FUEL SYSTEM 4-19

CARBURETOR CLEANING

"

Some carburetor cleaning chemicals, especially dip-type

soaking solutions, are very corrosive and must be

handled carefully. Always follow the chemical

manufacturer’s instructions on proper use, handling and

storage.

• Clean all jets with a spray-type carburetor cleaner and dry them

using compressed air.

• Clean all circuits of the carburetor thoroughly – not just the

perceived problem area. Clean the circuits in the carburetor

body with a spray-type cleaner and allow each circuit to soak, if

necessary, to loosen dirt and varnish. Blow the body dry using

compressed air.

%

Do not use a wire to clean the jets or passageways. A

wire can damage the jets and passageways. If the com-

ponents cannot be cleaned with a spray cleaner it may

be necessary to use a dip-type cleaning solution and al-

low them to soak. Always follow the chemical

manufacturer’s instructions for proper use and cleaning

of the carburetor components.

• After cleaning, reassemble the carburetor with new seals and

gaskets.

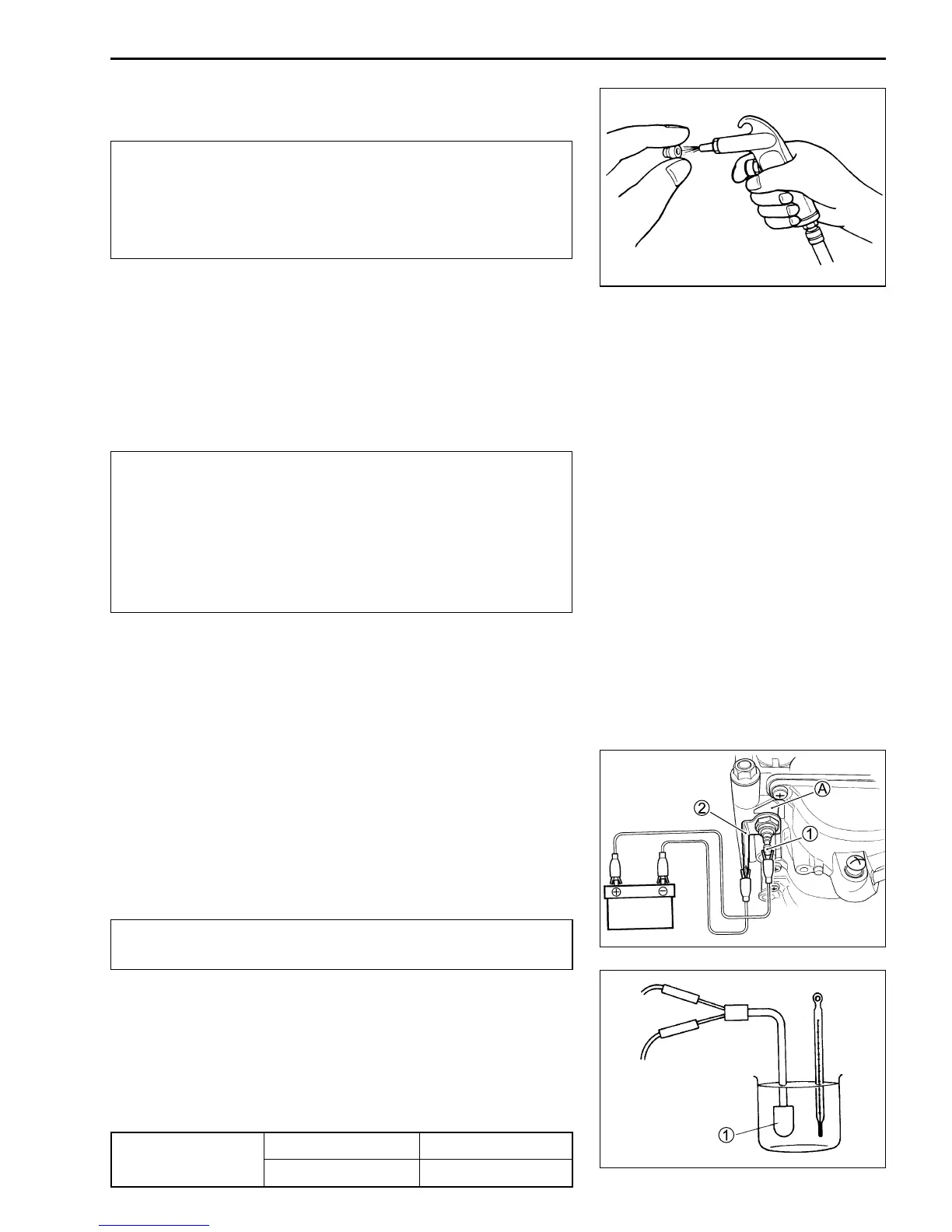

CARBURETOR HEATER INSPECTION

(Only for E-02)

• Remove the carburetor assembly. (!4-14)

• Disconnect the carburetor heater terminal lead wires.

• Connect the positive

+

terminal of a 12V battery to the termi-

nal 1 of the carburetor heater and the battery negative

-

ter-

minal to the terminal 2.

• Check that the heater section A is heated in 5 minutes after

the battery has been connected. If the carburetor heater is not

heated up, replace the carburetor heater with a new one.

"

Do not touch the carburetor heater directly to prevent

burn.

THERMO-SWITCH INSPECTION

(Only for E-02)

• Cool the thermo-switch 1 with ice water and check for continu-

ity.

& 09900-25008: Multi-circuit tester

'

Thermo-switch

Below 8 – 14°CYes

continuity

Above 15 – 21°CNo

Loading...

Loading...