32

33

18

17

30

30

35

37

21

3

4

25

28

7

5

15

13

29

23

32

14

6

7

24

36

12

26

38

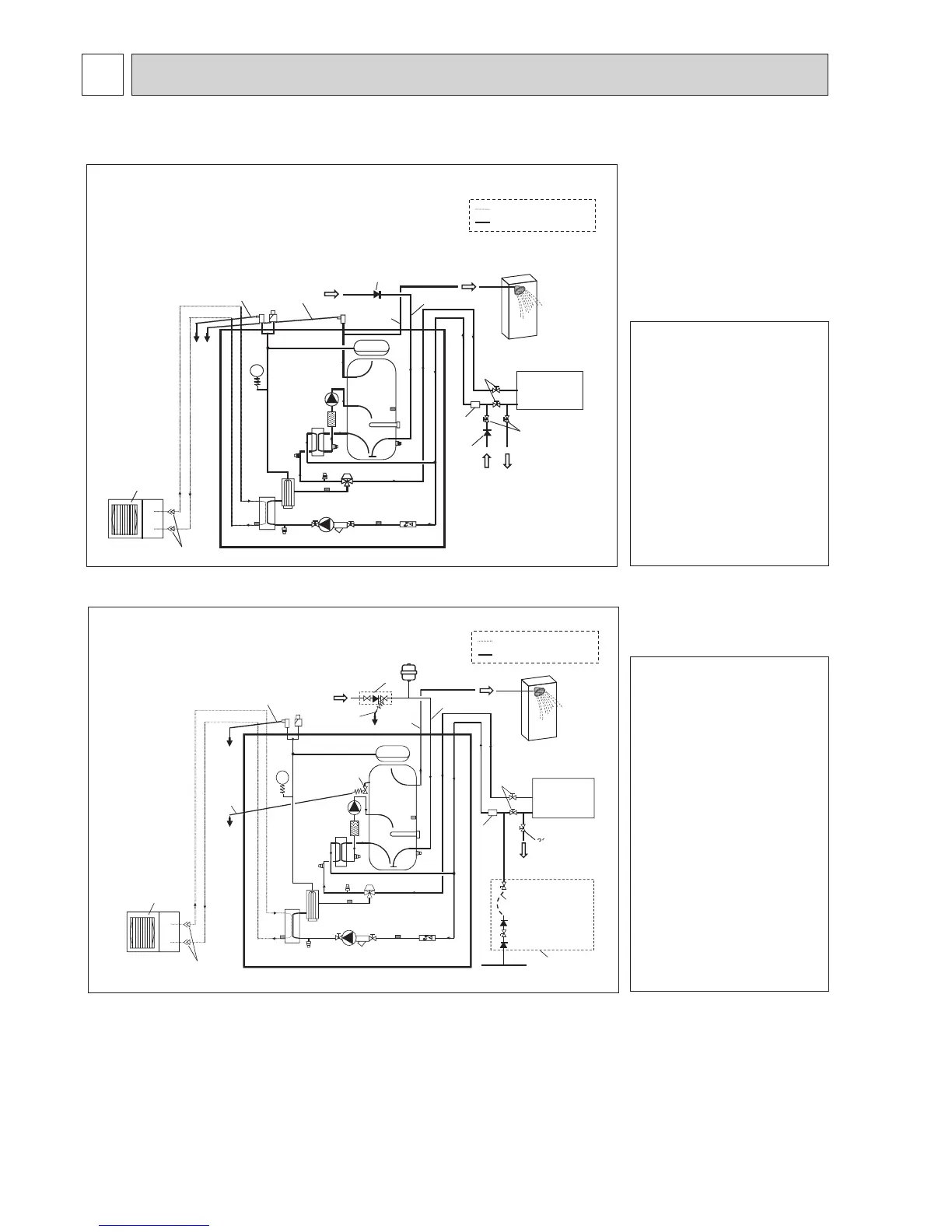

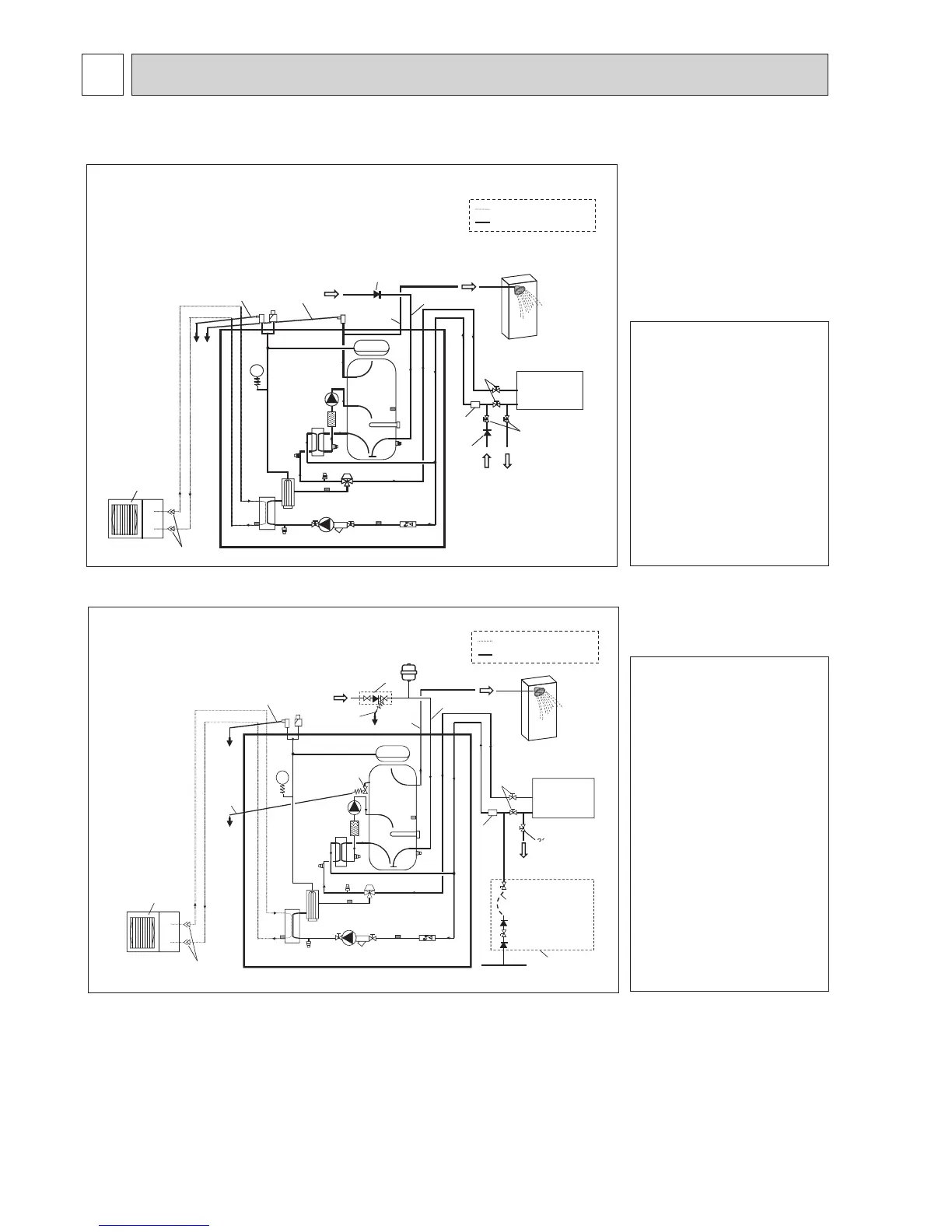

WATER SYSTEM DIAGRAM

8

•Refer to <Table 4-1 and 4-2> for the part names.

*1Refertothefollowingsection[Localsystem].

<E*ST20*-*M**C > (Split model system)

<EHST20*-MHCW>(UKSplitmodelsystem)<Example>

<Figure8-2>

<Figure8-1>

Notes:

•Toenabledrainingofthecylinderunit

an isolating valve should be posi-

tioned on both the inlet and outlet

pipework.

•Besuretoinstallastrainerontheinlet

pipeworktothecylinderunit.

•Suitabledrainpipeworkshouldbeat-

tached to all relief valves in accord-

ancewithyourcountry’sregulations.

•Abackowpreventiondevicemustbe

installed on the cold water supply

pipework(IEC61770)

• When using components made from

different metals or connecting pipes

made of different metals insulate the

joints to prevent any corrosive reac-

tion taking place which may damage

thepipework.

Flare connection

Flare connection

Cylinder unit

Cylinder unit

Drain

Drain

Drain

Drain

Drain

Drain

Coldwater

Coldwater

DHW

DHW

Local system

Refrigerantpipe

Water pipe

Local system

Flexiblehose

(Temporary connection)

Water

supply

Notes:

•

To enable drainingofthecylinderunit

anisolatingvalveshouldbepositioned

onboth the inlet and outlet pipework.

Novalveshouldbettedbetweenthe

expansionvalve(item35)andthecyl-

inder unit (safety matter).

•Besuretoinstallastrainerontheinlet

pipeworktothecylinderunit.

•Suitabledrainpipeworkshouldbeat-

tached to all relief valves in accord-

ancewithyourcountry’sregulations.

• When using components made from

different metals or connecting pipes

made of different metals insulate the

joints to prevent any corrosive reac-

tion taking place which may damage

anypipework.

•Fillingloop’sexiblehosemustbere-

movedfollowingthellingprocedure.

Item provided with unit as loose ac-

cessory.

•Installtheinletcontrolgroup(item35)

abovetheleveloftheT&Preliefvalve

(item21).Thiswillensure DHW tank

willnotrequiredrain-downtoservice/

maintaintheinletcontrolgroup.

Refrigerantpipe

Water pipe

Loading...

Loading...