0

-25

-20

-15

-10

-5

5

0

10 20 30 40 50

41

Filling the cylinder unit (Primary circuit)

Draining the cylinder unit

WARNING: DRAINED WATER MAY BE VERY HOT

1.Beforeattemptingtodrainthecylinderunitisolatefromtheelectricalsupplytopreventtheimmersionandboosterheatersburningout.

2.IsolatecoldwaterfeedtoDHWtank.

3.AttachahosetotheDHWtankdraincock(No.23and24onFigure4-1and4-2).Thehoseshouldbeabletowithstandheatasthedrainingwatercouldbevery

hot.ThehoseshoulddraintoaplacelowerthantheDHWtankbottomtoencouragesiphoning.

Openahotwatertaptostartdrainingwithoutavacuum.

4. When the DHW tank is drained close drain cock and hot tap.

5.Attachhosetowatercircuitdraincock(No.7onFigure4-1and4-2).Thehoseshouldbeabletowithstandheatasthedrainingwatercouldbeveryhot.Thehose

shoulddraintoaplacelowerthantheboosterheaterdraincocktoencouragesiphoning.Openthepumpvalveandthestrainervalve.

6.Waterremainsinthestrainerstillafterthecylinderunitwasdrained.

Drainthestrainerbyremovingthestrainercover.

Initialllprocedure:

1.Ensureallpipejointsandttingsaretightandsecure.

2. Open the most distant DHW tap/outlet.

3.Slowly/graduallyopenthemainswatersupplytobeginllingunitandDHWpipework.

4.Allowmostdistanttaptorunfreeandrelease/purgeresidualairfrominstallation.

5.Closetap/outlettoretainfullychargedsystem.

Initialushprocedure:

1.Energisesystemtoheat-upcylindercontentstoatemperatureofapprox.30–40°C.

2.Flush/drainthewatercontentstoremoveanyresidue/impuritiesresultingfromtheinstallationworks.Usethecylinderdraincocktosafelydischargethewarmed

watertodrainviaasuitablehose.

3.Oncompletion,closedraincock,re-llsystemandresumesystemcommissioning.

Filling the cylinder unit (Potable/DHW circuit)

1.Checkandchargeexpansionvessel.

2.Checkallconnectionsincludingfactoryttedonesaretight.

3.Insulatepipeworkbetweencylinderunitandoutdoorunit.

4.

Thoroughlycleanandush,systemofalldebris.(

Refer to 4.2 in the installation manual.)

5.Fillcylinderunitwithpotablewater.Fillprimaryheatingcircuitwithwaterandsuitableanti-freezeandinhibitorasnecessary.Alwaysuseallingloopwith

doublecheckvalvewhenllingtheprimarycircuittoavoidbackowcontaminationofwatersupply.

• Anti-freezeshouldalwaysbeusedforpackagedmodelsystems.Itistheresponsibilityoftheinstallertodecideifanti-freezesolutionshouldbeusedinsplit

modelsystemsdependingoneachsite’sconditions.Corrosioninhibitorshouldbeusedinbothsplitmodelandpackagedmodelsystems.

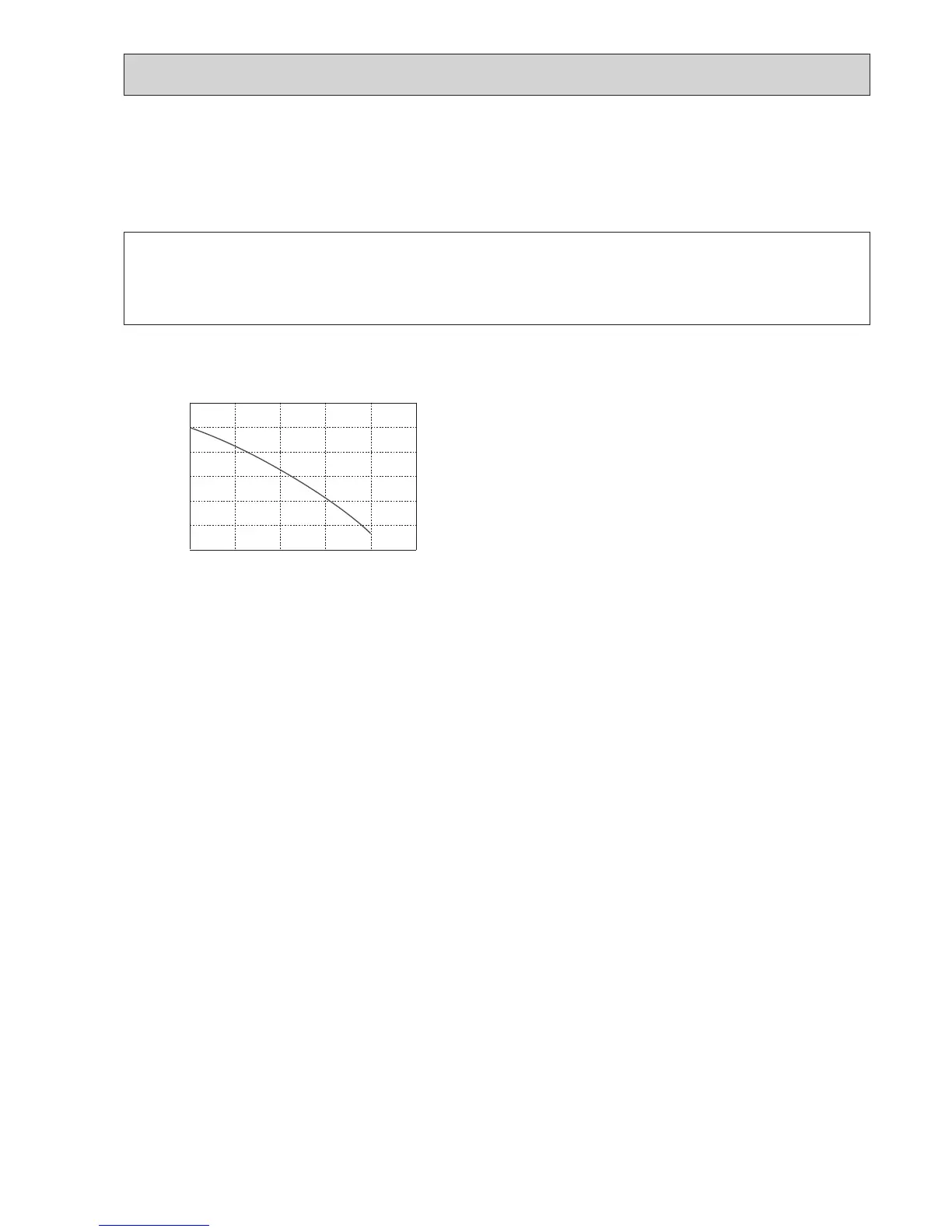

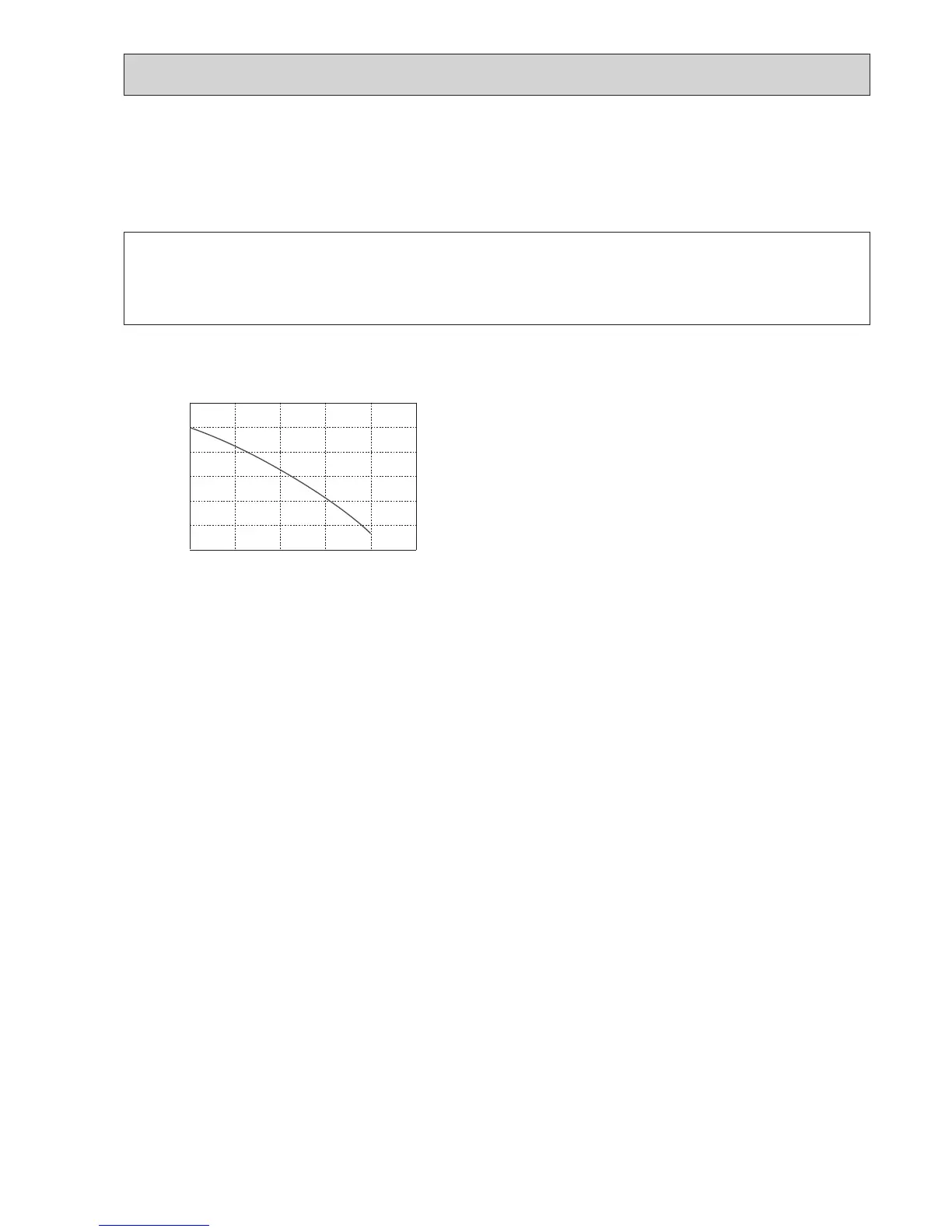

Figurebelowshows freezingtemperatureagainstanti-freezeconcentration.ThisgureisanexampleforFERNOXALPHI-11.Forother anti-freeze, please

refer to relevant manual.

• Whenconnectingmetalpipesofdifferentmaterialsinsulatethejointstopreventacorrosivereactiontakingplacewhichwilldamagethepipework.

6.Checkforleakages.Ifleakageisfound,retightenthenutontotheconnections.

7. Pressurise system to 1 bar.

8.Releasealltrappedairusingairventsduringandfollowingheatingperiod.

9.Topupwithwaterasnecessary.(Ifpressureisbelow1bar)

Freezingtemperature[°C]

Anti-freezeconcentration[%]

Loading...

Loading...