3-CONTROLSANDINSTRUMENTS

Machinelights

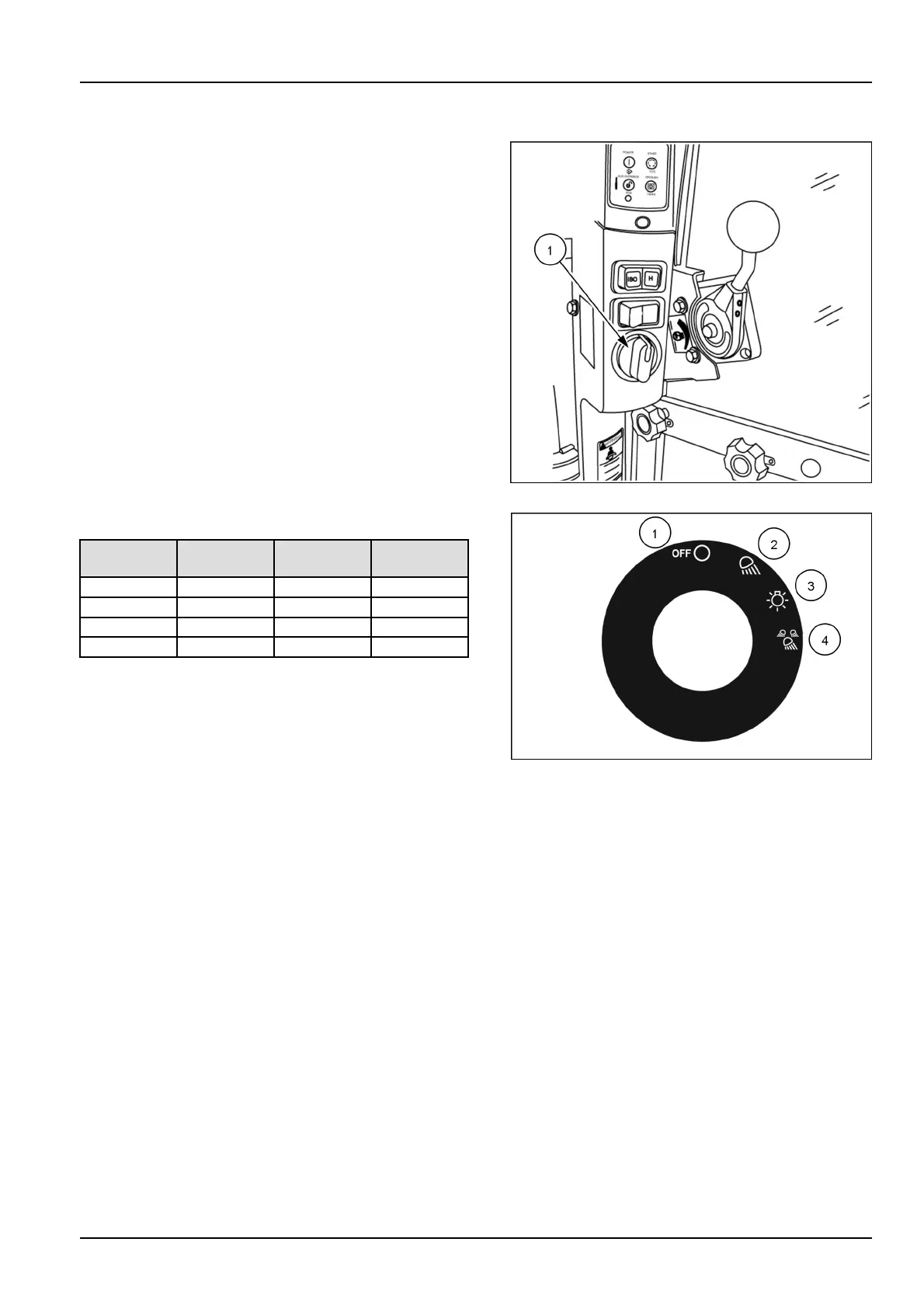

Activatethecabexteriorlights(ifequipped)byarotary

switch(1)onthebottomoftheright-handinstrument

panel.Therotaryswitch(1):

•

remainsinthelastpositionthatyouselect.

•

willnotfunctionwithoutthekey(Machinesequipped

withtheElectronicInstrumentCluster(EIC)).

•

willnotfunctionwithoutthePOWERbuttonengaged

(MachinesequippedwiththeAdvancedInstrument

Cluster(AIC)).

931007504A1

Therotaryswitch(1)hasfourpositions

PositionFrontwork

light

Rearwork

lights

Rearred

lights

(1)OFFOFFOFF

(2)ONONOFF

(3)ONOFFON

(4)ONONOFF

844122902

3-69