BeltMaintenance

ServicingtheDriveBelt

Newbeltsmustbebrokeninbeforetheyshiftproperly.

Abeltbreaksinwithintherst2hoursofnormal

operation.

CheckingtheDriveBelt

ServiceInterval:Aftertherst8hours

Every200hours

Note:Iftheunitcontinuestomovewhentheengine

isatlowidle,theclutchesmaybedirtyandrequire

washing.

1.Parkthemachineonalevelsurface,shutoffthe

engine,engagetheparkingbrake,andremove

thekeyfromthekeyswitch.

2.Raisethecargoboxandsecureitwiththeprop

rod;refertoRaisingtheCargoBox(page18).

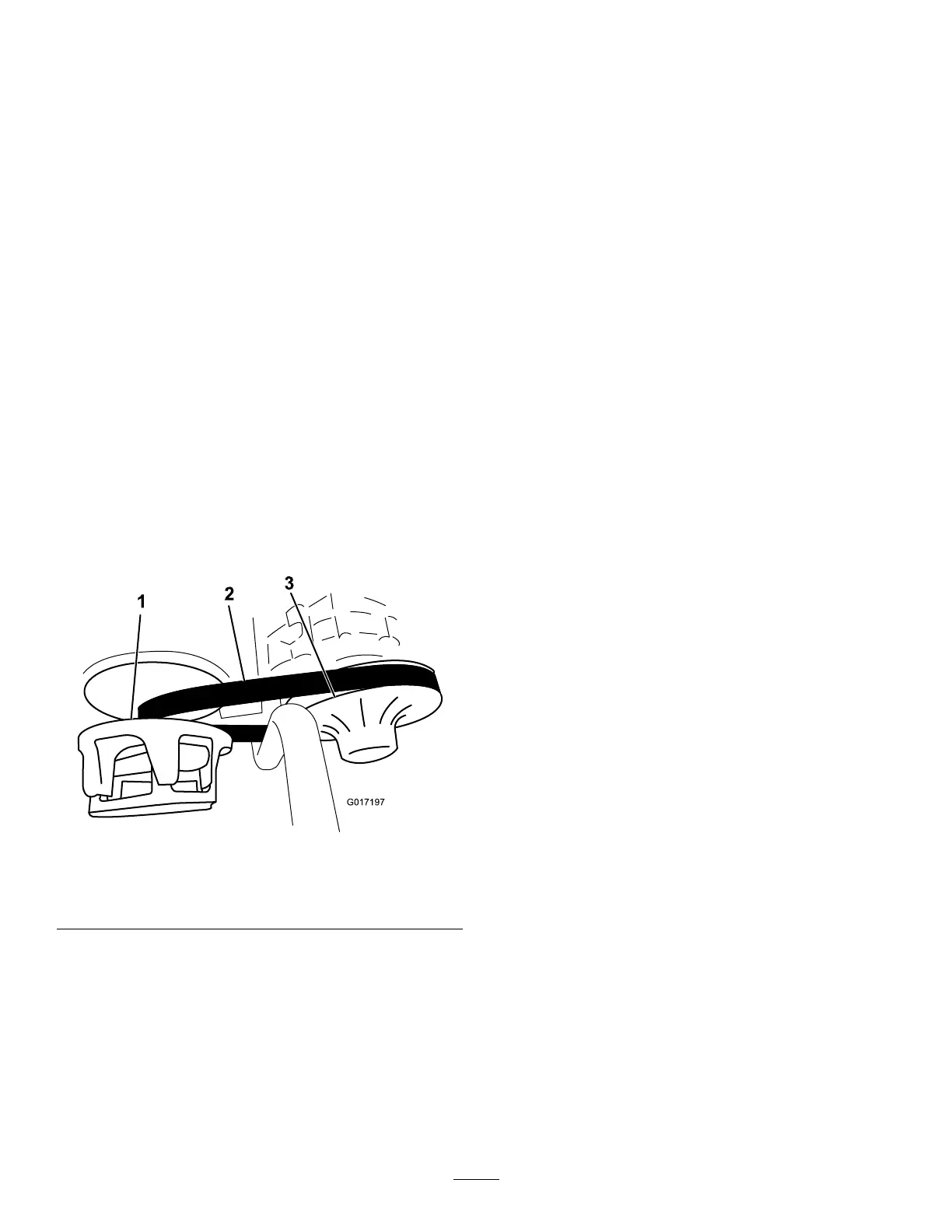

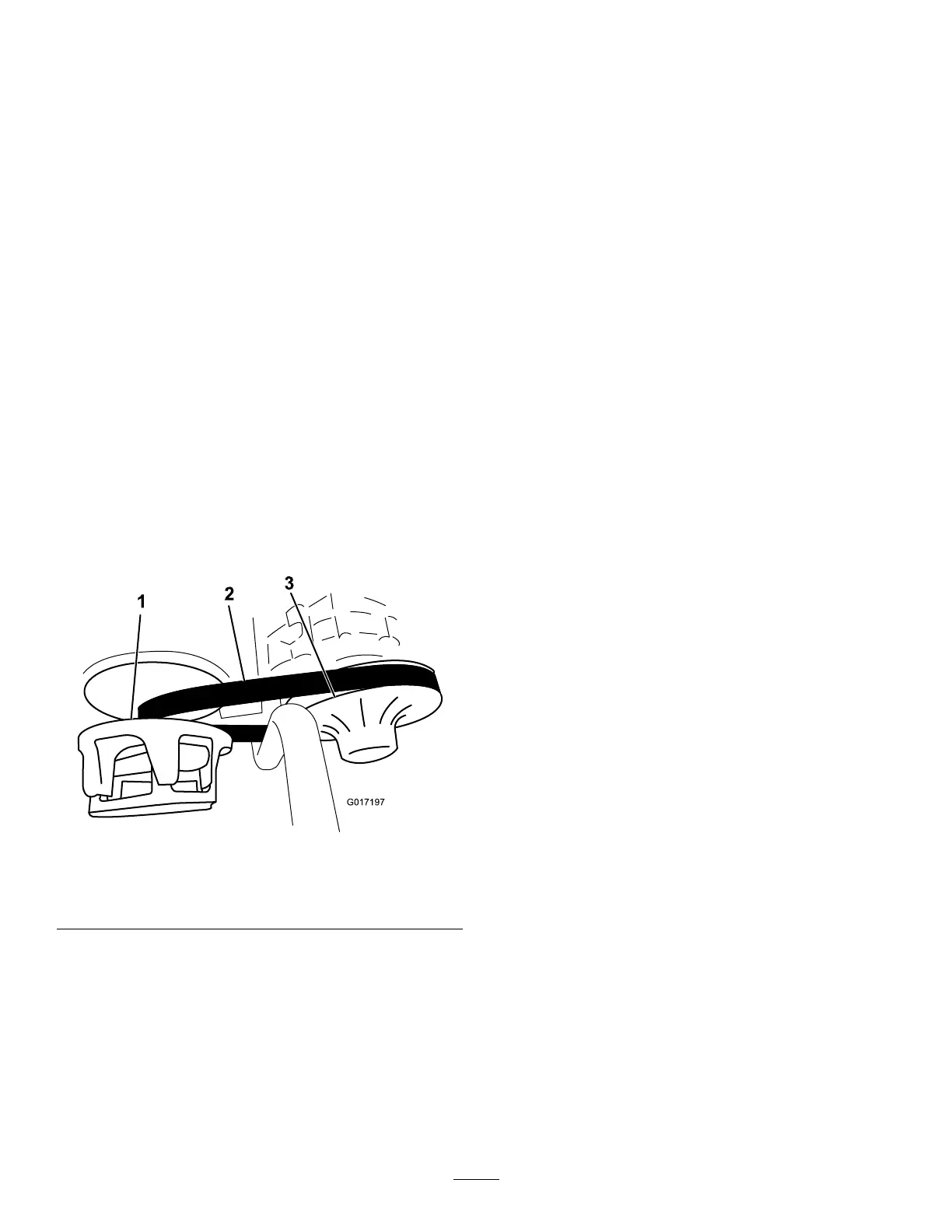

3.Rotateandinspectthebeltforexcessivewear

ordamage(Figure58).

Note:Replacethebeltifnecessary.

g017197

Figure58

1.Primaryclutch

3.Secondaryclutch

2.Drivebelt

4.Lowerthecargobox;refertoLoweringthe

CargoBox(page19).

ReplacingtheDriveBelt

1.Raisethecargobox;refertoRaisingtheCargo

Box(page18).

2.ShiftthetransmissiontotheNEUTRALposition,

shutofftheengine,engagetheparkingbrake,

andremovethekeyfromthekeyswitch..

3.Rotateandroutethebeltoverthesecondary

clutch(Figure58).

4.Removethebeltfromtheprimaryclutch(Figure

58).

Note:Discardtheoldbelt.

5.Alignthenewbeltovertheprimaryclutch

(Figure58).

6.Rotateandroutethebeltoverthesecondary

clutch(Figure58).

7.Lowerthecargobox;refertoLoweringthe

CargoBox(page19).

CheckingtheBelt-Pull

Bumper

Note:Checkthebelt-pullbumperonlywhen

troubleshootingvibration,performingarebuild,or

experiencinganengine-mountfailure.

Thebelt-pullbumper(Figure59)shouldmaintaina

gapof2.2mm(0.09inches).

Ifthebumperistooclosetotheenginebracket,the

beltwillcauseexcessivevibration.

Ifthebumperistoofarfromtheenginebracket,the

beltwillcauseharmfulenginestress.

Toadjustthegap,loosenthe3ange-headbolts

securingthebrackettotheframeandslidethebracket

theappropriatedistance.

Oncethegapiscorrect,tightenthe3ange-head

bolts.

49

Loading...

Loading...