A7™ Service Manual 046-006272-00 1 - 15

Theory of Operation Gas Flow

1.3.4.2 Gas Supplies

The A7 anesthesia machine supports three gas supplies: O2, N2O and AIR. All the gas supply

interfaces are designed based on IEC 60601-2-13, which prevents misconnection between different

gases. The A7 gas supply inlet assemblies comprise the pipeline gas supply inlet assembly and

cylinder gas supply inlet assembly.

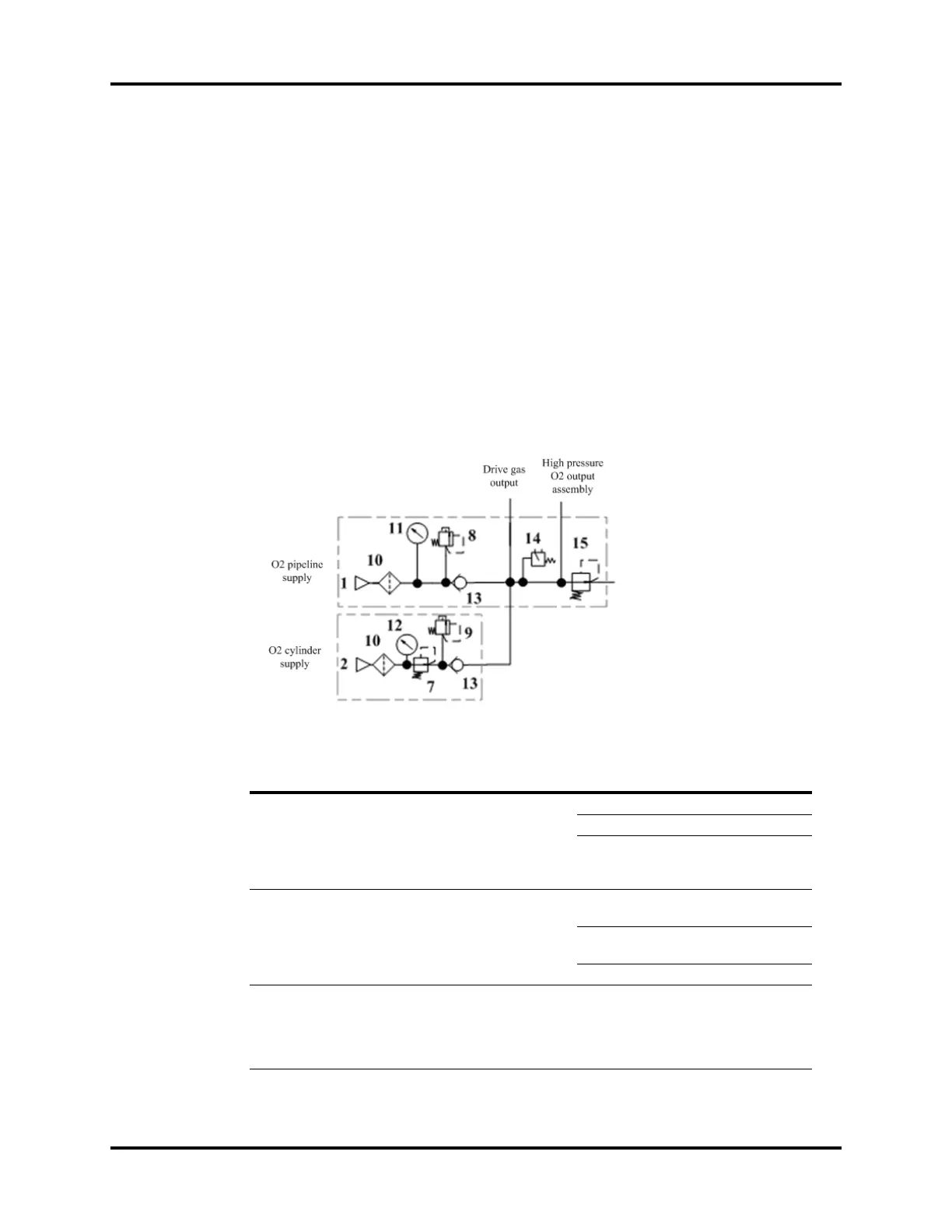

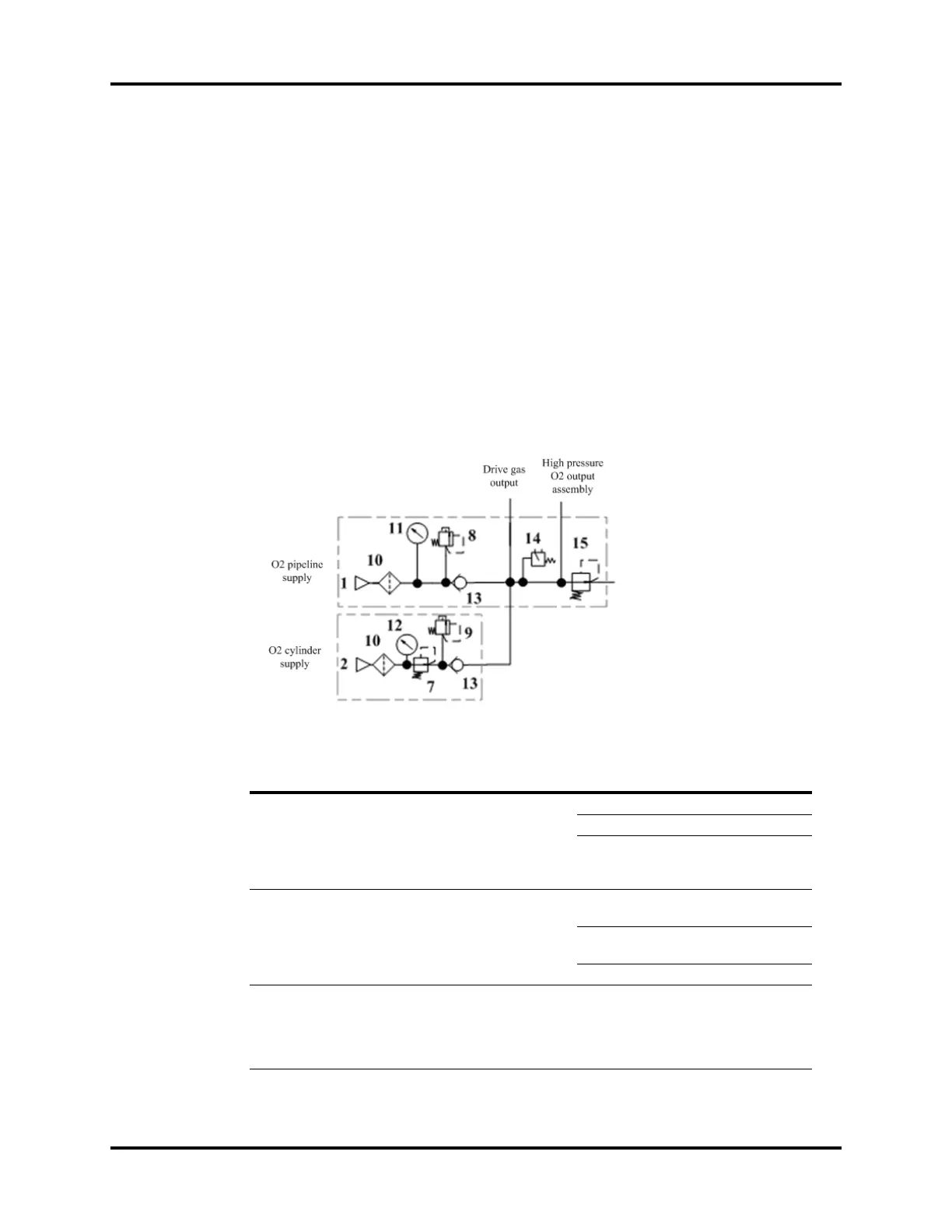

The following describes the O2 gas flow. The difference between the O2 and the AIR/N2O limbs lies

in that the drive gas output and high-pressure O2 output are available at the upstream end of the

regulator (15) on the O2 limb. The configurations of other components are the same. The O2 pipeline

supply inlet assembly includes filter 10, pressure gauge 11, pressure relief valve 8, check valve 13,

pressure switch 14 and regulator 15. The cylinder gas supply inlet assembly includes the filter (10),

pressure gauge (12), pressure reducing valve (7), pressure relief value (9), check valve (13), pressure

switch (14) and regulator (15). Where, the pressure switch (14) and regulator (15) are shared by the

pipeline and cylinder gas supply limbs. The following figure is the block diagram.

The following table lists parameters of key components.

Name Supplier Description of Functions Key Index

Regulator Camozzi

Adjusts pressure and ensures

constant output pressure at the

regulator outlet.

Applied to compressed air, O2 and N2O .

Pressure range: 0.05 to 1 MPa (7 to 145 psi)

Flow: 160 L/min (At 10 bar (145 psi) inlet

pressure, 4bar (58 psi) outlet pressure, with

0.5bar (7 psi) drop)

Pressure

switch

AIR LOGIC

Reports an alarm when the gas

supply is insufficient. Pressure

switches are configured on the

O2, N2O and air limbs.

Precision: 0.5 to 100 PSI, +/- 0.5 tolerance on

the initial starting pressure

Alarm type: an alarm will be reported when

the gas supply pressure reduces to 32 PSI.

Pressure resistance: 300 PSI

Pressure

relief valve

Mindray Prevents gas pressure too high.

Startup pressure: 758 kPa±20 kPa (110 psi ±

2.9 psi)

Leakage volume requirement: The leakage

volume should be smaller than 5 ml/min for

a 600 kPa pressure relief valve.

Loading...

Loading...