2-SAFETYINFORMATION

Loaderarmlockandcabtiltprocedure-radialliftmachines

DANGER

Crushinghazard!

Donotenterorexittheoperator'scompartmentwhiletheloaderarmsareraisedorunsupported.Rest

theloaderarmsonthegroundorverifythatloaderarmisbeingsupportedbytheloaderarmstrutor

loaderarmlockpinbeforeenteringorexitingtheoperator'scompartment.

Failuretocomplywillresultindeathorseriousinjury.

D0168A

DANGER

Crushinghazard!

Theloaderarmisunsupportedduringsupportstrutremoval.Donotenterorexittheoperator'scom-

partmentwithanunsupportedloaderarm.Twopersonsarerequiredduringstorage.Oneperson

shouldremoveandstorethesupportstrutwhiletheoperatorremainsintheoperator'scompartment.

Failuretocomplywillresultindeathorseriousinjury.

D0021B

Raiseandlocktheloaderarmformachineservice

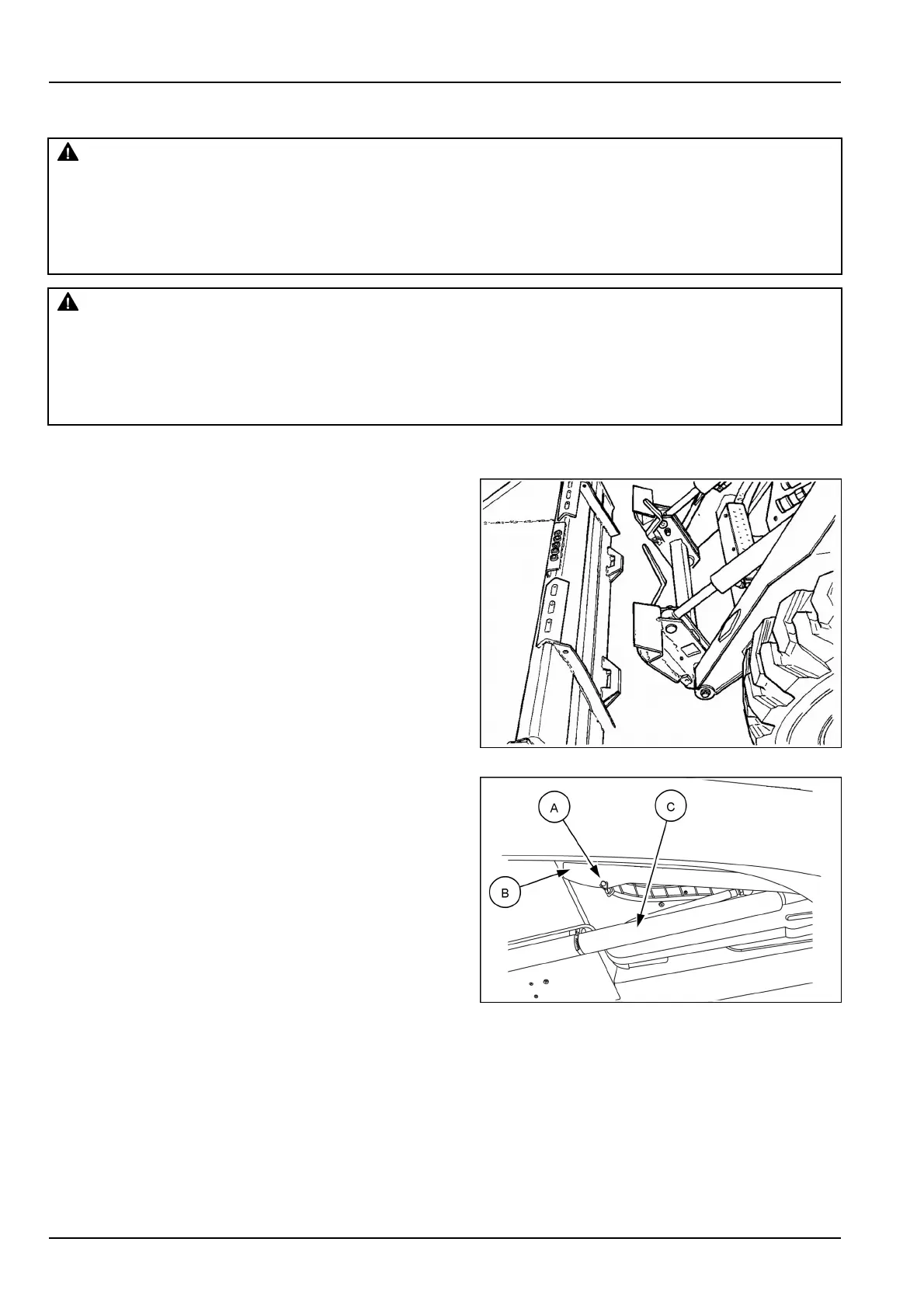

NOTE:Aninstructionaldecalontheinsideoftheright-

handloaderarm,justabovethesupportstrutisalsoavail-

able.Understandtheloaderarmlockprocedurebefore

continuing.

1.Sitintheoperator'sseat,fastentheseatbelt,pullthe

restraintbardown(ifequipped),andstarttheengine.

2.PresstheOPERATEbuttontoenablethehydraulics.

3.Removethebucketorattachmentfromthemounting

plate.

4.Parkthemachineonrmandlevelsurface.

5.Ifanassistantisnotavailable,turnofftheengineand

exitthemachine.

200929241

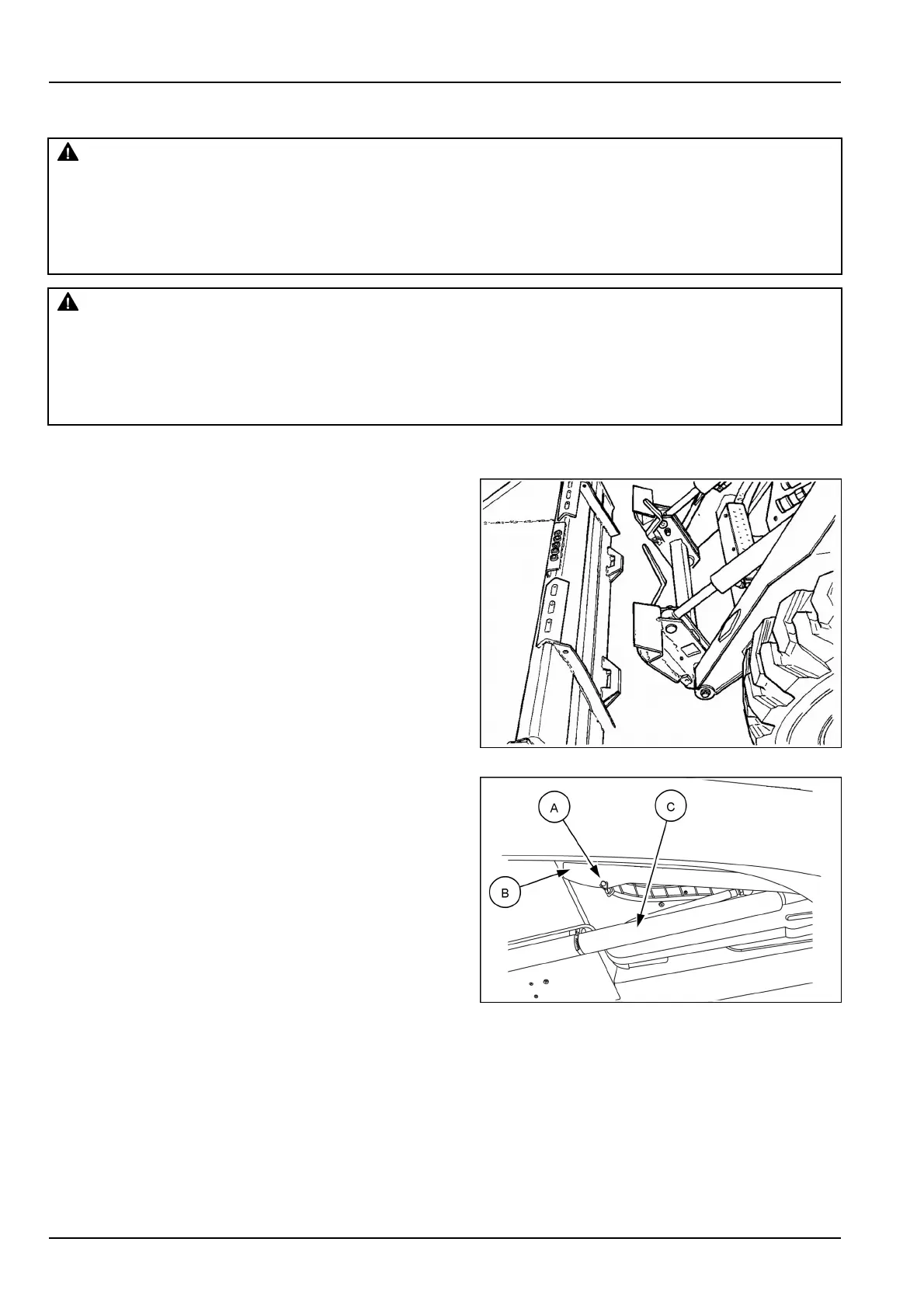

6.Removethesupportstrutpin(A)andletthesupport

strut(B)restontheliftcylinderbarrel(C).

93106848A2

2-18

Loading...

Loading...