4 – ENGLISH

2.1 LIST OF CONSTITUENT PARTS

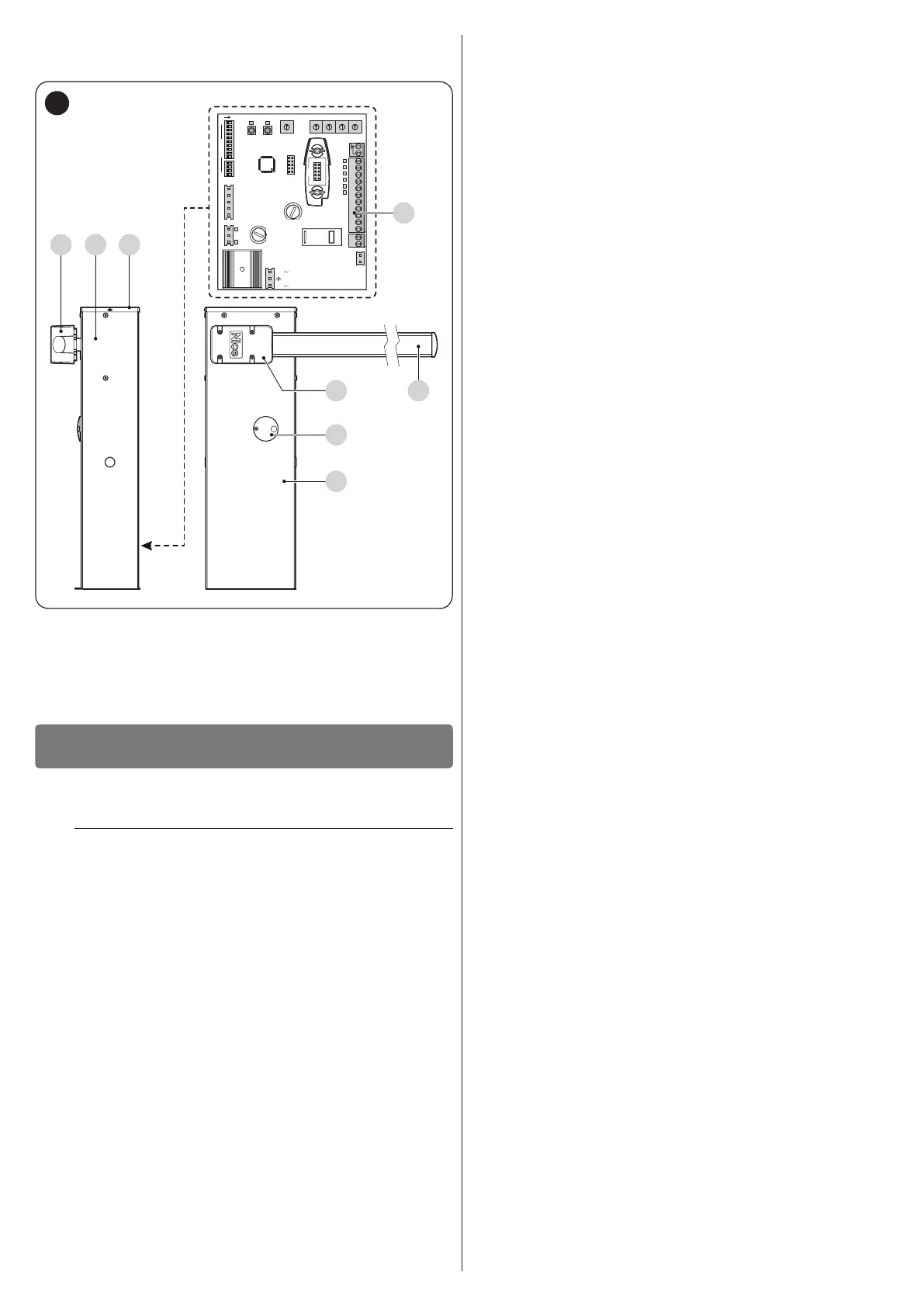

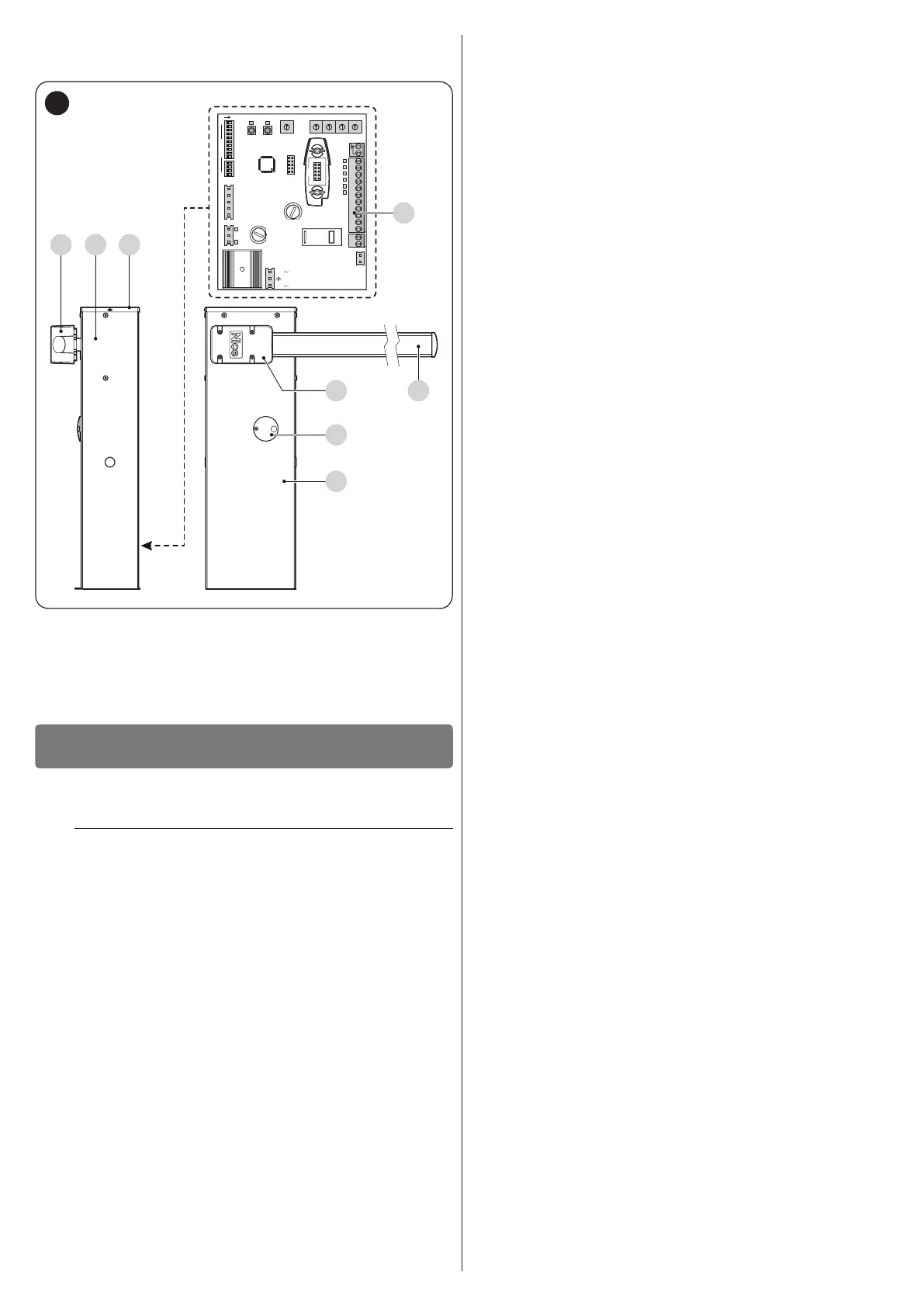

"Figure 1" shows the main parts making up the WIDE.

B CA

EA

B

F

OK RON

Speed- Pause +

PROG RADIO

Fuse F1A

CL

Fuse F8A

3

4

5

6

7

8

9

10

11

12

13

14

15

RX

IBT4N

OP

SbS

PH2

PH

ALT

24V

FCA

FCC

Force LowS. LowF.

SWITCHPS324 114

LIMIT SWITCH

MOTOR

24V

AERIAL

D

1

A Boom support

B Gearmotor containment box

C Cover

D Electronic control and command unit

E Boom

F Locking/unlocking key

INSTALLATION

3

3 INSTALLATION

3.1 PRE-INSTALLATION CHECKS

a

The installation must be carried out by qualied

personnel in compliance with the current legisla-

tion, standards and regulations, and with the in-

structions provided in this manual.

Before proceeding with the product’s installation, it is necessary to:

– check the integrity of the supply

– check that all the materials are in good working order and suited

to the intended use

– check whether it is possible to observe the operating limits spec-

ied in the paragraph “Product usage limits“

– check that the installation location is compatible with the overall

clearance of the product (see “Figure 3“)

– check that the surface chosen for installing the boom gate is

solid and can ensure stable anchorage

– make sure that the installation area is not subject to ooding;

if necessary, the product must be installed appropriately raised

above ground level

– check that the space surrounding the boom gate allows for exe-

cuting the manual manoeuvres easily and safely

– check that there are no obstacles along the boom’s path capable

of hampering the opening and closing manoeuvres

– check that each device to be installed lies in a position that is

protected against the risk of accidental impact.

– verify that the mounting positions of the various devices are pro-

tected against impacts and that the mounting surfaces are suf-

ciently sturdy

– prevent any parts of the automation from being immersed in wa-

ter or other liquids

– keep the product away from heat sources and open ames and

acid, saline or potentially explosive atmospheres; these may

damage the product and cause malfunctions or dangerous sit-

uations

– connect the control unit to an electricity supply line equipped

with a safety earthing system

3.2 PRODUCT USAGE LIMITS

Before proceeding with the product’s installation, it is necessary to:

– check that all the values appearing in the “TECHNICAL SPECI-

FICATIONS” chapter are compatible with the intended use

– check that the estimated durability (refer to the paragraph “

Product durability”) is compatible with the intended use

– check that all limitations, conditions and warnings appearing in

this manual can be fully observed.

3.2.1 Product durability

The product’s durability is its average economic life value and is

strongly inuenced by the degree of severity of the manoeuvres: in

other words, the sum of all factors that contribute to product wear.

To estimate the durability of your automated device, proceed as

follows:

1. add the values of the items in "Table 2" relative to the sys-

tem’s conditions

2. in the graph shown in "Figure 2", from the value obtained

above, trace a vertical line until it intersects the curve; then,

trace a horizontal line until it intersects the line of the "ma-

noeuvre cycles". The value obtained is the estimated lifetime

of your product.

The durability values shown in the graph can only be obtained if the

maintenance schedule is strictly observed – see the “PRODUCT

MAINTENANCE” chapter. The durability is estimated on the basis

of the design calculations and the results of tests effected on pro-

totypes. Being an estimate, therefore, it offers no explicit guarantee

of the product’s actual useful life.

Example of durability calculation: WIDE M with mobile sup-

port, jointed boom

"Table 2" shows the "severity indices" for this type of installation:

15% ("mobile support"), 15% ("jointed boom").

These indicators must be added together to obtain the overall se-

verity index, which in this case is 30%. With the value calculated

(30%), identify along the graph’s horizontal axis (“severity index”)

the value corresponding to the number of “manoeuvre cycles” that

the product can perform throughout its lifetime = roughly 200.000

cycles.

Loading...

Loading...