PRE-POWER CHECKS

TM-246193 Page 33Invision 352 MPa

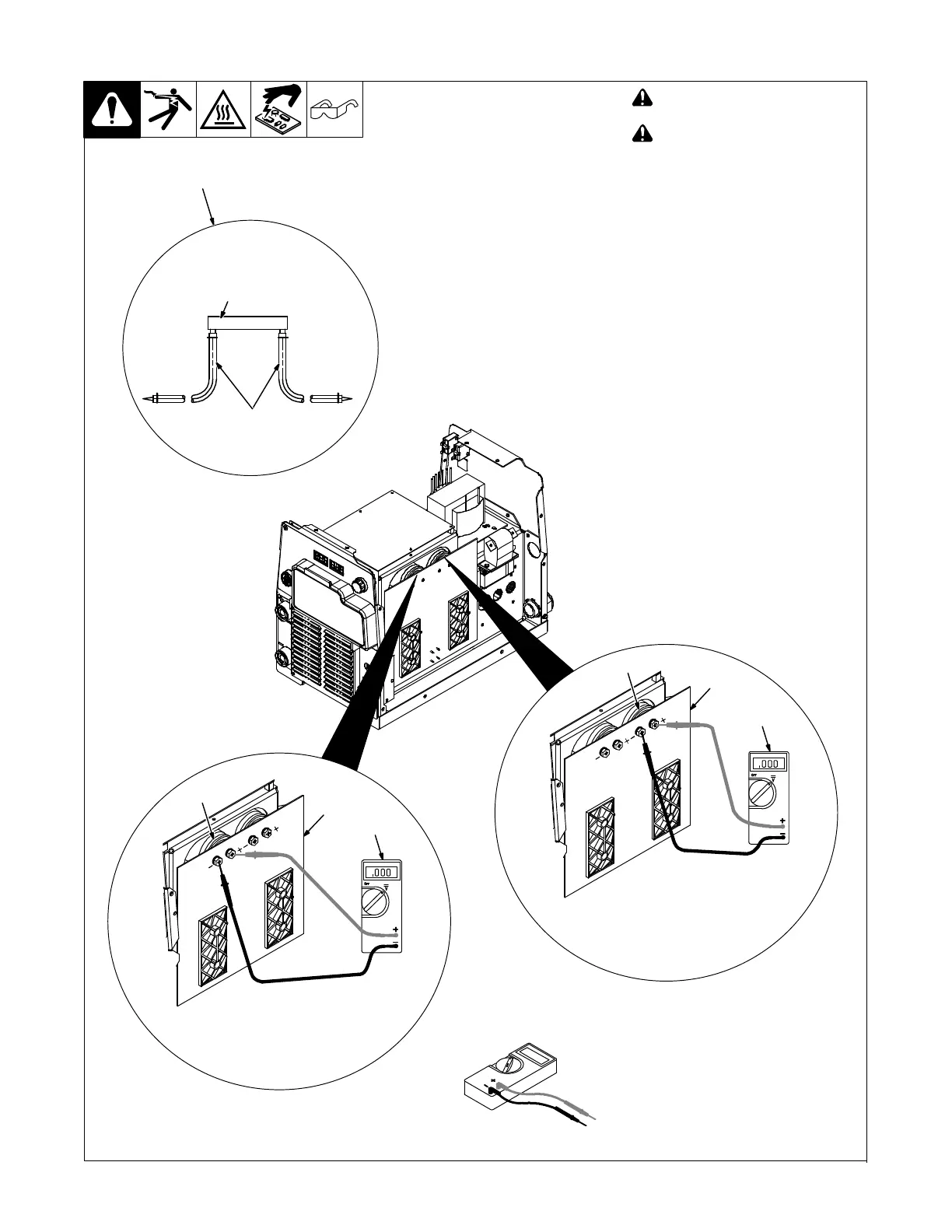

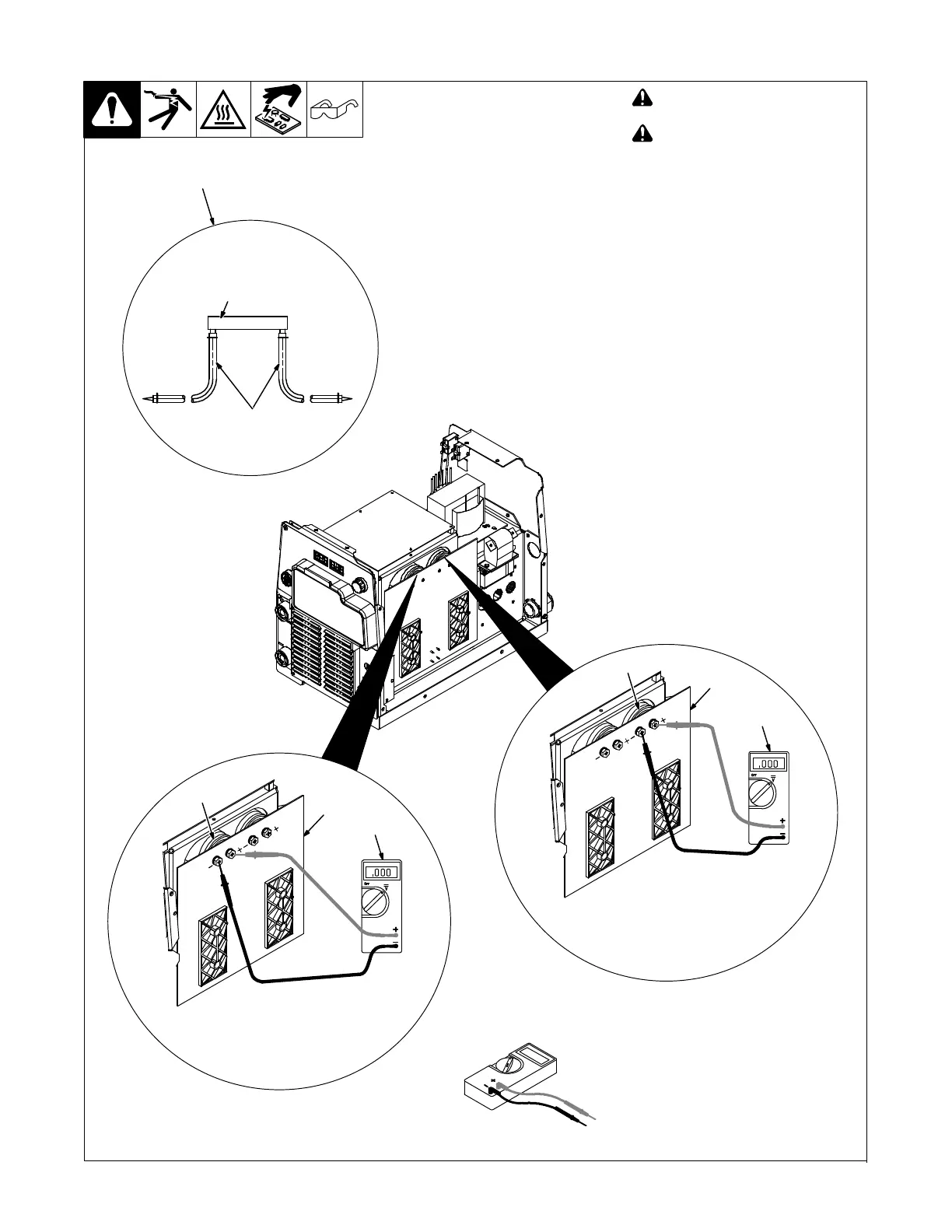

8-3. Measuring/Discharging Input Capacitor Voltage Before Working On Unit

! Turn Off welding power source,

and disconnect input power.

! Significant DC voltage can

remain on capacitors after unit is

Off. Always check the voltage as

shown to be sure the input capac-

itors have discharged before

working on unit.

Remove cover

1 Power Interconnect Board PC2

2 Voltmeter

3 Capacitor C12

Measure the DC voltage across C12

(+) Positive Terminal and C12 (−) Neg-

ative Terminal on PC2 as shown until

voltage drops to near 0 (zero) volts.

4 Capacitor C13

Measure the DC voltage across C13

(+) Positive Terminal and C13 (−) Neg-

ative Terminal on PC2 as shown until

voltage drops to near 0 (zero) volts.

If the capacitor voltage does not

drop to near zero after several min-

utes, use a bleeder resistor of be-

tween 25 and 1000 ohms, at least 5

watts, #16 AWG 1000 volts DC insu-

lating rating wire to discharge the

capacitor(s) .

5 Typical Bleeder Resistor

An example of a typical bleeder resistor

is shown on this page.

Proceed with pre-power checks.

1

2

Positive (+) lead to C12 (+) terminal,

Negative (−) lead to C12 (−) terminal

3

1

2

Positive (+) lead to C13 (+) terminal,

Negative (−) lead to C13 (−) terminal

4

Test Equipment Needed:

Typical Bleeder Resistor

25 to 1000 ohm,

5 watt resistor

#16 AWG 1000 volts DC

insulation rating, approx.

3 in. (76 mm) leads

5

Ref. 803721-B / 907161

Loading...

Loading...