ChangingtheTransaxle

Fluid

ServiceInterval:Every800hours/Yearly(whichever

comesrst)

FluidType:SAE10W-30(APIserviceSJorhigher)

FluidCapacity:1.4L(1.5USqt)

1.Parkthemachineonalevelsurface,shutoffthe

engine,engagetheparkingbrake,andremove

thekeyfromthekeyswitch.

2.Wipetheareaaroundthellanddrainplugs

cleanwitharag(Figure50).

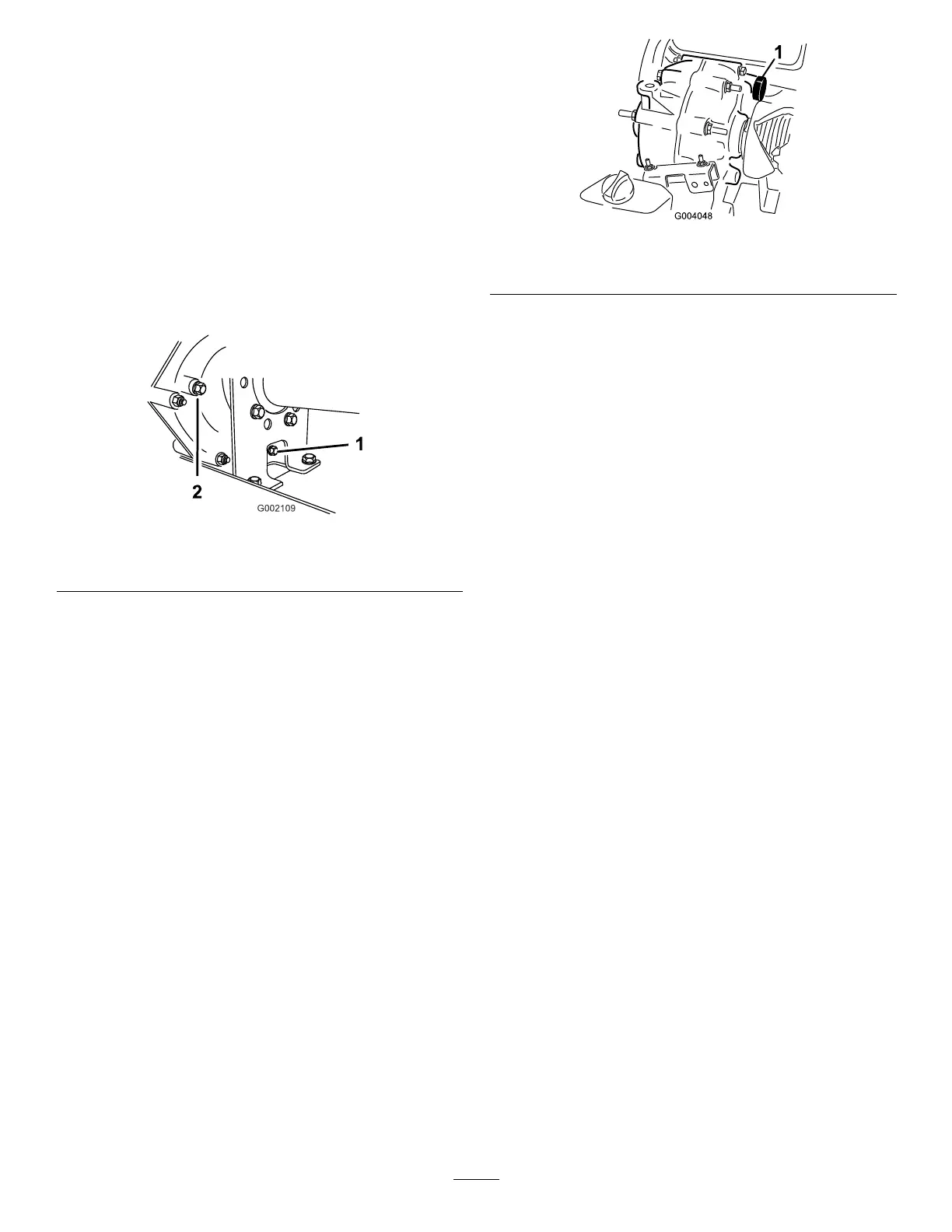

g002109

Figure50

1.Drainplug2.Fillplug

3.Alignadrainpanwithacapacityof2L(2.1qt)

ormoreunderthedrainplug.

4.Removethellplugbyrotatingit

counterclockwise(Figure50).

Note:Retainthellplugandgasketfor

installationinstep8.

5.Removethedrainplugbyrotatingit

counterclockwise(Figure50).

Note:Retainthedrainplugandgasketfor

installationinstep6.

Note:Allowtheoiltodrainfromthetransaxle

completely.

6.Installandtightenthedrainplugandgasketinto

thedrain-plugholeofthetransmission(Figure

50).

Note:Disposeoftheuseduidatacertied

recyclingcenter.

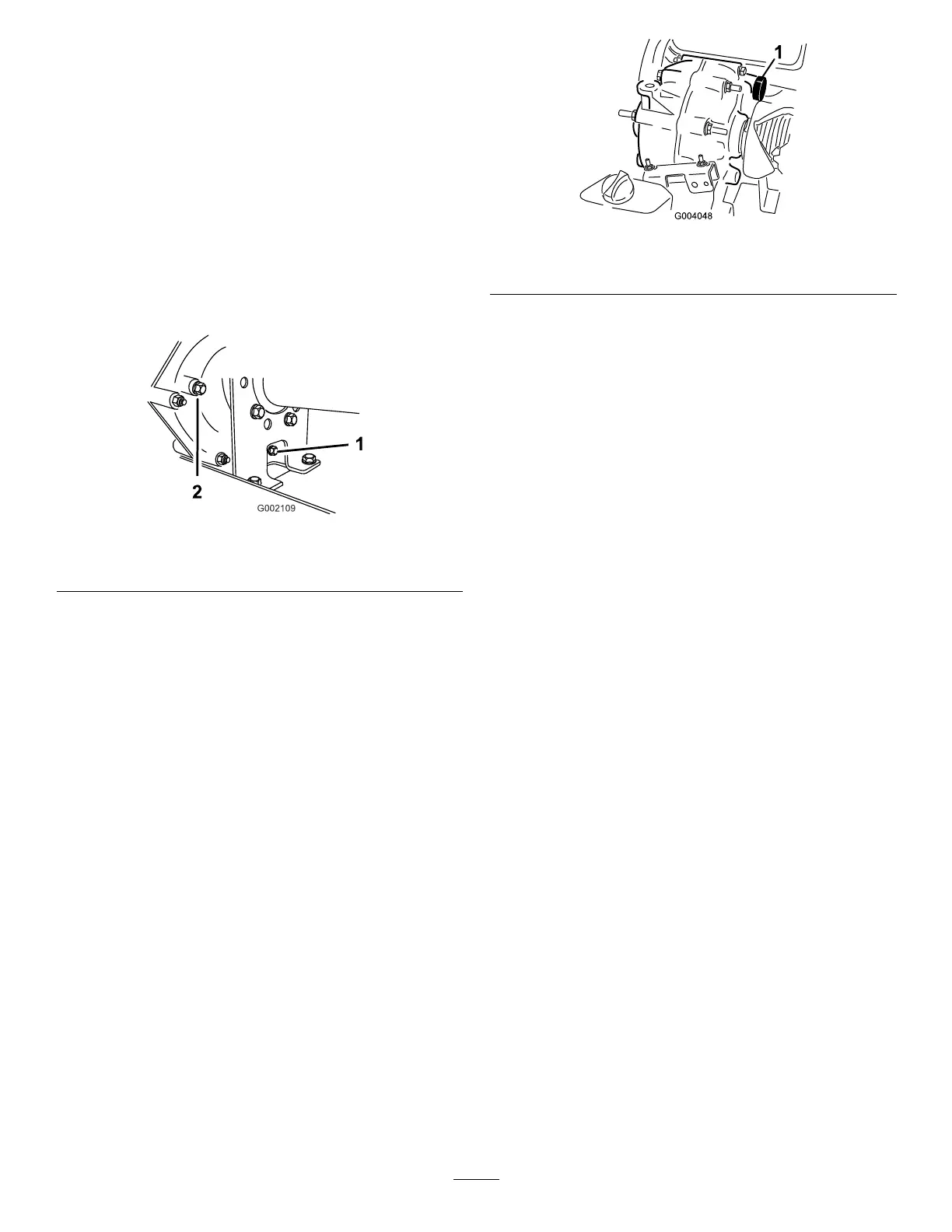

7.Fillthereservoir(Figure51)throughthell-plug

holewithapproximately1.4L(1.5USqt)of

thespecieduidoruntiltheuidlevelinthe

transmissionisevenwiththebottomofthe

threads.(Figure50).

g004048

Figure51

1.Fluidll

8.Installandtightenthellplugandgasketinto

thell-plugholeofthetransmission(Figure50).

9.Starttheengineandoperatethemachine.

10.Checktheuidlevelandaddmoreuidifthe

levelisbelowthethreadsofthell-plughole

(Figure50).

CheckingandAdjusting

Neutral

ServiceInterval:Every100hours

Whenperformingroutinemaintenanceand/orengine

diagnostics,youmustshiftintoNEUTRAL(Figure52).

ThemachinehasaNEUTRALpositionontheshift

lever,whichcontrolstheneutralinthetransaxle.The

followingstepsshouldbetakentomakesurethat

theneutralshiftleveroperatesthetransaxleneutral

correctly:

1.SettheshiftleverintotheNEUTRALposition.

2.EnsurethattheneutralbracketisintheNEUTRAL

position(leveltothecablemountingbracket

locatedbelowtheshiftbracket)byturningthe

drivenclutch(Figure52).

Note:Themachineshouldnotrollbackand

forth.Ifitdoes,manuallymovetheneutral

brackettotheNEUTRALposition.

44

Loading...

Loading...