22 Installation, Operations & Maintenance Manual

Refer to “Installation with Suction Lift,” which outlines

limiting conditions if suction lift requirements are

anticipated.

The supply tank should incorporate a low-level

switch to cut off the pump motor before the suction

intake is exposed to air. Otherwise, the pump may

occasionally run dry.

Discharge Piping

The installation of an external Safety Valve is

recommended, since the pump’s internal relief

valve is not intended to protect the piping system.

Refer to “Setting the Relief Valve” in Section 3, for

further relief valve discussion. (Milton Roy offers a

complete line of back pressure and safety valves).

For satisfactory metering and capacity control,

the discharge pressure at the pump must be

50 PSI (3.5 Bar) minimum for the mRoy A and

70 PSI (4.8 Bar) minimum for the mRoy B.

Therefore, when the pump is to discharge into

an open system, a back pressure device must be

installed in the pump discharge line.

REMOTE HEAD SYSTEMS: DO

NOT INSTALL A BACK

PRESSURE SPRING IN DISCHARGE BALL CHECK CARTRIDGE

OF DIAPHRAGM HEADS WHICH ARE “REMOTE MOUNTED”

(NOT ATTACHED TO THE MAIN HOUSING). A SEPARATE

BACK PRESSURE VALVE MUST BE INSTALLED IN THE

SECTION 2 - INSTALLATION

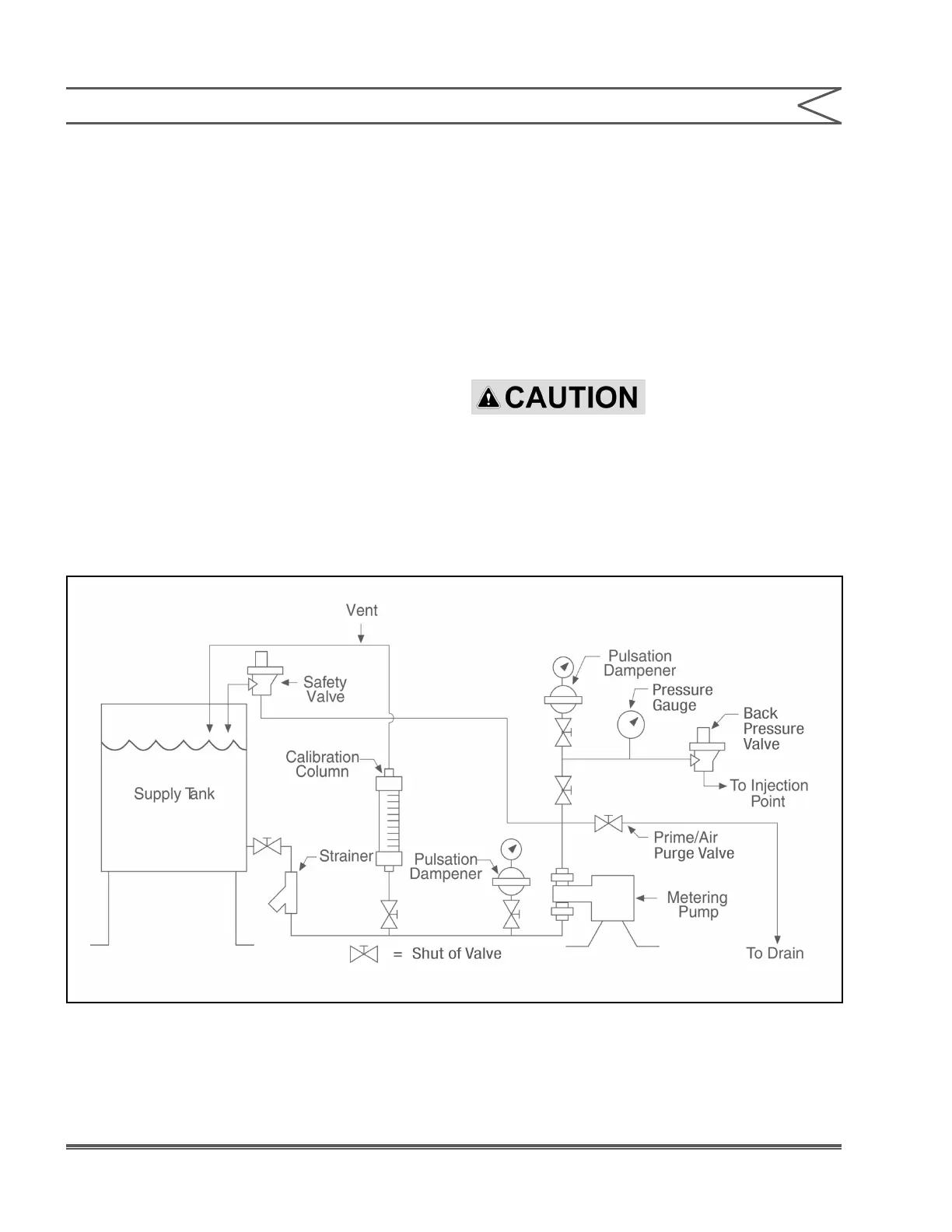

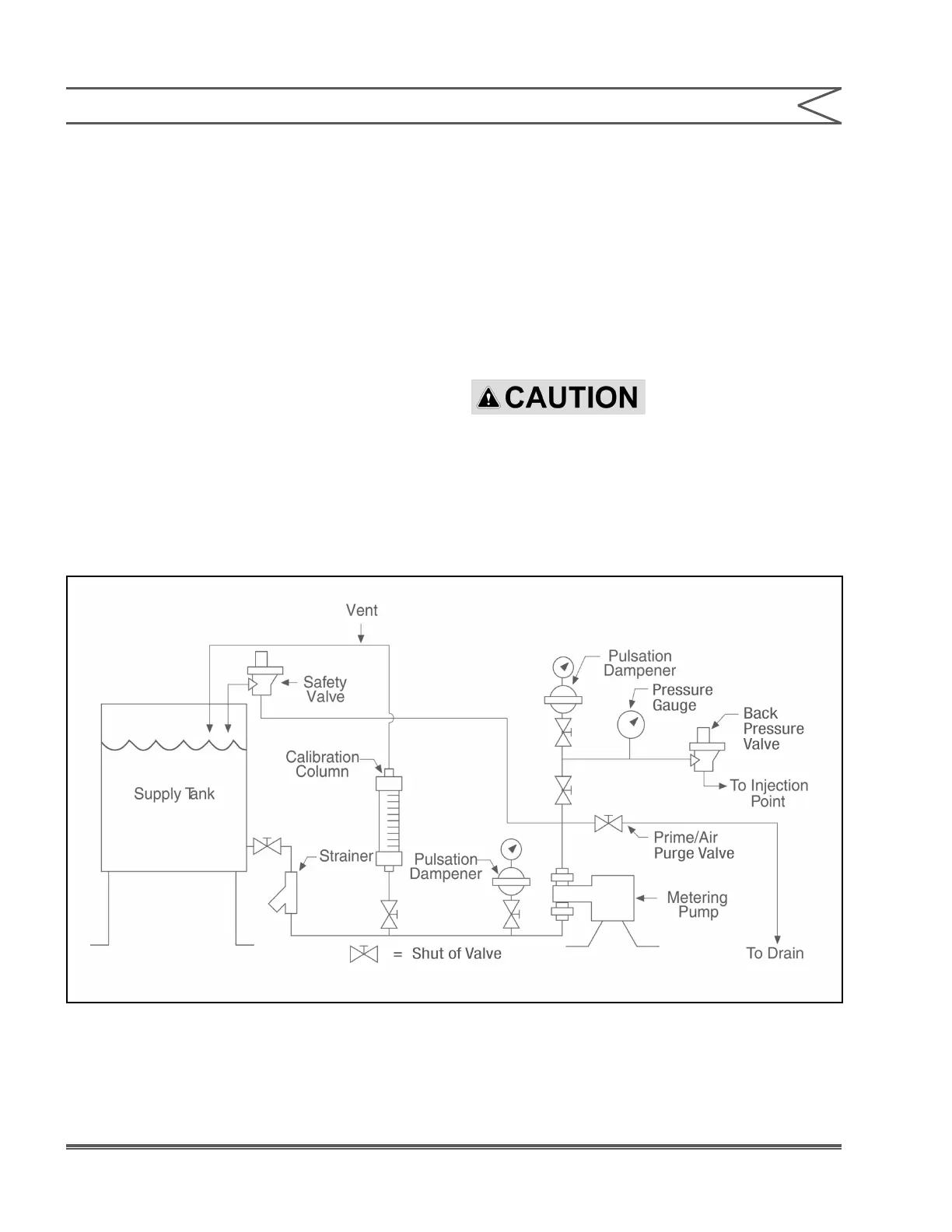

Figure 15. Typical Piping and Instrumentation Diagram

Loading...

Loading...