11.2 Inspection and maintenance

11.2.1 Service and inspection intervals

Description

To avoid motor faults, perform maintenance work, inspections and overhauls at regular

intervals.

Note

Inspection if there are faults or unusual conditions

Unusual conditions or faults that represent overstressing of the motor, e.g. overload or short-

circuit, can result in consequential damage to the machine.

Immediately perform an inspection when faults or exceptional conditions occur.

Maintenance measures, inspection/maintenance times intervals

The maintenance intervals depend on the operating conditions.

• Adapt the maintenance intervals to match the local conditions, such as pollution/dirt,

switching frequency, load, etc.

• Perform the following maintenance measures as specied in the table.

NOTICE

Improper maintenance

Service and maintenance must only be performed by properly authorized qualied personnel.

Use original Siemens parts only.

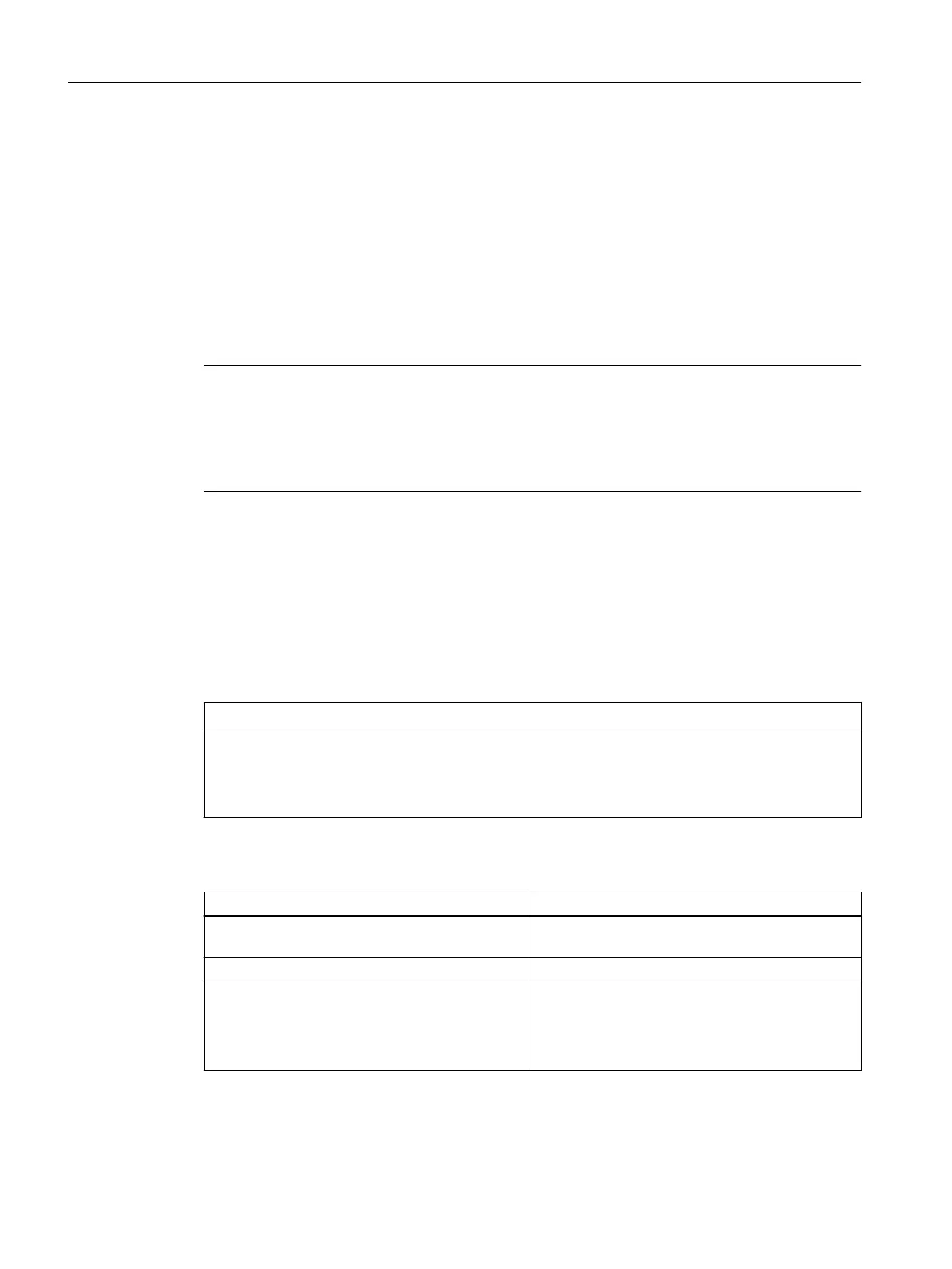

Table 11-1 Maintenance measures after operating times or intervals

Machine operation times and intervals Measure

As required Monitor and check the motor for unusual noises,

vibrations and changes

If required or after 25000operating hours Check radial shaft seal ring and replace if worn.

If required or after 25000operating hours For 1F☐2☐03 ... 1F☐2☐05 motors:

Replace motor if necessary.

For 1F☐2☐06 ... 1F☐2☐10 motors:

Check motor bearing and replace if necessary.

The maintenance and repair of the motor can be performed in authorized Siemens Service

Centers all over the world.

Maintenance

11.2Inspection and maintenance

SIMOTICS S-1FT2 synchronous motors for SINAMICS S120

108 Operating Instructions, 12/2023, A5E50610821B AF

Loading...

Loading...