Grove Published 11-22-2016, Control # 345-12 2-49

RT9130E-2 SERVICE MANUAL HYDRAULIC SYSTEM

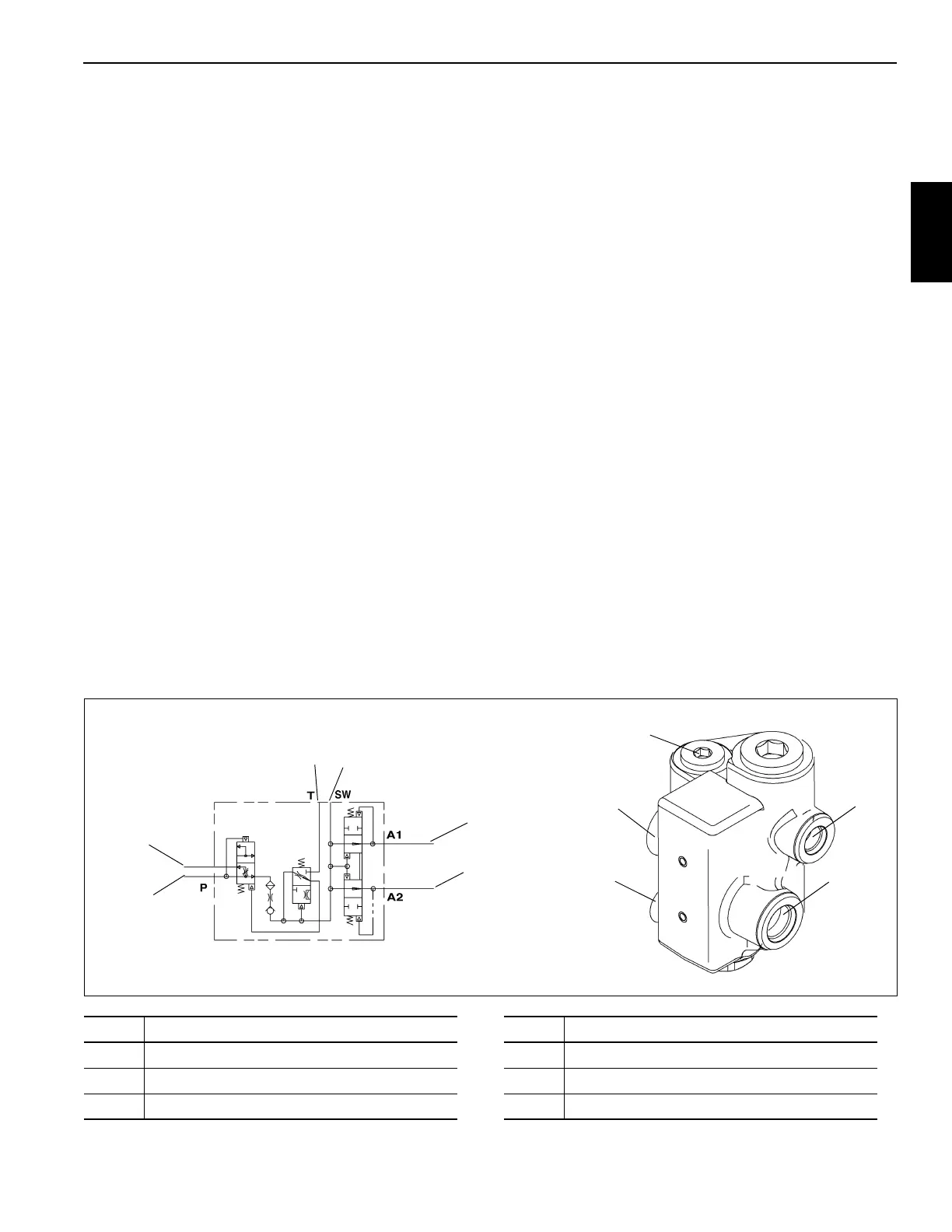

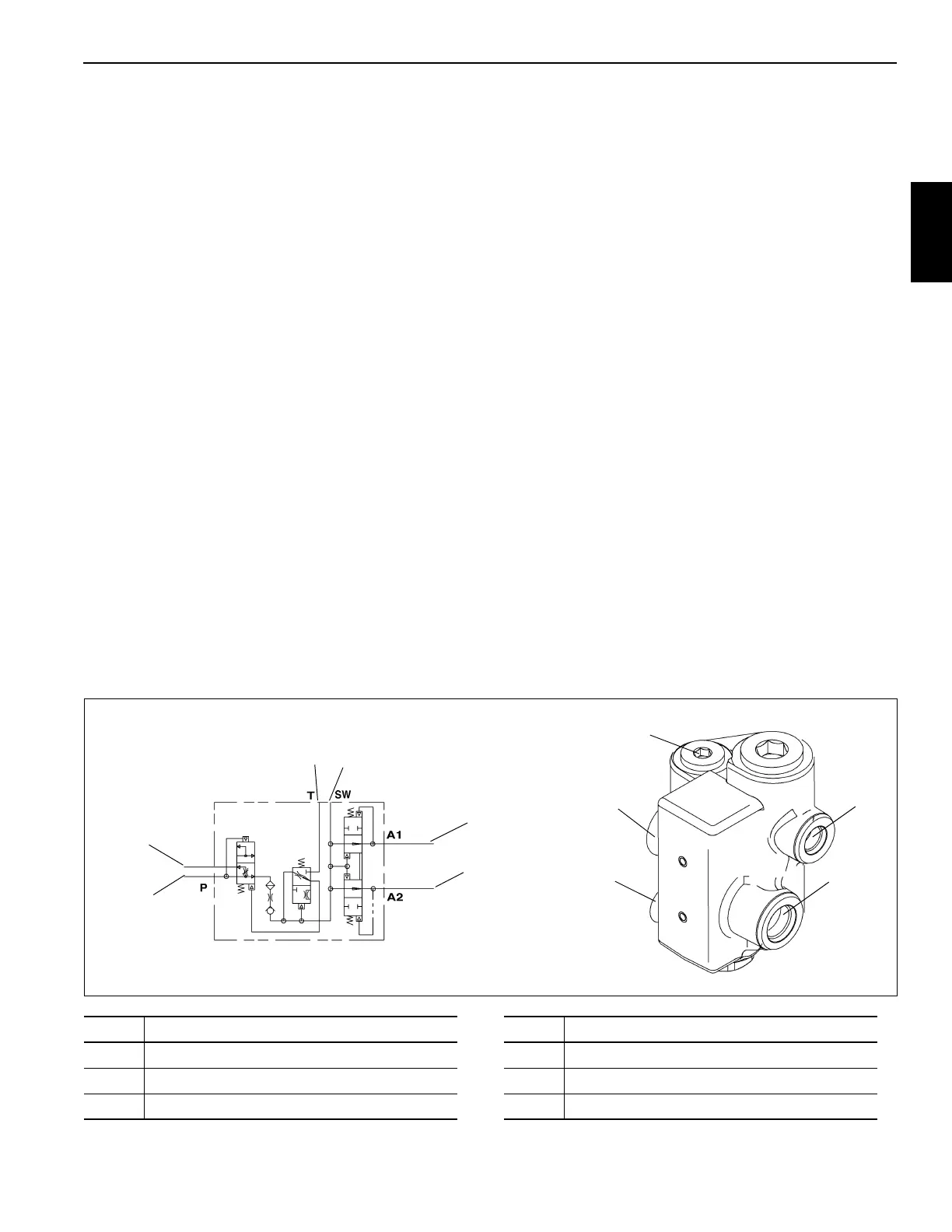

DUAL ACCUMULATOR CHARGE VALVE

Description

The dual accumulator charge valve Figure 2-29 is located on

the turntable left side, inside the superstructure. The purpose

of the valve is to provide a priority regulated flow dependent

on the maximum pressure required to the service brake

circuit and a secondary source of flow for the front steer and

swing circuits. The dual accumulator charge valve regulates

flow to the hydraulic accumulators at a rate of 2.2 to 3.2 gpm

(8.3 to 12.1 l/min) to provide stored energy for the primary

(front) and the secondary (rear) service brake circuits.

The dual accumulator charge valve consists of a charging

section with a proportional flow divided spool and a main

check valve, a control section with a pilot spool with a low

limit check ball and a high limit check ball, and an inverted

shuttle cartridge.

When the valve is charging the accumulators, the

proportional flow divider spool, in the charging section, is in

neutral to allow the charging flow to pass through the main

check valve and on to the pilot control section and the

inverted shuttle cartridge. The pilot control section controls

the opening and closing of the low and high limit check balls.

The pilot spool permits only one of these balls to be open at

any one time. When the low limit check ball is open, the

pressure from the accumulators is applied to shift the

charging section flow divider spool and allow pump flow to

the inverted shuttle cartridge which is normally open to

charge the accumulators.

When the accumulators are charged to the high limit

pressure of 2750 psi (19,000 kPa), pilot pressure will open

the high limit check ball and close the low limit check ball.

The inverted shuttle senses the pressure in the

accumulators and the brake circuits to pilot close the

cartridge when the maximum pressure is reached. After the

accumulators are fully charged, the high limit check ball

opens and the proportional flow divider spool is fully opened

to direct all of the pump flow to the excess flow port and on to

the air conditioning circuits.

Maintenance

Removal

1. Tag and disconnect the hydraulic hoses from the valve.

Cap or plug the lines and ports.

2. Remove the capscrews, flatwashers and lockwashers

securing the valve to the turntable. Remove the valve.

Installation

1. Position the valve on the turntable and secure with the

capscrews, washers and lockwashers.

2. Connect the hydraulic hoses to the valve ports as tagged

during removal.

3. Start the engine and check for leaks. Make repairs as

needed.

4. Depress the brake pedal several times, make several

turns with the steering wheel, and swing the

superstructure left and right. Verify the brakes, swing,

and front steering work properly.

FIGURE 2-29

6436

1

1

2

2

3

3

4

4

5

5, 6

6

Item Description

1 Pressure port

2Switch Port

3Flow Thru Port

Item Description

4 Tank Port

5 Port A1 - To Accumulator

6 Port A2 - To Accumulator

Loading...

Loading...