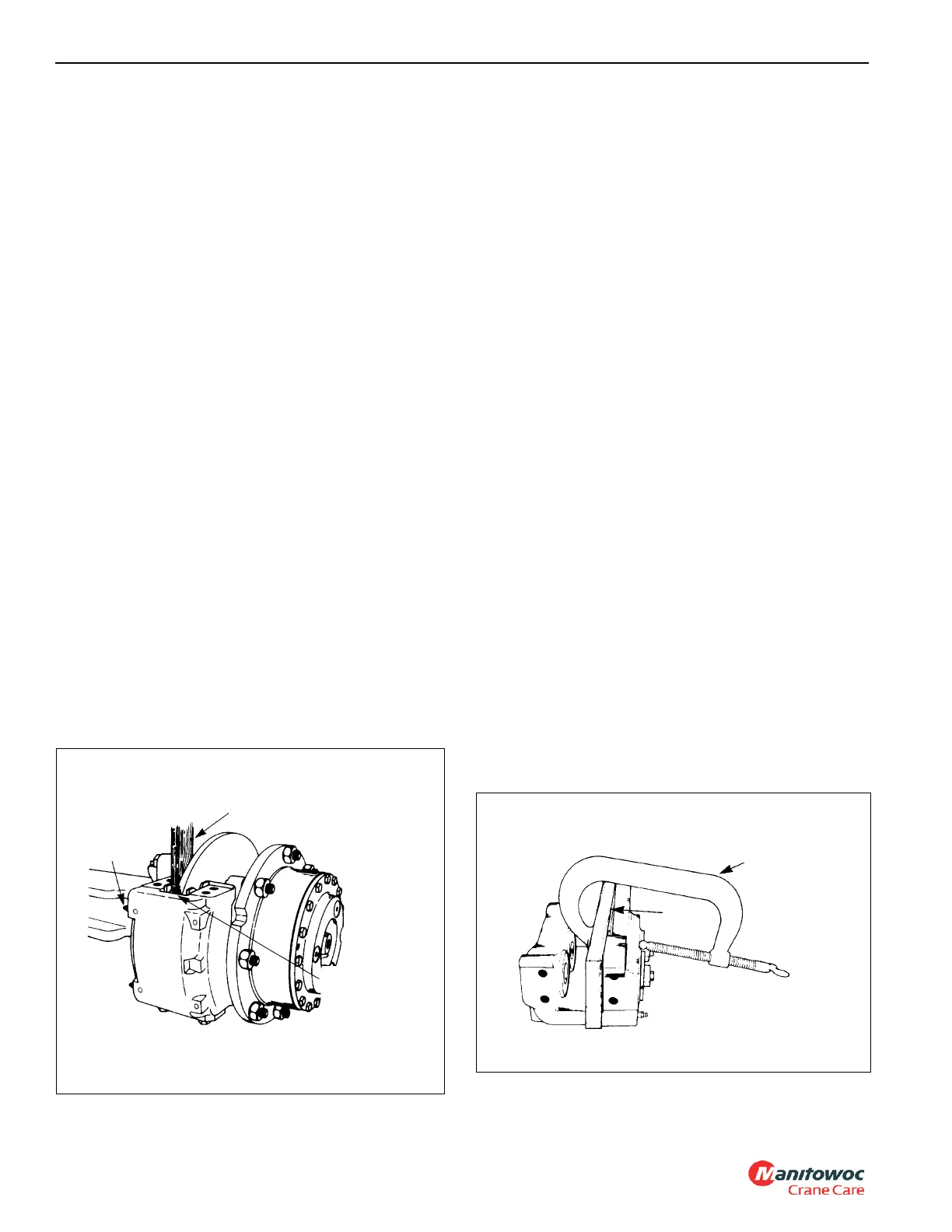

pressure in the caliper (Figure 8-5).

3. Use a piece of wood against the linings as a pry bar to

push the pistons completely into the housing. Tighten

the bleeder screws.

4. Remove the linings from the caliper housing. If

necessary, discard the linings.

Caliper

NOTE: To lighten caliper weight, remove the brake linings

from the caliper before removing the caliper from

the vehicle.

1. Disconnect the hydraulic brake line from the inlet fitting

on the caliper. Cap or plug all openings.

2. Remove the linings as described previously.

3. Remove the bolts securing the caliper housing to the

mounting bracket. Remove the caliper housing from the

mounting bracket. If shims are used mark the position of

the shims.

Disassembly

Caliper

1. Remove the inlet fitting and o-ring from the cylinder cap.

2. Drain and discard the hydraulic fluid.

3. Clean the outside of the housing with isopropyl alcohol.

Dry the housing with a clean cloth.

4. If installed, remove the bolts that secure the end plates

to the housing. Remove the end plates and linings.

5. Remove the pistons from the side of the housing

opposite the mounting plate according to the following

procedure.

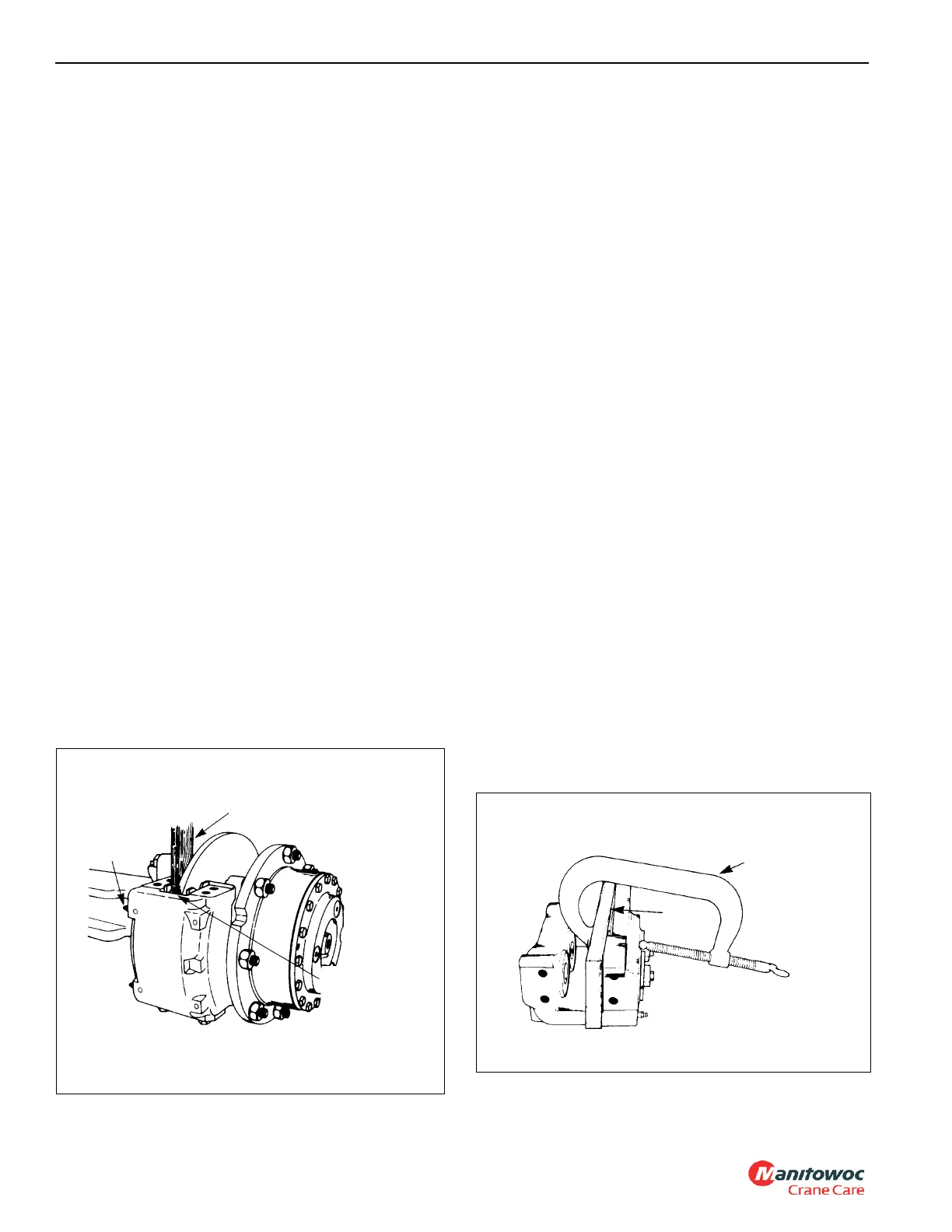

a. Use a C-clamp to hold a 0.5 in (12.7 mm) block of

wood against three pistons on the mounting side of

the housing. Ensure the C-clamp is not in the area in

front of the piston bore (Figure 8-6).

FIGURE 8-5

Wood Block

Loosen

Bleeder

Screws

Push wood

block against

linings to push

pistons into

bores

Wood

Block

C-Clamp

FIGURE 8-6

Loading...

Loading...