CYLINDER HEAD

3. Measure:

• cylinder head warpage

Out of specification → Resurface the

cylinder head.

▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼ ▼

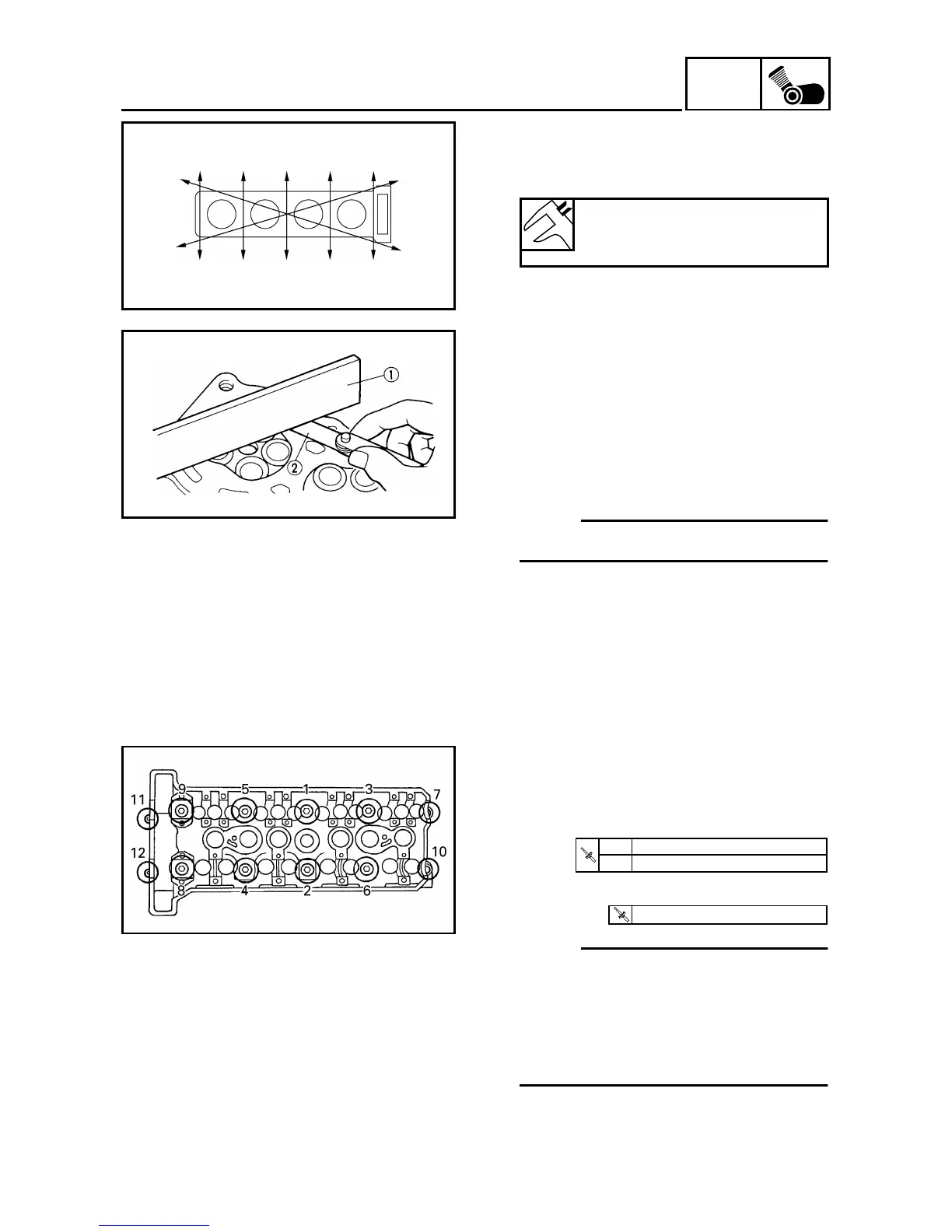

a. Place a straightedge 1 and a thick-

ness gauge 2 across the cylinder

head.

b. Measure the warpage.

c. If the limited is exceeded, resurface

the cylinder head as follows.

d. Place a 400 ~ 600 grit wet sandpaper

on the surface plate and resurface the

cylinder head using a figure-eight

sanding pattern.

NOTE:

To ensure an even surface, rotate the

cylinder head several times.

▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲ ▲

Maximum cylinder head

warpage

0.06 mm (0.0024 in)

EB402702

INSTALLING THE CYLINDER HEAD

1. Install:

• cylinder head

• cylinder head nut (1 ~ 10)

• cylinder head bolt (11, 12)

NOTE:

• Lubricate the cylinder head nuts with

engine oil.

• Tighten the cylinder head nuts and

bolts in two stages and in a crisscross

pattern.

• Tighten the nuts and bolts in numeri-

cal order (refer to the numbers in the

illustration).

T

R

.

.

1st. 20 Nm (2.0 m · kg, 14 ft · lb)

2nd. 50 Nm (5.0 m · kg, 36 ft · lb)

T

R

.

.

12 Nm (1.2 m · kg, 8.7 ft · lb)