Maintenance

MTS Landmark™ Tabletop Load Units - Product Information 111

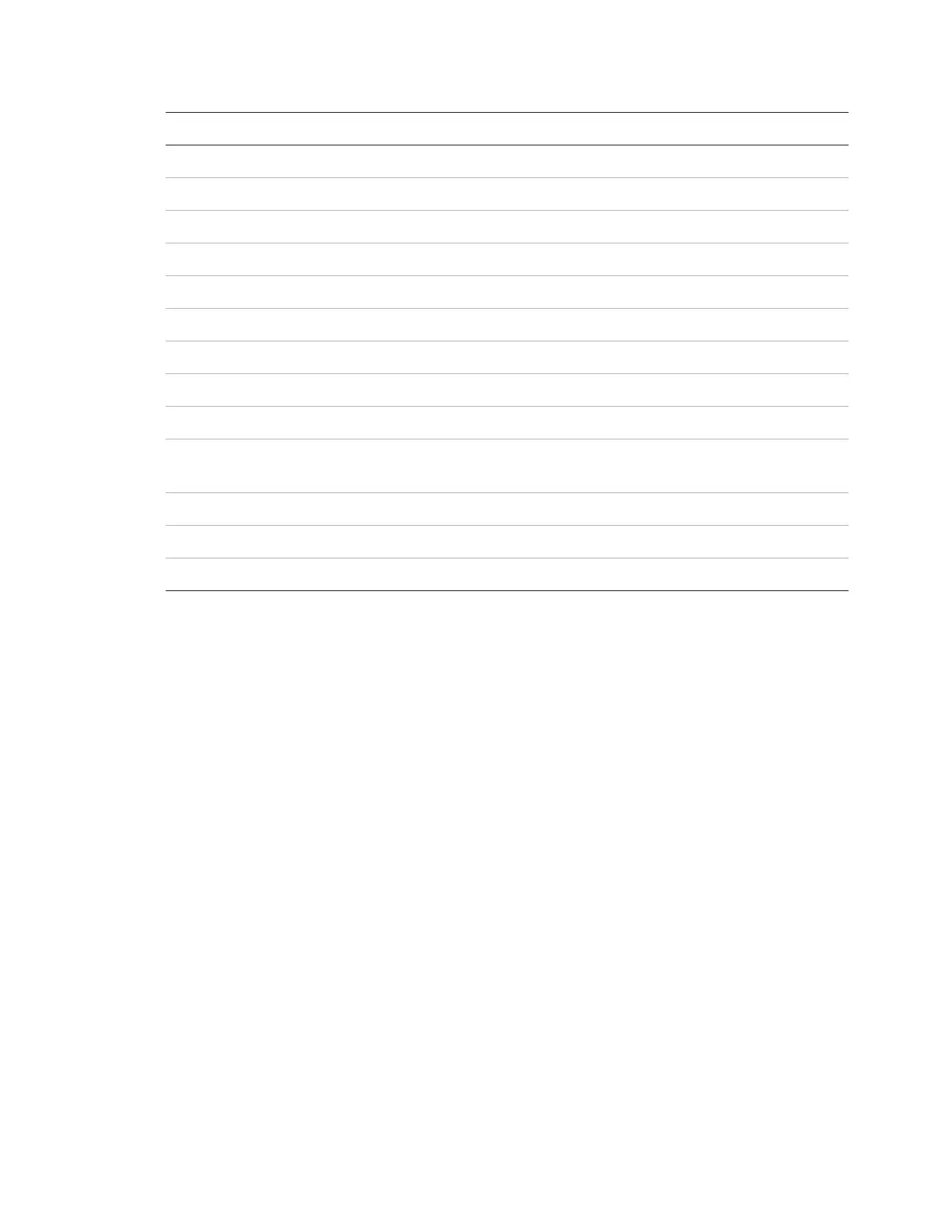

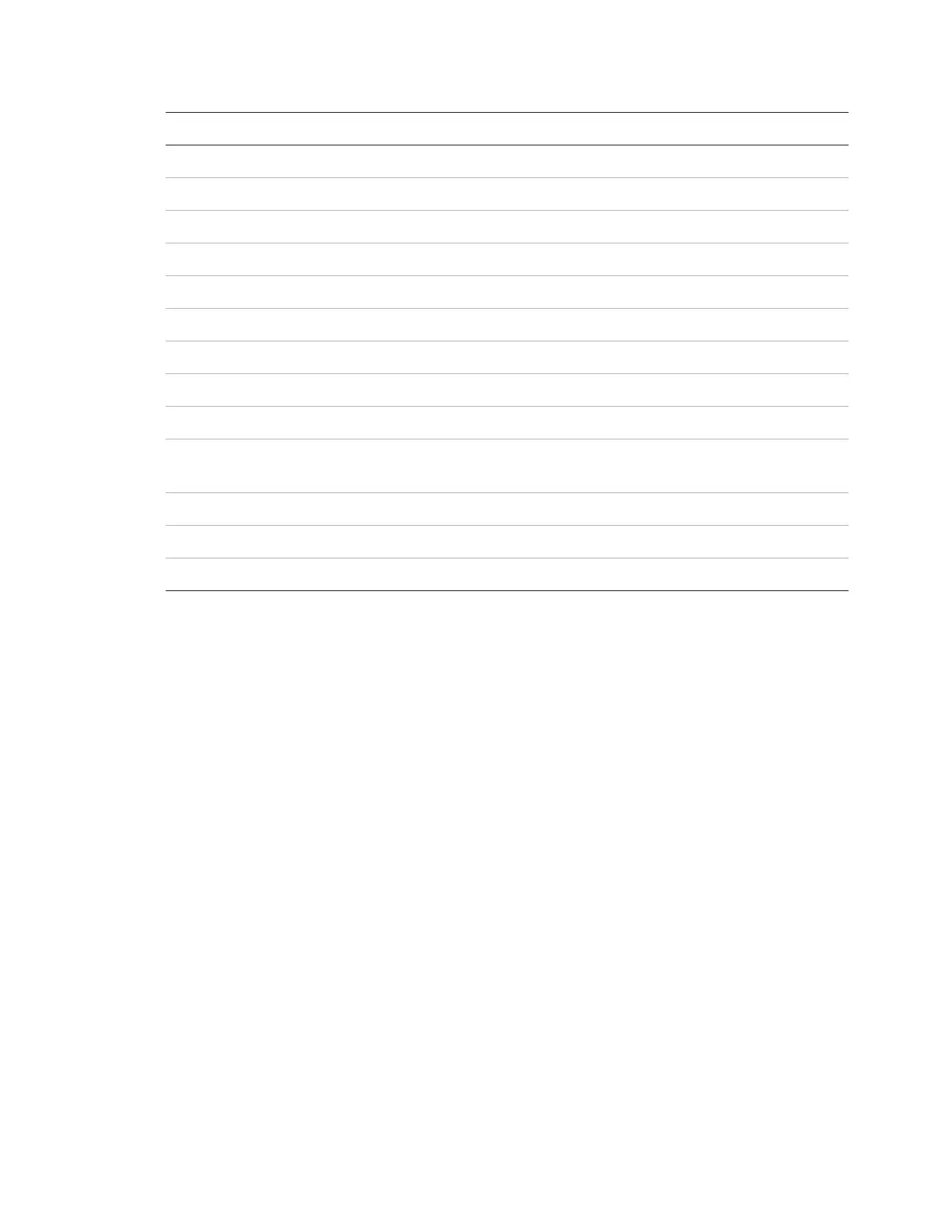

Item Description

11 Nitrogen Bottle

12 Nitrogen Bottle Pressure Gage

13 Regulator Output Pressure Gage

14 Regulator Shut-Off Valve

15 Regulator Output Pressure Valve

16 Nitrogen Supply Hose

17 Input Check Valve

18 Bleed Valve

19 Extension Hose

20 Gage Protector (factory set to limit pressure to the gage to approximately 1.4 MPa

(200 psi)

21 High Pressure Gage—0–21 MPa (0–3000 psi)

22 Low Pressure Gage—0–2.1 MPa (0–300 psi)

23 Chuck Valve

2. With an open-end wrench, turn the locknut counterclockwise on the accumulator valve

assembly to open the valve. Read the pressure on either the high or low accumulator charging

kit pressure gage.

A. If the pressure reading is other than the required pressure level recorded on the

accumulator, continue with the next subsection, “Change the Precharge Pressure”.

B. If the pressure level corresponds to the level recorded on the accumulator label, turn

the locknut clockwise to close the valve and continue this procedure.

3. Open the bleed valve on the accumulator charging kit and remove the chuck valve from the

accumulator. Replace the valve stem cap and protective cover on the accumulator.

Change the Precharge Pressure

Often the precharge of an accumulator mounted on a hydraulic supply line is increased to enhance

system performance and reduce the transient HPS flow demands. Accumulators may be precharged

to 10 MPa (1500 psi) or more, although amounts above 14 MPa (2200 psi) will have less and less

performance effect in most situations. Be sure that you read the following warning before you charge

your accumulator.

Loading...

Loading...