Motor shaft sealing

The motors are sealed dierently to achieve degrees of protection according to IEC60034-5.

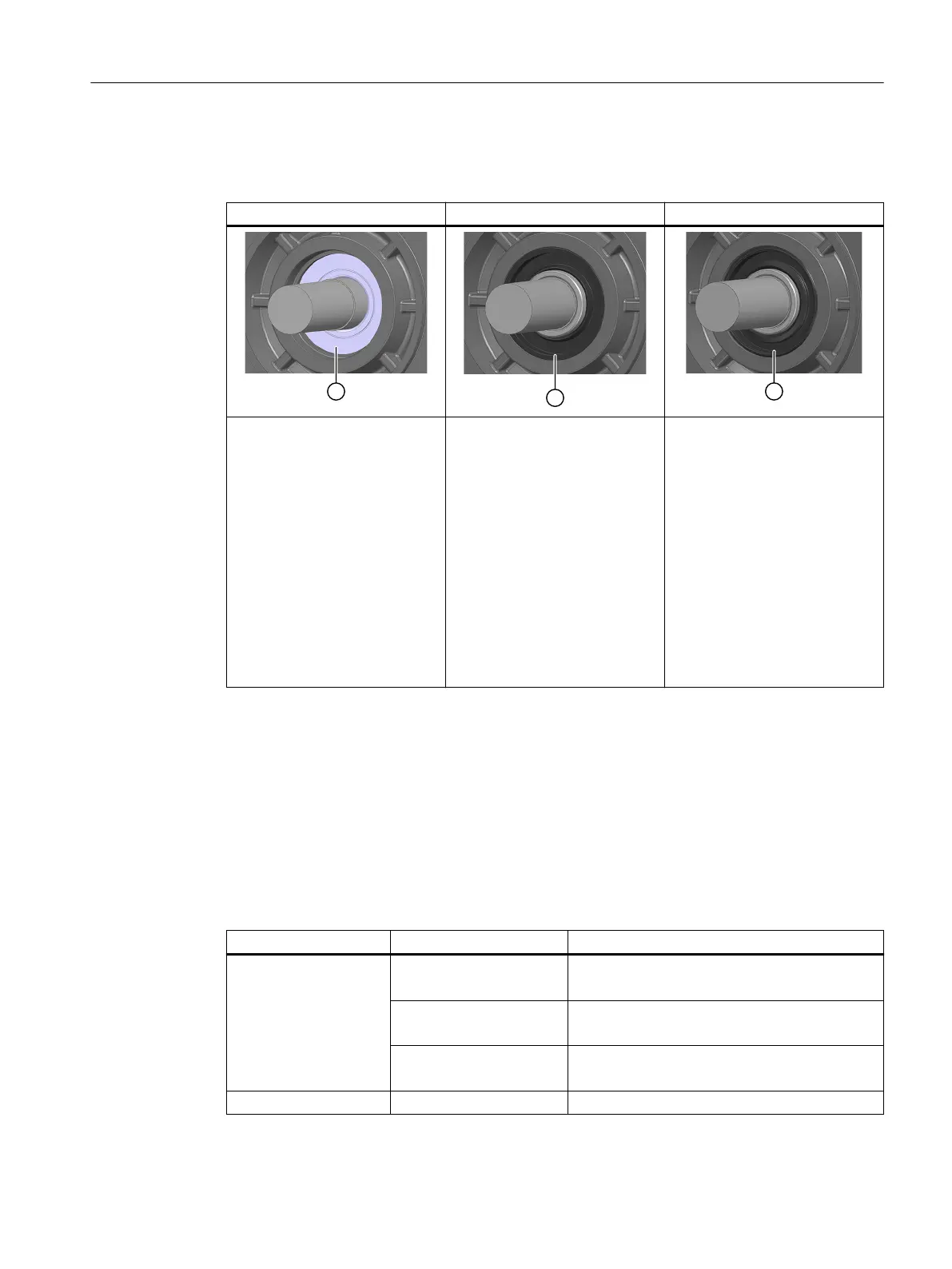

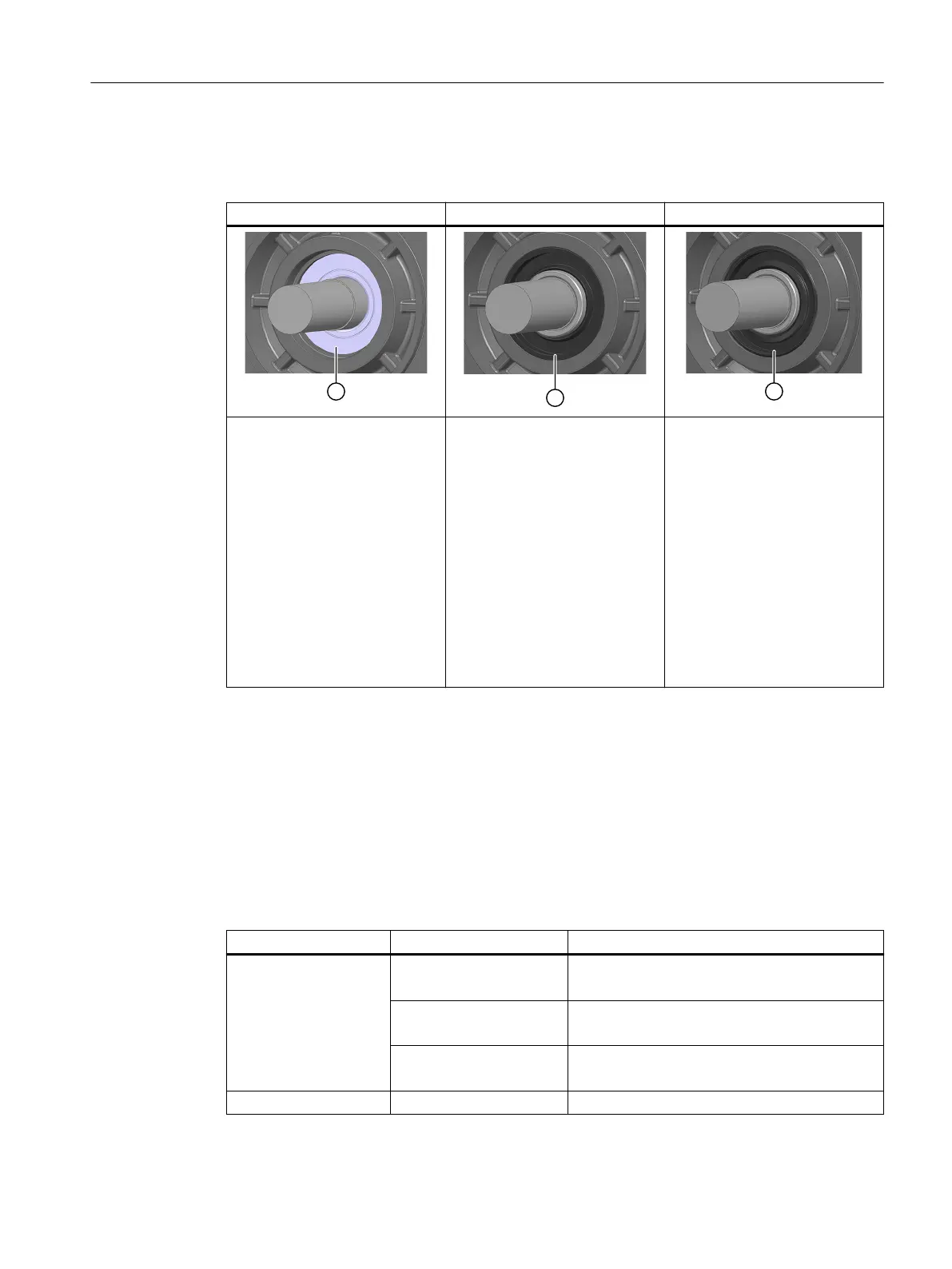

IP64 IP65 IP67

① Ball bearing with sealing

washers

Moisture in the area around the

shaft and the ange is not per‐

missible.

Note:

For IP64, it is not permissible that

liquid collects in the ange.

① Radial shaft sealing ring with‐

out annular spring

Sealing of the shaft outlet

against splashwater and/or cool‐

ing-lubricating medium. Dry run‐

ning of the radial shaft sealing

ring is permissible. Service life

approx. 25000h (guide value).

With degree of protection IP65, it

is not permissible for liquid to col‐

lect in the ange.

① Radial shaft sealing ring

For gearbox mounting (for gear‐

boxes that are not sealed) to seal

against oil.

The sealing lip must be adequate‐

ly cooled and lubricated by the

gearbox oil in order to guarantee

reliable function.

Service life approx.10000h

(guide value).

If a radial shaft sealing ring runs

dry, then this has a signicant

negative impact on the function‐

ality and the service life.

More information is provided in Chapter "Shaft extension (Page42)".

3.1.5 Noise emission

Sound pressure level

When operated in the speed range 0 to rated speed, 1FT2 motors can reach the following

enveloping surface sound pressure levels L

p

.

Cooling method Frame size Enveloping surface sound pressure level L

p

Naturally cooled 1FT2☐03

1FT2☐04

55dB (A) + 3 dB tolerance

1FT2☐05

1FT2☐06

65dB (A) + 3 dB tolerance

1FT2☐08

1FT2☐10

70dB (A) + 3 dB tolerance

Force-ventilated 1FT2☐08 73dB (A) + 3 dB tolerance

Description of the motors

3.1Technical characteristics and ambient conditions

SIMOTICS S-1FT2 synchronous motors for SINAMICS S120

Operating Instructions, 12/2023, A5E50610821B AF 31

Loading...

Loading...