DIRECT FUEL INJECTION

90-855347R1 JANUARY 1999 Page 3B-49

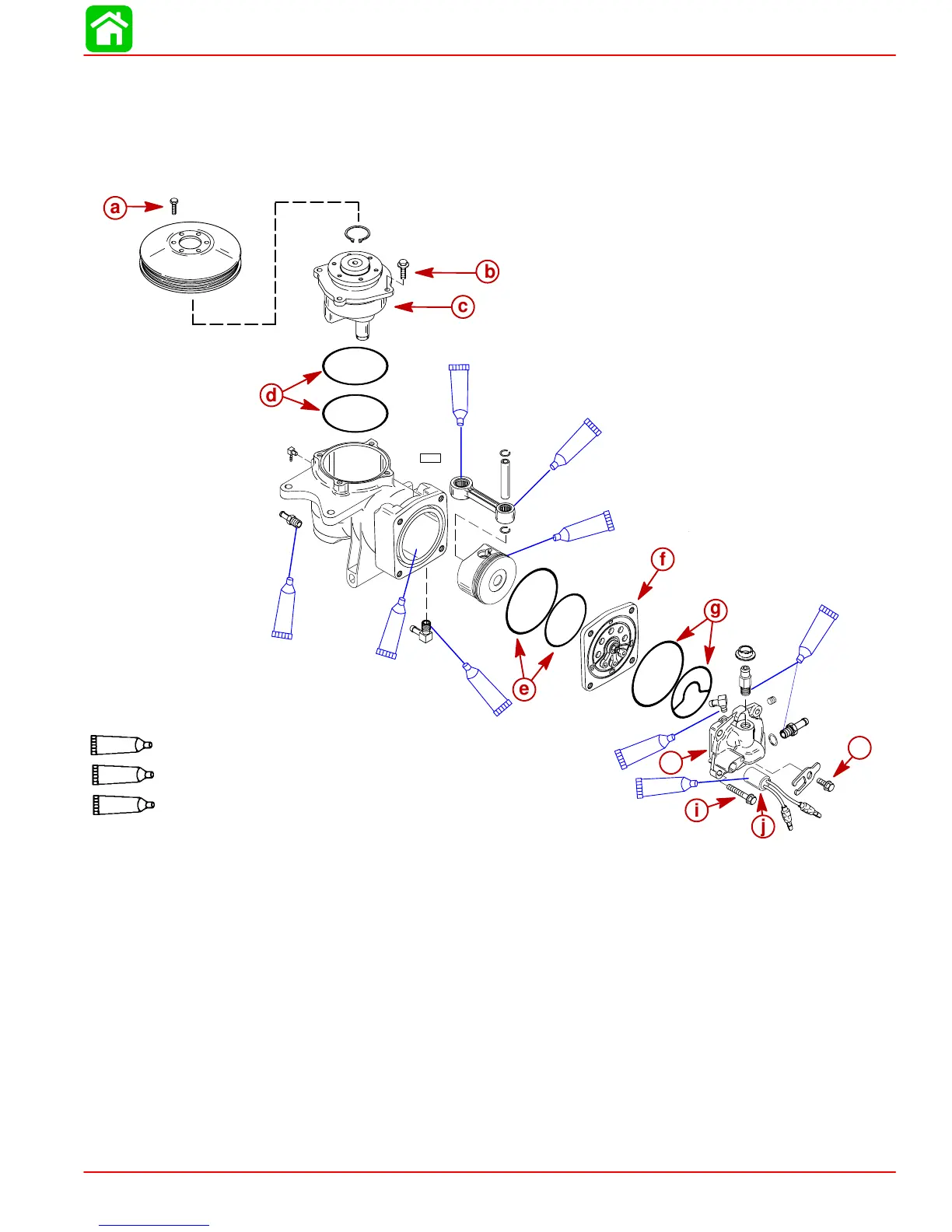

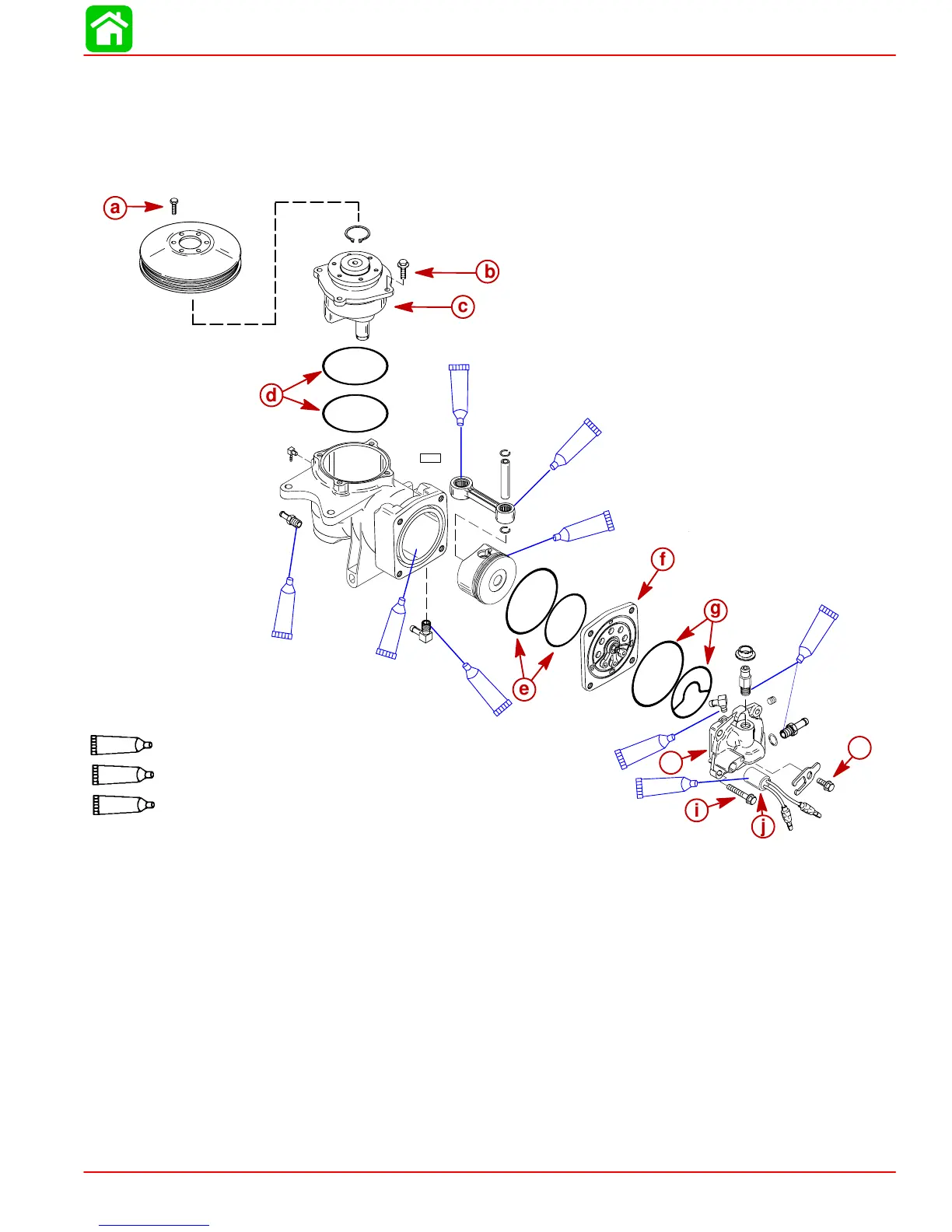

Air Compressor Disassembly/Reassembly

NOTE: If cylinder bore is scored, air compressor must be replaced as an assembly.

NOTE: The piston and rings are not sold separately. They must be replaced as an assem-

bly. The connecting rod and bearings are not sold separately. They must be replaced as

an assembly.

a

b

c

d

e

f

g

i

j

k

9

14

9

14

14

14

9

9

6

h

Dielectric Grease (92-823506--1)

6

Loctite PST Pipe Sealant (92-809822)

9

14

2 Cycle Outboard Oil (92-826666A24)

NOTE: End cap bearing and seal are not sold separately. End cap must be replaced as an assembly

NOTE: Piston Installation – use a metal hose clamp for piston ring compressor. Stagger piston ring openings.

a-Bolt [Torque to 100 lb. in. (11.5 Nm)]

b-Bolt (4 each) [Torque to 100 lb. in. (11.5 Nm)]

c-End Cap Assembly (Inspect bearing for

roughness)

d-O-rings (Inspect for cuts or abrasions)

e-O-rings (Inspect for cuts or abrasions)

f-Reed Plate (Inspect for broken or chipped

reeds/stops) Maximum Reed Stand-Open –

0.010 in. (0.254 mm)

g-O-rings (Inspect for cuts or abrasions)

h-Cylinder Head

i-Bolt [Torque to 20 lb. ft. (27 Nm)]

j-Temperature Sensor

k-Bolt [Torque to 20 lb. ft. (27 Nm)]

Loading...

Loading...