InspectingtheSteeringand

SuspensionComponents

ServiceInterval:Every100hours—Inspectthe

steeringandsuspensionforloose

ordamagedcomponents.

Withthesteeringwheelatthecenteredposition

(Figure44),turnthesteeringwheeltotheleftorright.

Ifyouturnthesteeringwheelmorethan13mm(1/2

inch)totheleftorright,andthetiresdonotturn,check

thefollowingsteeringandsuspensioncomponentsto

ensurethattheyarenotlooseordamaged:

•Steeringshafttothesteering-rackassemblyjoint

Important:Inspecttheconditionandsecurity

ofthepinion-shaftseal(Figure45).

•Steering-rackassemblytierods

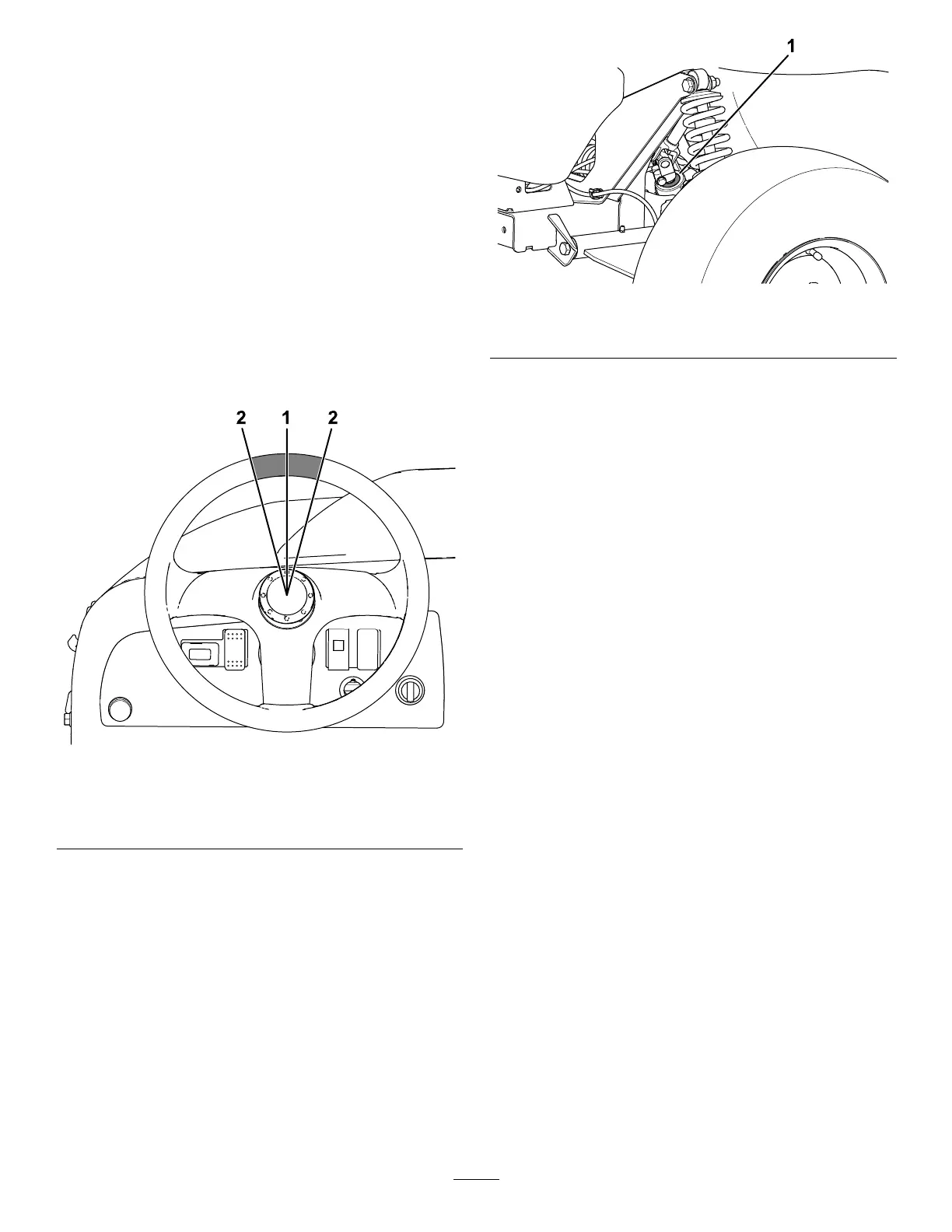

g313199

Figure44

1.Steeringwheelatthe

centeredposition

2.13mm(1/2inch)from

thecenterofthesteering

wheel

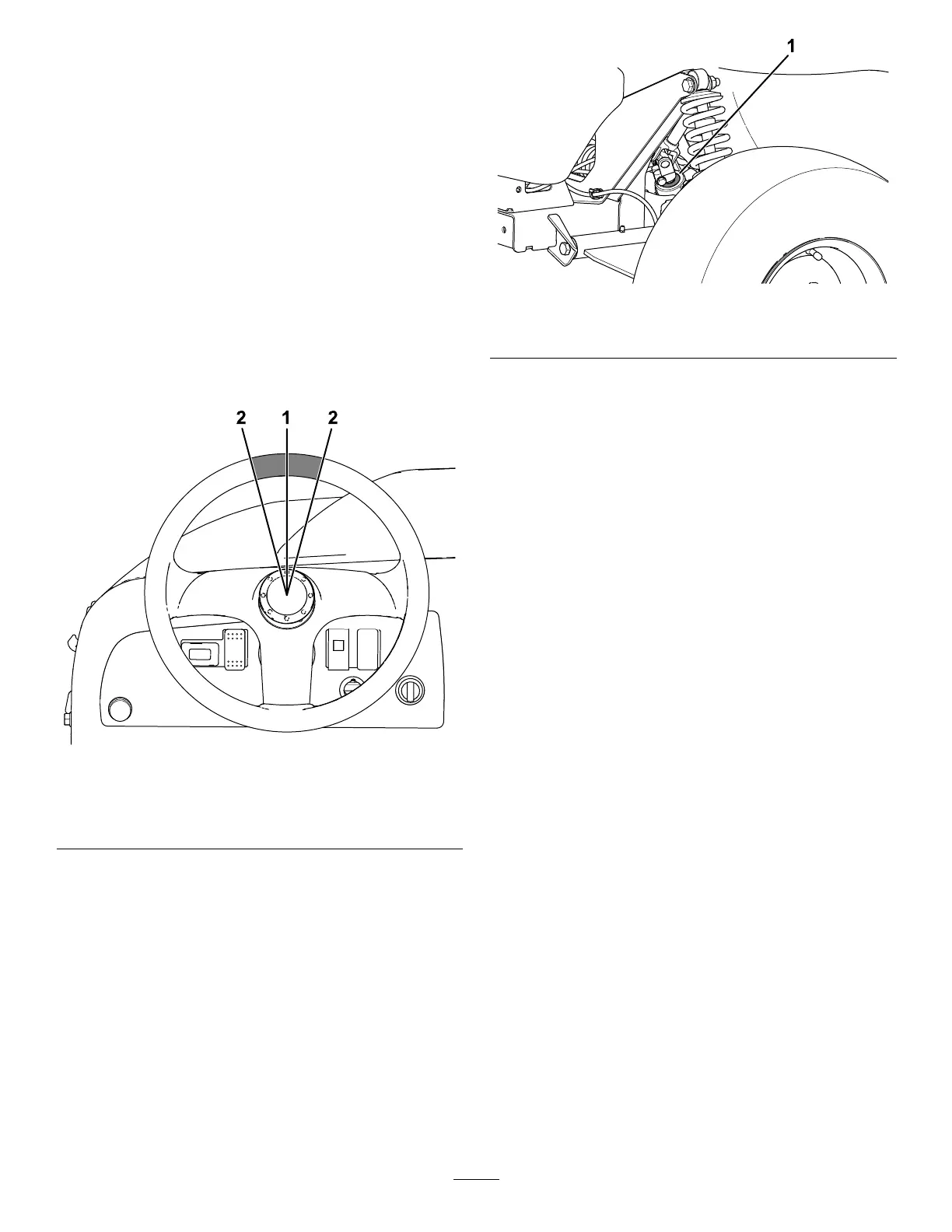

g313201

Figure45

1.Pinion-shaftseal

AdjustingtheFrontWheel

Toe-inandCamber

ServiceInterval:Every100hours/Yearly(whichever

comesrst)—Checkthefrontwheel

toe-inandcamber.

Important:YouwillneedtoobtainToroPartNo.

132-5069fromyourToroDistributortoperform

thisprocedure.

Thetoe-inshouldbe0to6mm(0to1/4inch).

•Checkthetirepressuretoensurethatthefront

tiresareinatedto82kPa(12psi).

•Either,addweighttothedriver'sseatequaltothe

averageoperatorwhowillrunthemachine,or

haveanoperatorsitontheseat.Theweightor

operatormustremainontheseatfortheduration

oftheprocedure.

•Onalevelsurface,rollthemachinestraightback

2to3m(6to10ft)andthenstraightforward

totheoriginalstartingposition.Thisallowsthe

suspensiontosettleintotheoperatingposition.

•Measurethetoe-inwiththewheelsfacingstraight

ahead.

1.UsingtoolT oroPartNo.132-5069,rotatethe

collarontheshockabsorbertochangethe

lengthofthespring(Figure46).

Note:Makethecamberadjustmentsonlyif

youareusingafrontattachmentorifthereis

uneventirewear.

42

Loading...

Loading...