mmmmm

Remote Operation : PA

Page 30 SITRANS Probe LU (PROFIBUS PA) – INSTRUCTION MANUAL 7ML19985JB02

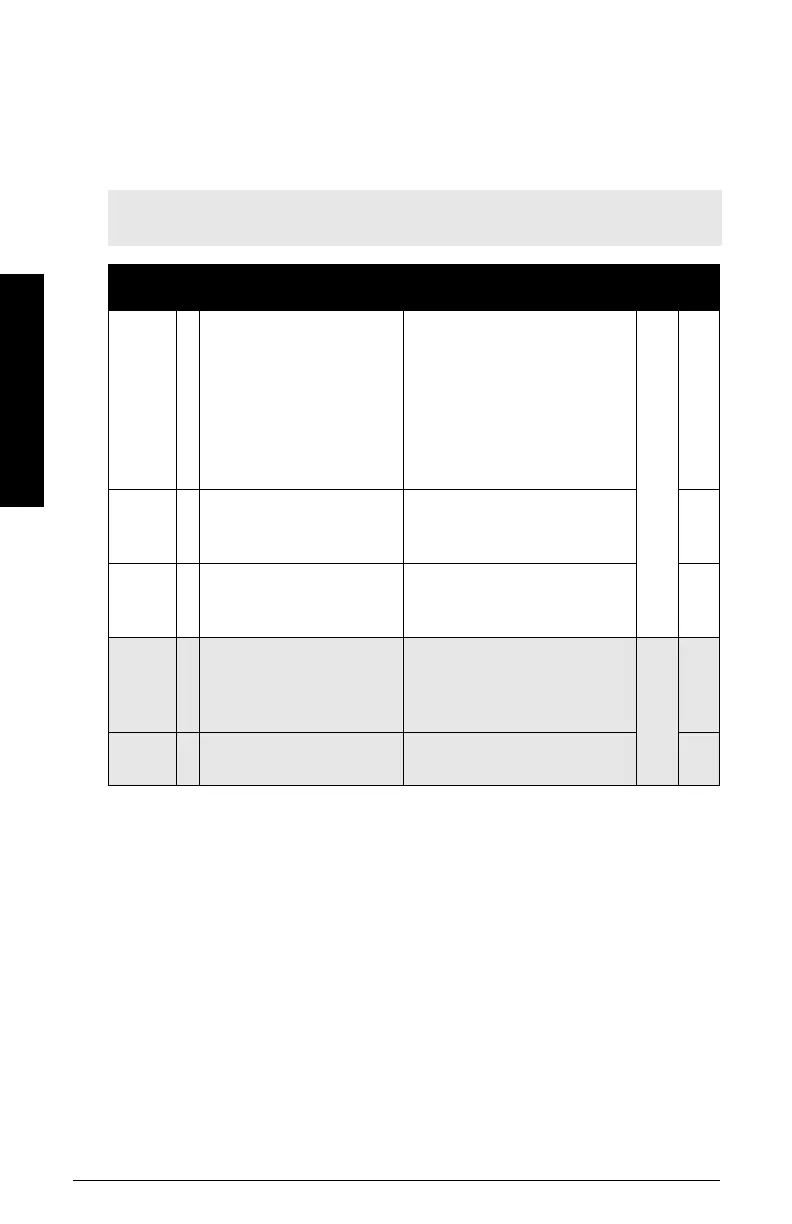

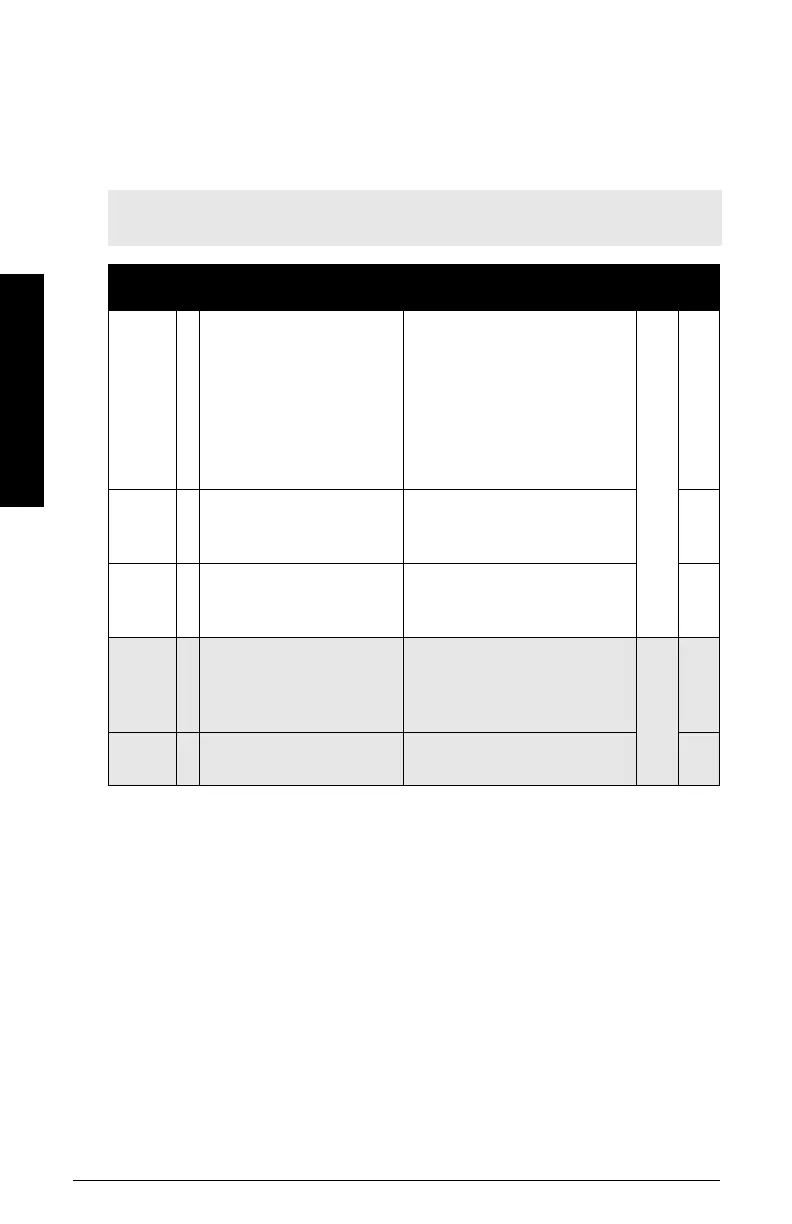

Acyclic Extended Diagnostics (General Fault Codes)

In addition to the extended diagnostics available by cyclic data exchange (shown above),

further extended diagnostics are available via acyclic communications. This consists of

six bytes. Please see

Appendix G: Asynchronous Communications Data Map

on page 61

for the location of the Extended Diagnostics.

Note: Certain fault codes (identified by an asterisk [*] in the table below) will persist

until a manual reset has been performed (see

Reset Fault

on page 74).

LCD

display

Cause/symptom Corrective Action Byte Bit

S:0

Device unable to get a mea-

surement within the Fail-

safe timer period. Possible

causes: faulty installation,

material buildup, foaming/

other adverse process con-

ditions, invalid calibration

range.

Ensure installation details are

correct; ensure no material

buildup; adjust process condi-

tions to minimize foam or other

adverse conditions; correct

range calibration. If fault persist,

contact your local Siemens rep-

resentative.

0

0

S:1 Broken internal HF cable.

Reset power. If fault persists,

contact your local Siemens rep-

resentative: repair required.

1

S:2

No power supply to

technology board.

Reset power. If fault persists,

contact your local Siemens rep-

resentative: repair required.

2

S:10

Input parameters High Cali-

bration Point and Low Cali-

bration Point are the same.

Check calibration settings of

device. Ensure settings for High

Calibration Point and Low Cali-

bration Point are different.

1

3

S:11

Internal temperature sen-

sor has failed.

Repair required: contact your

local Siemens representative.

4

Loading...

Loading...