8 - FORM NO. 56043107 - Advolution

™

2710

/ UHR 70-1700

MAINTENANCE SCHEDULE

MAINTENANCE ITEM Daily Weekly Monthly Yearly

Charge Batteries X

Check/Clean/Replace Burnishing Pad X

Check/Replace Dust Collection Bag X

Check Battery Water Level(s) X

Check/Replace Pad Shroud Skirt X

Chain Tension - Steering X

Lubrication - Grease Fittings X

Check Carbon Brush Wear On Pad/Drive/Vacuum Motors X

Note: See the individual machine system sections for maintenance information.

* Have Nilfi sk-Advance check the vacuum motor carbon motor brushes once a year or after 300 operating hours. The pad and drive motor carbon

brushes check every 500 hours or once a year.

WARNING!

Turn the key switch off and disconnect the batteries before servicing the machine.

* Check vacuum motor carbon brushes (Qty 2) once a year or after 300 operating hours.

* Check pad and wheel drive motor(s) carbon brushes (Qty 4 per motor) once a year or after 500 operating hours.

* The original (new) length of each carbon brush is 1-3/32” (27.76mm) on all 36 volt machine models brush and wheel drive motors.

* All motors: Replace carbon brushes when shorter than 3/8” (9.5mm) to obtain the same motor effi ciency as new brushes.

IMPORTANT!

Motor damage resulting from failure to service the carbon brushes is not covered under warranty. See the Limited Warranty

Statement.

BATTERIES AND CHARGERS

Attention: See the ELECTRICAL SYSTEM section for battery installation, battery maintenance and charger system requirements.

LUBRICATING THE MACHINE

Locations requiring periodic oiling are:

Qty 1 - Steering Wheel Shaft Universal Joint (oil hole or port)

TOWING THE MACHINE

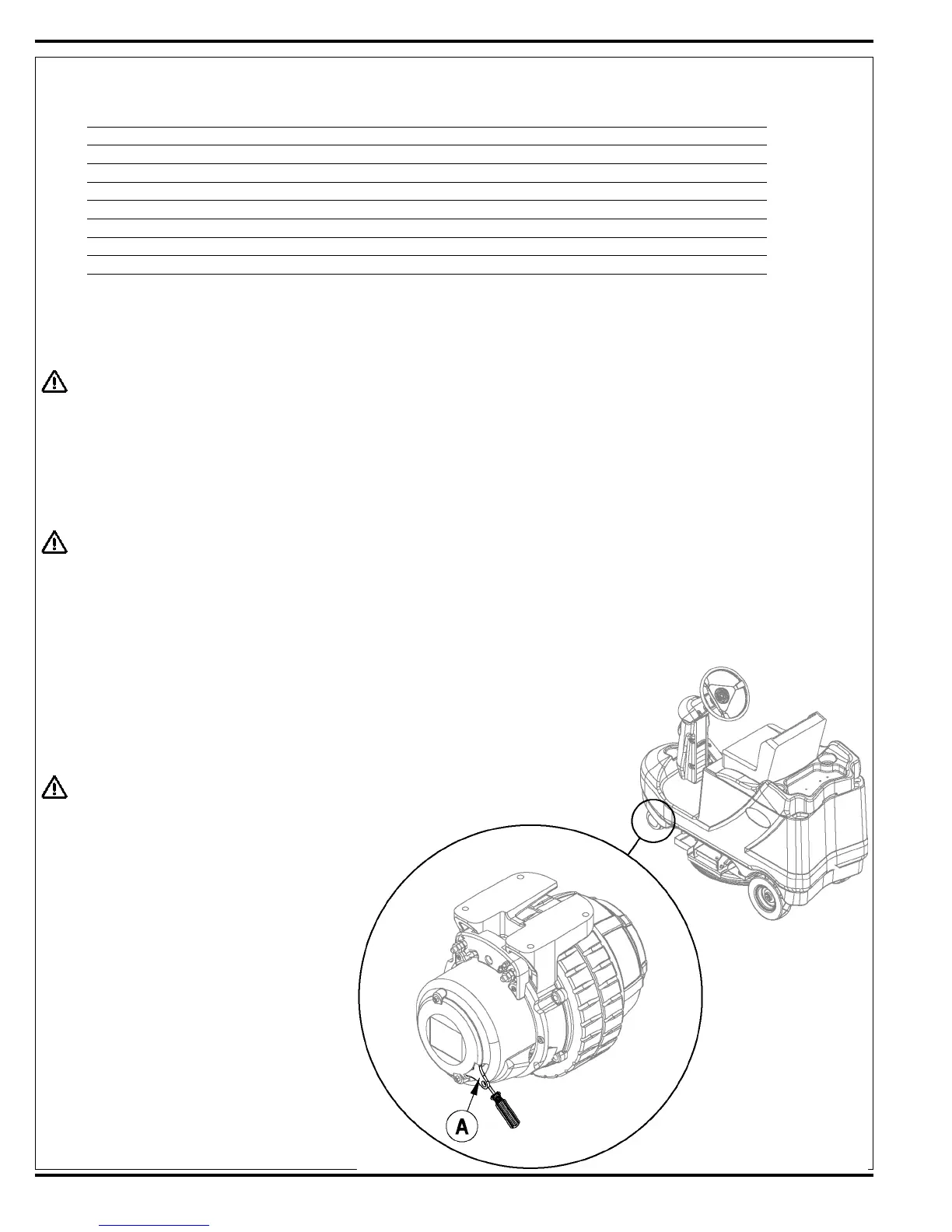

CAUTION!

The Drive / Steer Wheel Assembly (14) has a built in

electromagnetic brake that is engaged whenever the

Master Key Switch (AA) is OFF or the FWD / REV Drive

Pedal (8) is in the neutral position. This brake can be

manually over ridden if necessary by inserting a medium

to large screwdriver behind the Yoke (A) as shown. This

should only be done in the event you need to push or pull

the unit.

Loading...

Loading...