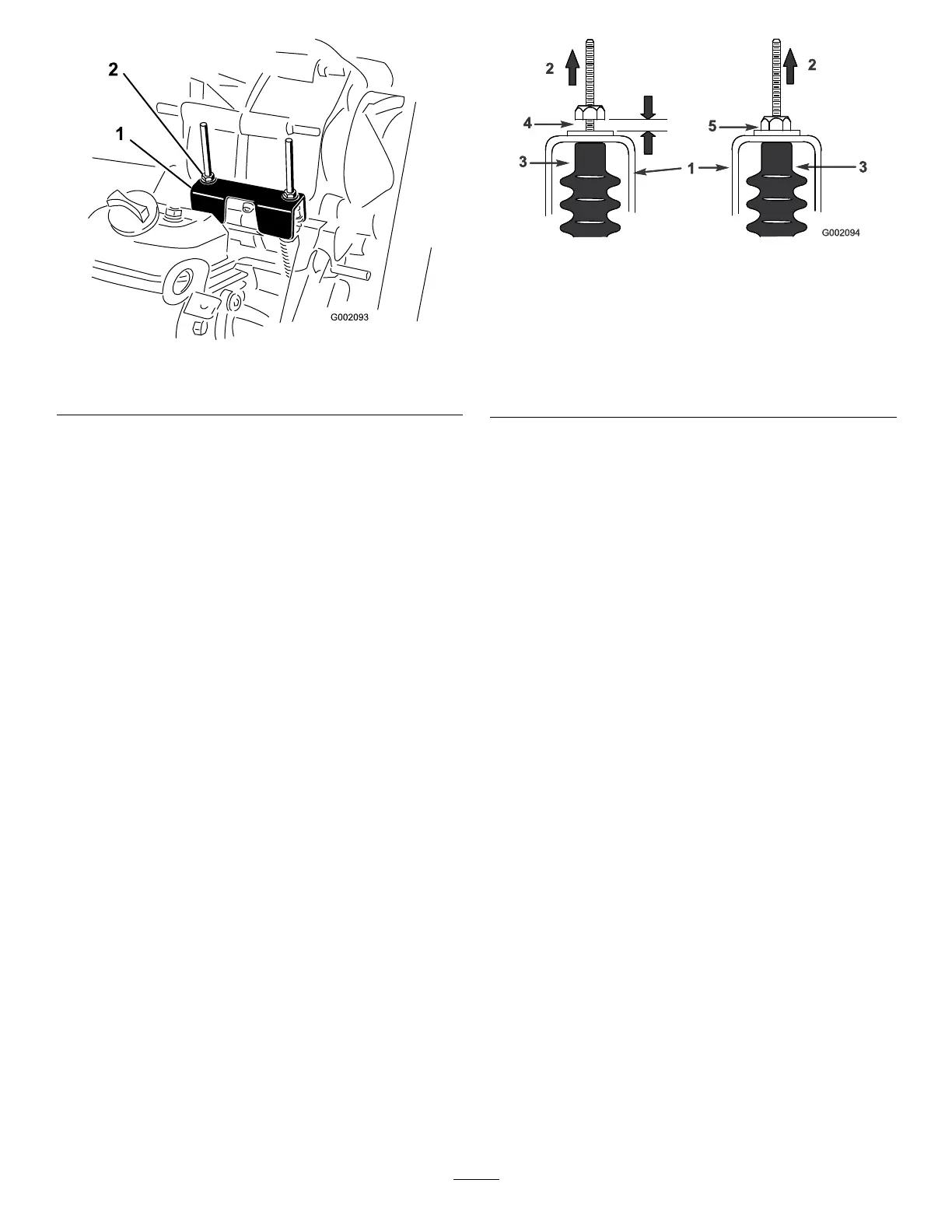

g002093

Figure52

1.Neutralbracket2.Locknuts

3.Rotateoneofthelocknuts(Figure52)toachieve

a0.762to1.524mm(0.030to0.060inch)gap

betweenthebottomofthenut/washerandthe

neutralbracket.

Note:Youmustholdthethreadedshaftbelow

thebracketwhenadjustingthelocknutposition

ontop.

4.Rotatetheotherlocknuttoachievea0.76

to1.52mm(0.03to0.06inch)gapbetween

thebottomofthenut/washerandtheneutral

bracket.

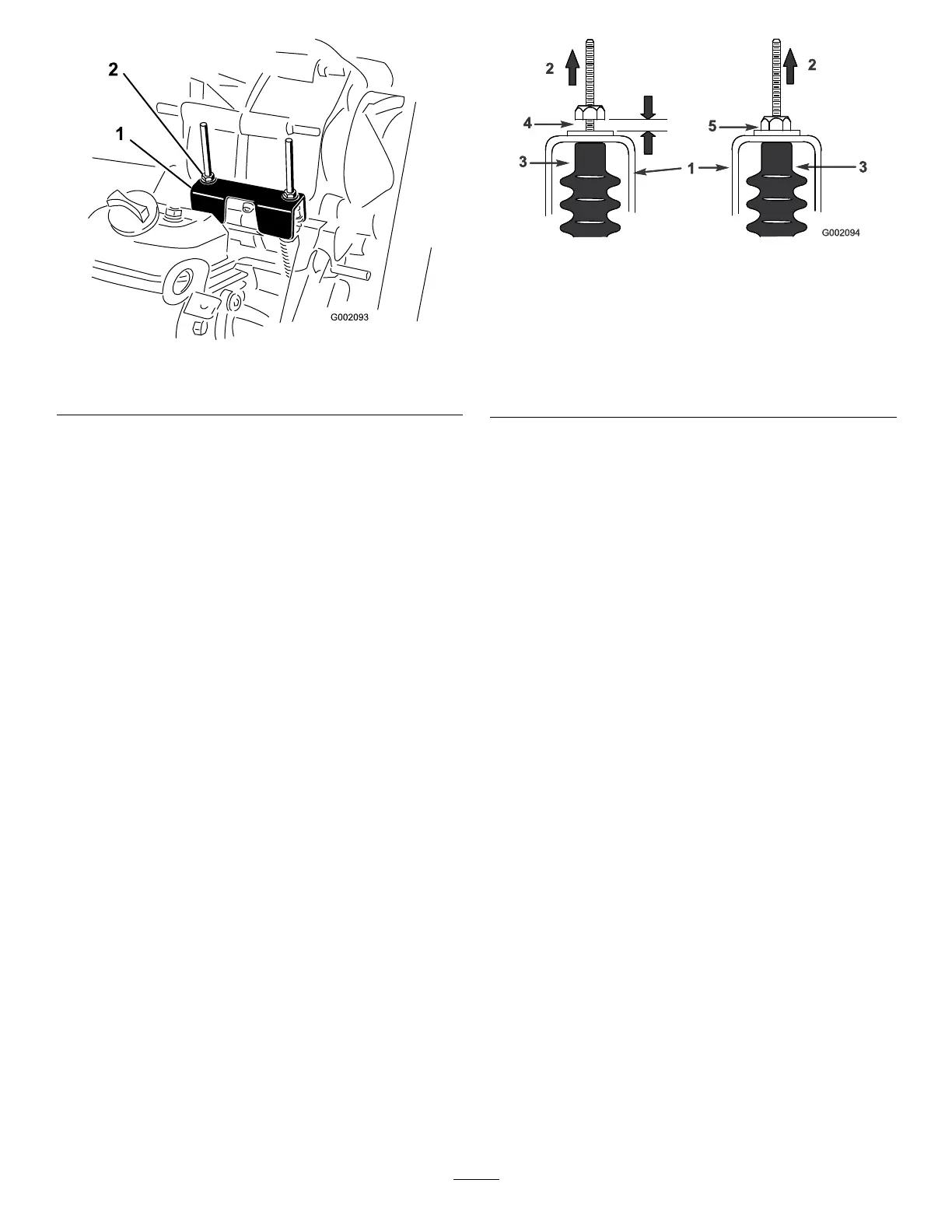

5.Pulluponeachshiftcableanensurethatthere

isa0.76to1.52mm(0.03to0.06inch)between

thenut/washerandtheneutralbracket(Figure

53).

Note:Ifthereisanotagap,adjustthenutsto

achievethespeciedgap.

g002094

Figure53

1.Neutralbracket

4.0.76to1.52mm(0.03to

0.06inch)gap

2.Pullup5.Wrong—adjusttheto

achieveagapof0.76to

1.52mm(0.03to0.06

inch)inch

3.Cableboot

6.StarttheengineandshiftintoFORWARD,

REVERSE,andNEUTRALseveraltimestoensure

thattheneutralbracketisoperatingproperly.

Inspectingthe

Primary-DriveClutch

ServiceInterval:Beforeeachuseordaily

Clutchoperationshouldbemonitoreddailyforproper

shifting.Ifshiftingisstickyorsluggish,ortheclutch

doesnotreturncompletelytoneutralwhenidling,the

clutchrequiresasimplecleaning.

Note:Focusdebrisremovalinandaroundmoving

parts.

1.Engagetheparkingbrake,shutofftheengine,

andremovethekeyfromthekeyswitch.

2.Raiseandlatchthecargobox.

3.Removedirtandmudbuildupontheclutch

withwateranddrytheclutchimmediatelywith

compressedairtoremoveexcesswaterand

debris.

Note:Remainingdebrismayberemovedusing

afast-drying-contactcleaner.

45

Loading...

Loading...