21Installation, Operations & Maintenance Manual

NOTE:

Synthetic oils are available that span the entire

temperature range. Contact Milton Roy for

further information.

Recommended Oil

Any equivalent oil is acceptable.

Nominal Oil Capacity

2.10 PIPING

General

Refer to Figure 15 for a diagram of a typical Piping

and Instrumentation Diagram.

Support all piping connections to the pump so

that no stress is placed on pump fittings. In

no case should the piping be sprung to make

the connections to the pump. The suction and

discharge cartridge pipe connections can be

positioned within an arc of approximately 150° to

facilitate piping to pump.

Flush and blow out all pipelines before connecting

the pump. This eliminates any foreign matter

that might seriously damage the internal working

parts of the liquid end. Install a 20 mesh Y-type

strainer that is sized to remove foreign particles

with minimum pressure drop in the suction line of

the pump. It is also recommended to perform a

leak test of the system with a neutral liquid before

pressured start-up of the nal installation.

Install shut-off valves, with unions on the pump side

of the valves, in the suction and discharge lines to

facilitate servicing.

Use extreme care in piping to plastic liquid end

pumps with rigid pipe such as PVC. If excessive

stresses or vibration is unavoidable, flexible

connections are recommended.

NOTE:

Many pipe joint compounds are not suitable

for use with plastic pipe and, if used, will cause

stress cracking at the connection. Use only

compounds commended for use with plastic

materials.

Suction Piping

The suction piping must be absolutely tight and leak

free. For mRoy pumps on water-like solutions we

recommend that the suction pipe be ¾” minimum

diameter and a maximum of 6 feet (2 meters) long.

The intent is that the piping must be designed to

provide an adequate net positive suction head

(NPSH). Obtain our NPSH Calculation software at

the Milton Roy website (www.miltonroy.com). If

assistance in determining NPSH is needed, contact

the Milton Roy Aftermarket Service department

through the website (www.miltonroy.com)

A ooded suction is recommended for optimum

service life and maintenance-free operation.

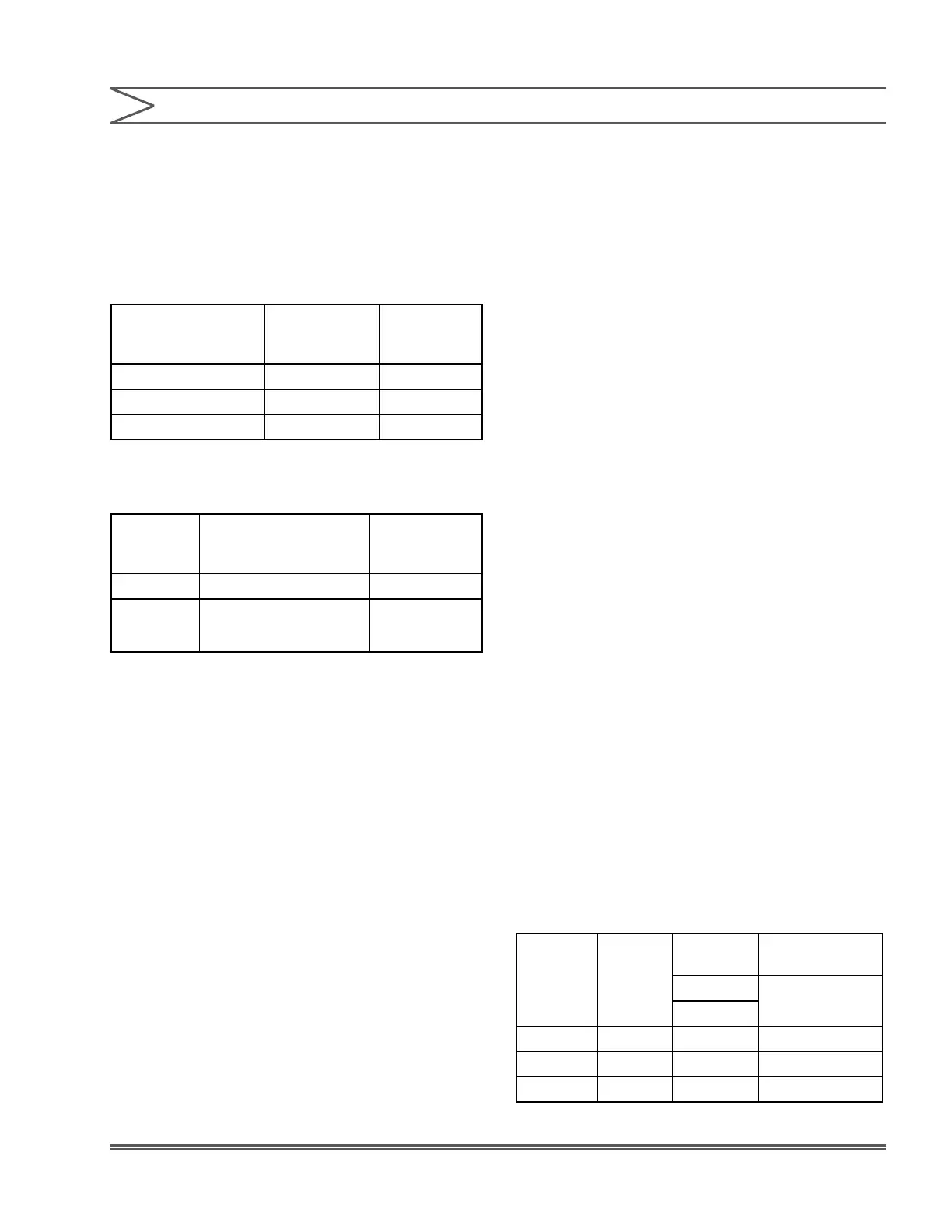

However, the mRoy pump can operate with less

than ooded suction if necessary, in accordance

with the following schedule shown in the chart

below.

Model

Number

Min. NPSH Max. Li

(PSI)

(Ft. (meter) H2O)

(Bar)

mRoy A RA 10 10 (3)

mRoy H/T RH or RT 10 10 (3)

mRoy P RP 10 10 (3)

SECTION 2 - INSTALLATION

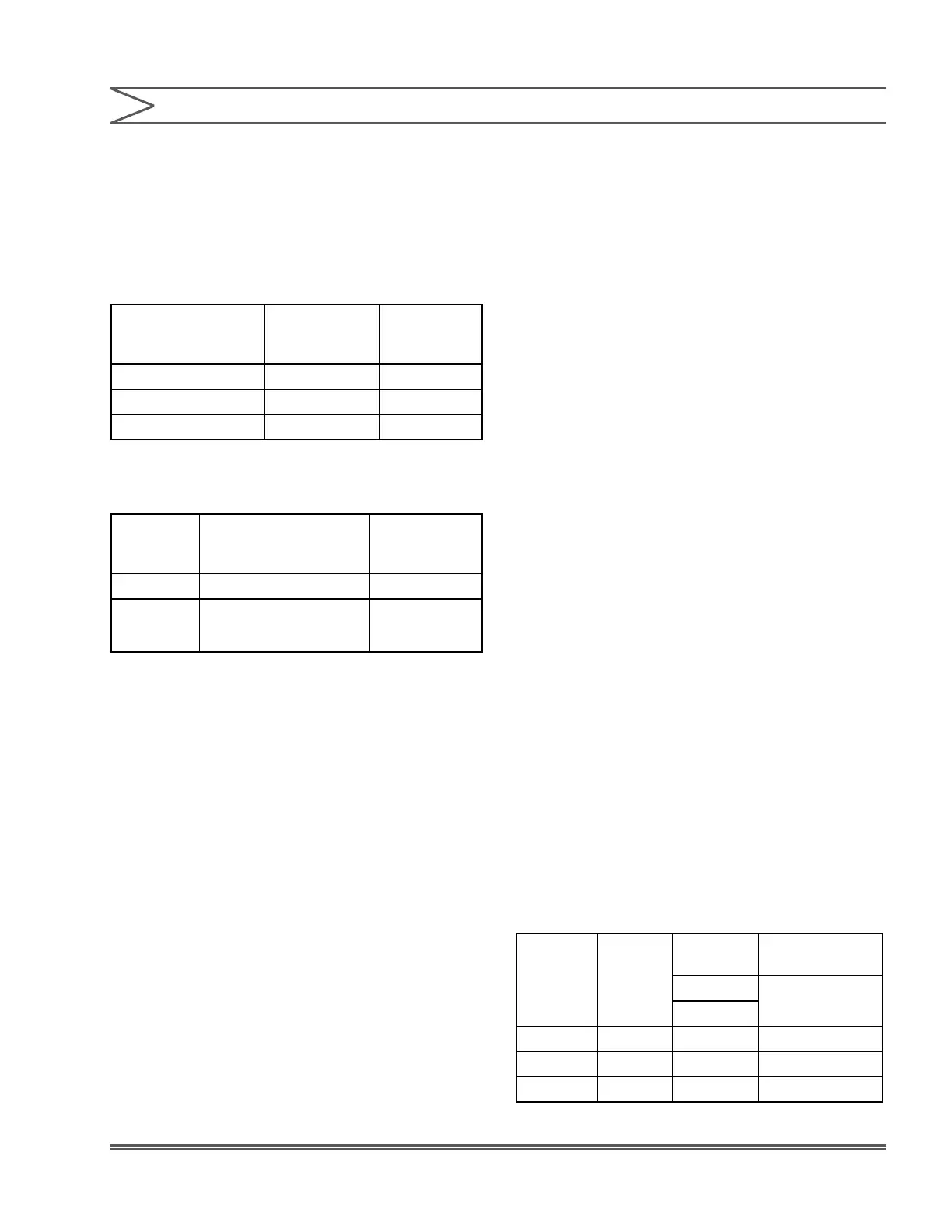

Oil Type

Ambient

Temp. 15-50 °F

(-9-10 °C)

Ambient

Temp. Above

50°F(10°C)

AGMA Spec No. 2 EP No. 5 EP

Zurn Oil Co No. EP 35 No. EP 95

ISO Grade 68 220

Oil Type

Ambient

Temp. 15-50 °F (-9-10

°C)

Ambient

Temp. Above

50°F(10°C)

AGMA Spec No. 2 EP No. 5 EP

Zurn Oil Co

No. EP 35 No. EP 95

Loading...

Loading...