Always check unit before applying power (see Sections 8-2 thru 8-11).

TM-246193 Page 48 Invision 352 MPa

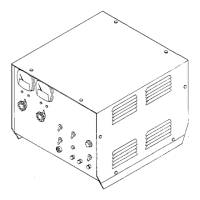

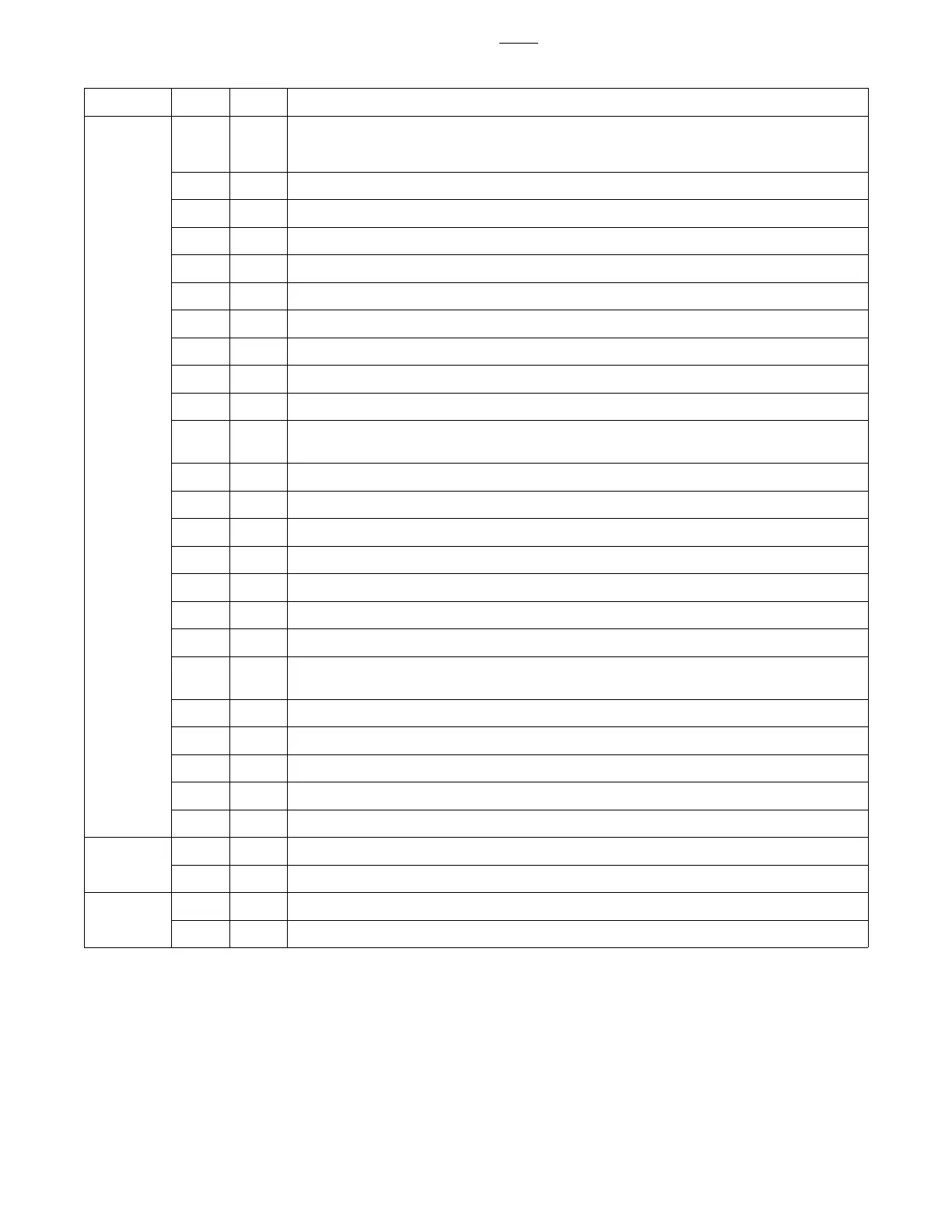

Section 8-20. Control Board PC1 Test Point Values (Continued)

Receptacle Pin Type Value

RC6 1 Input Output reference; 1 volt DC per 42.5 amperes of weld output when machine is under load; when machine

at idle, process set to MIG with .035 STL wire and ARGN CO2 gas selected; adjust control set to 10V

preset = 8.2V; adjust control set 38V preset = 9.4V

2 Input Voltage feedback; 1 volt DC per 10 volts DC of weld output

3 Output Current feedback; 1 volt DC per 100 amperes of weld output

4 Not Used

5 Input Output enable; 0 volts DC = ON, +12.5 volts DC = OFF

6 Not Used

7 Not Used

8 Not Used

9 Input Fan enable; +5 volts DC = fan on, −15 volts DC = fan off

10 Not Used

11 Output Main transformer overcurrent detect; +.7 volts DC = OK, +3.3 volts DC = T1 primary overcurrent = HELP

1

12 Not Used

13 Input +3.0 volts DC reference voltage for thermistors

14 GND Circuit common referenced to chassis

15 Output Secondary side thermistor return; +1.2 volts DC at 25

C thermistor temperature

16 GND Circuit common referenced to chassis

17 Output Primary side thermistor return; +1.2 volts DC at 25

C thermistor temperature

18 GND Circuit common referenced to chassis

19 Output Foldback; decreases weld output if input bus voltage drops, 0 volts = OK, +15 volts DC 15Khz pwm

squarewave = foldback

20 GND Circuit common referenced to chassis

21 Output +24 volts DC, unregulated DC voltage with respect to GND

22 Output +24 volts DC, unregulated DC voltage with respect to GND

23 Output −24 volts DC, unregulated DC voltage with respect to GND

24 Output −24 volts DC, unregulated DC voltage with respect to GND

RC7 1 Output +3 volts DC reference voltage for secondary side thermistor

2 Input Secondary side thermistor return; +1.2 volts DC at 25

C thermistor temperature

RC8 1 Output +3 volts DC reference voltage for primary side thermistor

2 Input Primary side thermistor return; +1.2 volts DC at 25

C thermistor temperature

Loading...

Loading...