48 - FORM NO. 56043107 - Advolution

™

2710

/ UHR 70-1700

ELECTRICAL SYSTEM

FUNCTIONAL OVERVIEW OF MAIN CONTROL BOARD

The primary function of the main control board A1 is to position the burnishing pad with respect to the fl oor surface using a lift actuator motor to

maintain the correct pad pressure and current draw of the pad motor. When the pad drive switch (EE) is depressed this will lower the pad deck to

the operating position and by activating the drive pedal start the pad motor. The controller is continuously monitoring the current to the pad motor

and when it senses a current draw out of the desired range it automatically raises or lowers the pad deck by turning on the pad lift actuator motor.

This process is repeated until the pad motor is shut off. The controller also manages the other supportive systems such as the optional active dust

control. Note: See the Know Your Machine section in this manual for a complete explanation of the machine’s operation.

The secondary function of the main control box is to detect any system failures and display an error code on the display panel or store it in the

main control board’s recall memory mode. The error code(s) are used to help the service person determine the fault and to quickly guide in

repairing a specifi c system malfunction. Note: See the Troubleshooting Guide for further information. An additional special feature of the main

control board is to change program settings for a set of specifi c machine functions. See the Main Control Board Special Program Options section

in this manual for further information.

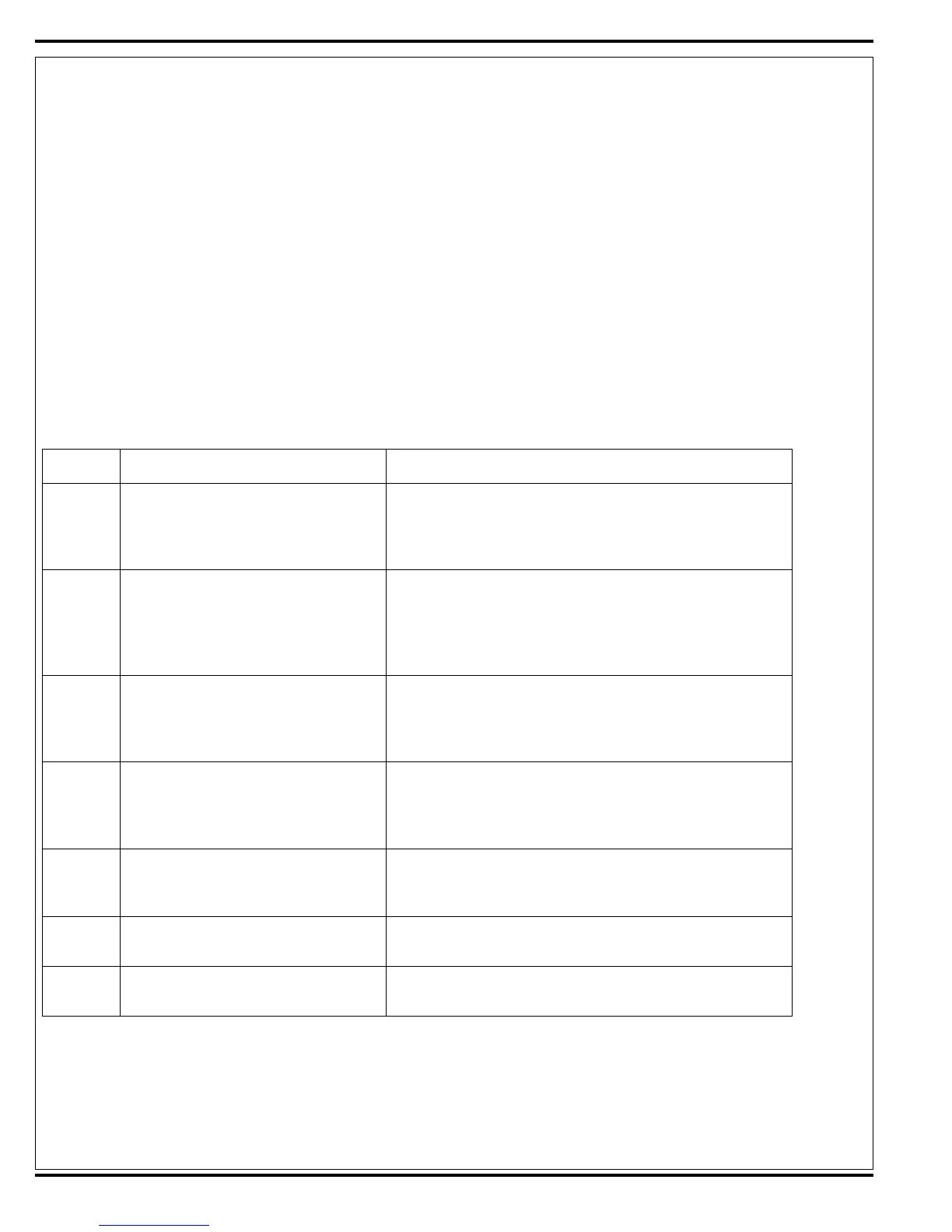

TROUBLESHOOTING GUIDE

Any error codes detected by main control board will be displayed on the display panel (CC) as they occur. If more than one-error exists the display

will sequence through the error codes at one-second intervals. The error will display as “Err” followed by a two-digit code. EX: Err 06 would be a

Pad Motor Overload.

MAIN CONTROLLER ERROR CODES

Display

Code

Fault Description Troubleshooting Action

Err 02 Accessory Circuit Overload Check for a short circuit in the LP5 headlight and LP6 fl ashing

warning beacon accessory systems wiring and components. SVR

Tip: Disconnect each component separately and observe if the code

goes away then check that specifi c component. Repair or replace

defective part or wiring.

Err 03 Speed control System Faults 1. Check for a tripped 40Amp (CB2) breaker and reset if needed. 2.

Next investigate the reason for the mechanical overload. Examples

prolonged ramp climbing, exceeding the machines grad ability limit

and the electric parking brake not releasing. 3. Then see Curtis drive

motor controller section to further troubleshoot the drive system

(table 1).

Err 04 Pad Deck Lift Actuator Motor Overload

Note: Normal current load is1-2.5 Amps,

Max. current load 6 Amps & Max. current no

load 1.4 Amps.

1. Check for binding or frozen lift linkage and excessive weight on

burnishing deck. 2. Perform a current draw test. To test disconnect

the motor plug and attach the actuator test cord (P.N. 56407502) and

compare readings to the fault description table to the left. 3. Test for

short circuits in the actuator motor and wiring. Repair or replace.

Err 06 Pad Motor Overload

Note: See Table #2 burnishing pad pressure

settings in the Pad Pressure Programming

section for detailed load current values for

the three different pressure settings.

1. Check for mechanical binding in the rotation of the pad motor and

also improper pad pressure lift motor operation. 2. check for an open

circuit in the small Black/Yellow pad motor current sense wire and

repair wire if open. 3. Check for short circuit in pad motor or wiring.

Repair or replace.

Err 08 Pad Motor Contactor Coil Open

Note: Coil resistance spec is 120 Ohms

plus or minus 10%.

1. Check for an open circuit in the coil wiring (wire colors Black/White

& Blue/White). 2. Test coil winding resistance, for an open circuit.

Replace if defective. 3. Check controller coil output voltage for 36V if

0V controller failure replace.

Err 17 Pad Lift Actuator Motor Open 1. Check for disconnected actuator wiring, open in wiring or defective

actuator motor. Repair or replace. 2. Check controller actuator output

voltage for 36V if 0V main controller failure (replace).

Err 21 Pad Motor Open 1. Check for open circuits in the pad motor and wiring. Repair or

replace. 2. Test for 36V at the K1 load contact output (red wire #2)

with its coil energized if 0V replace the K1 contactor.

Loading...

Loading...