DIRECT FUEL INJECTION

90-855347R1 JANUARY 1999 Page 3B-37

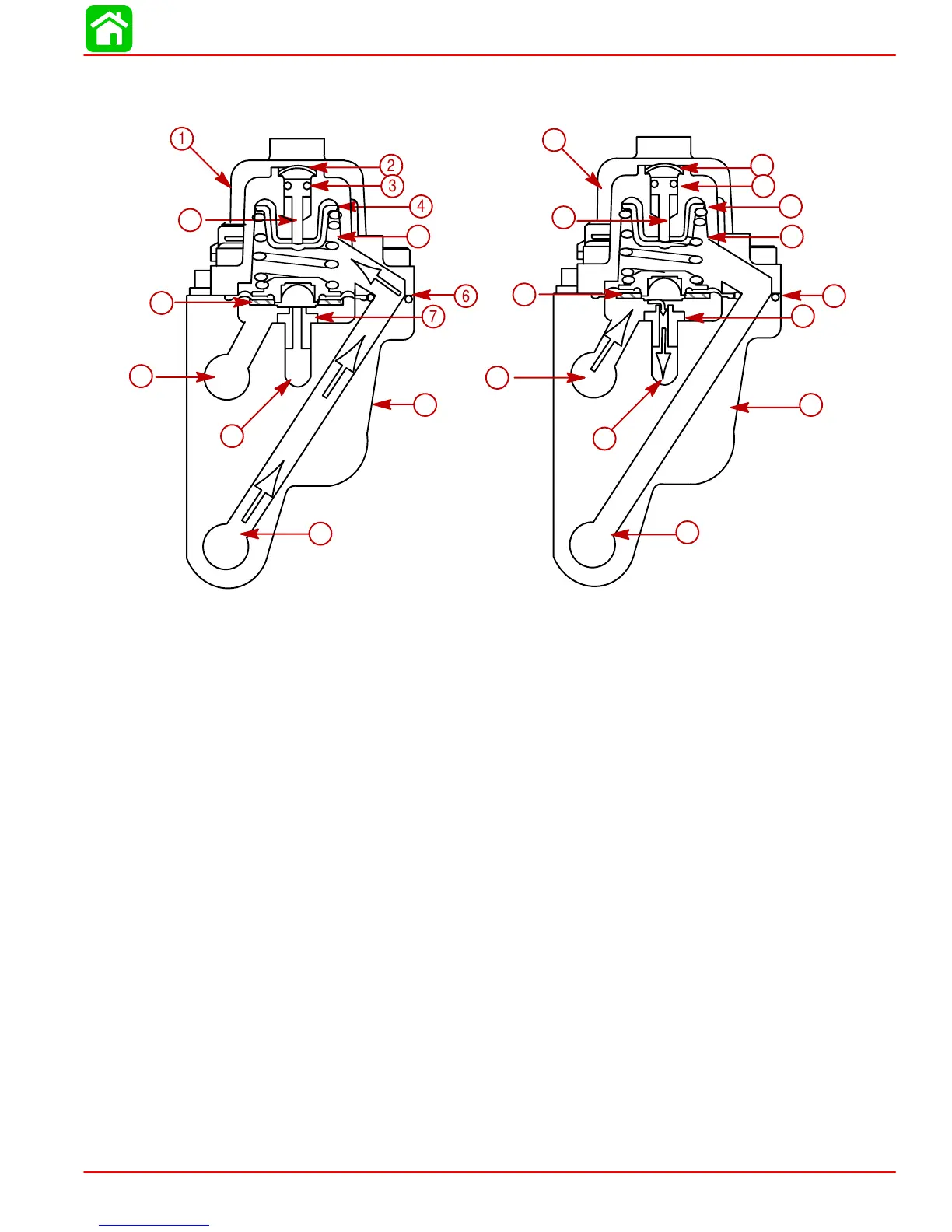

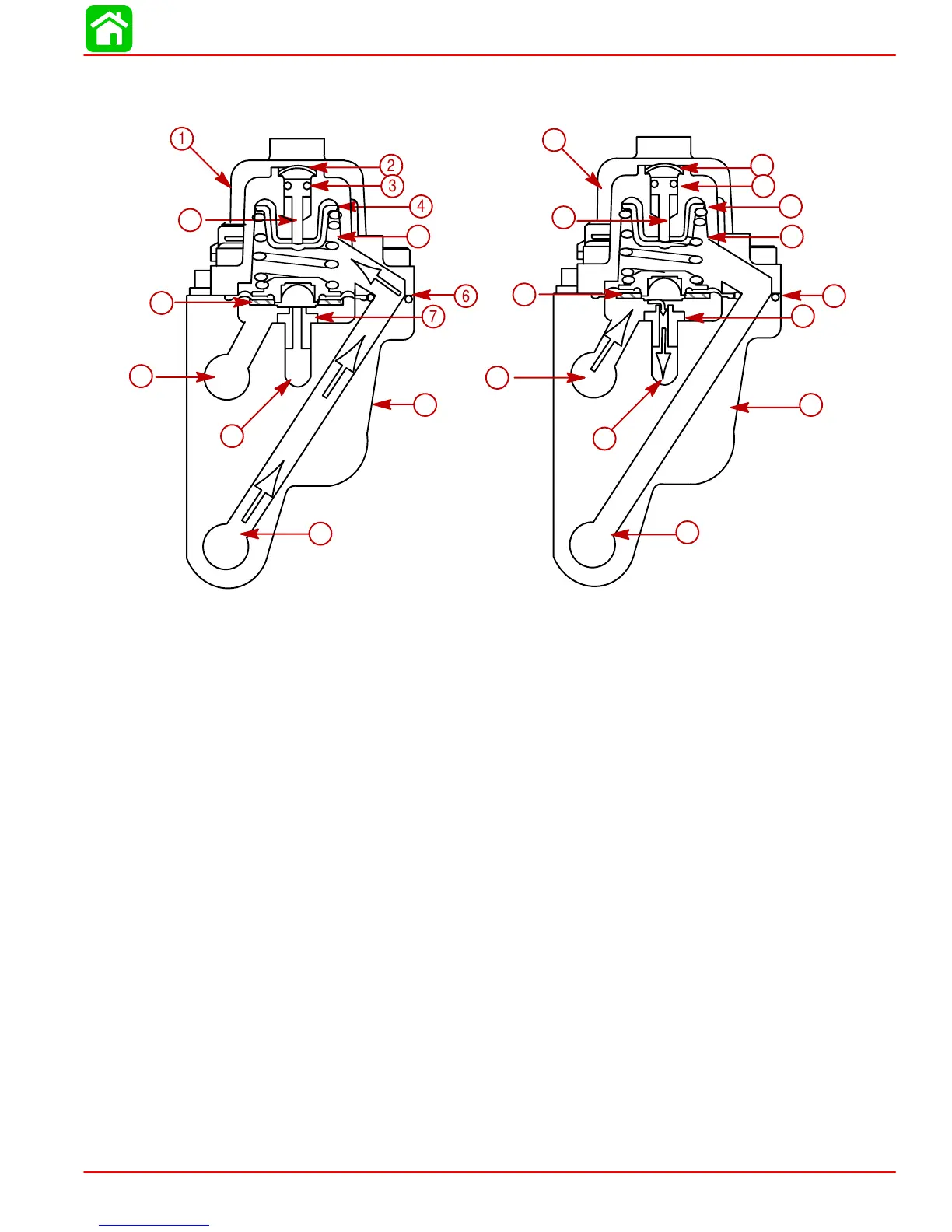

Fuel Pressure Regulator

Regulator Closed Regulator Open

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

11

1

2

3

4

5

6

7

8

9

10

11

12

13

1

2

3

4

5

6

7

8

9

10

11

12

13

1-Top Cover

2-Expansion Plug

3-O-ring

4-Spring Retainer

5-Spring

6-O-ring

7-Diaphragm Seat

8-Air Rail

9-Air Passage (from Air Compressor)

10 - Fuel Return Passage (to Vapor Separator)

11 - Fuel Inlet Passage (from Electric Fuel Pump)

12 - Diaphragm Assembly

13 - Calibration Screw (Do Not Turn)

The fuel pump is capable of delivering more fuel than the engine can consume. Excess

fuel flows through the fuel pressure regulator, interconnecting passages/hoses, fuel cool-

er, and back to the vapor separator tank. This constant flow of fuel means that the fuel

system is always supplied with cool fuel, thereby preventing the formation of fuel vapor

bubbles and minimizing the chances of vapor lock.

The fuel pressure regulator is calibrated to raise the fuel pressure to 10 psi above the air

pressure.

The fuel regulator is mounted on the port fuel rail, near the top. This regulator relies on

both air and spring pressure to control the fuel pressure. Inside the regulator assembly

is a 10 lb. spring, this spring holds the diaphragm against the diaphragm seat. The contact

between the diaphragm and diaphragm seat closes the passage between the incoming

fuel (from the electric fuel pump) and the fuel return passage.

When the engine is not running (no air pressure on the spring side of the diaphragm) the

fuel pressure required to move the diaphragm is 10 psi.

When the engine is running, air pressure from the air compressor (80 psi) is routed

through the air passages, to the spring side of the fuel pressure regulator diaphragm.

The air pressure (80 psi) and spring pressure (10 psi) combine to regulate system fuel

pressure to 90 psi - or 10 psi higher than the air pressure in the DFI system fuel/air rails.

Loading...

Loading...