Actual signals and parameters 209

2604 IR COMP

FREQ

Defines the frequency at which the IR compensation is 0 V.

See the figure for parameter 2603 IR COMP VOLT

Note: If parameter 2605 U/F RATIO is set to USER

DEFINED, this parameter is not active. The IR

compensation frequency is set by parameter 2610 USER

DEFINED U1.

80%

0…100% Value in percent of the motor frequency 1 = 1%

2605 U/F RATIO Selects the voltage to frequency (U/f) ratio below the field

weakening point.

SQUARE

D

LINEAR Linear ratio for constant torque applications. 1

SQUARED Squared ratio for centrifugal pump and fan applications.

With squared U/f ratio the noise level is lower for most

operating frequencies.

2

USER

DEFINED

Custom ratio defined by parameters 2610…2618. See

section Custom U/f ratio on page 133.

3

2606 SWITCHING

FREQ

Defines the switching frequency of the drive. Higher

switching frequency results in lower acoustic noise. See

also parameter 2607 SWITCH FREQ CTRL and section

Switching frequency derating, I2N and ILD (= all currents)

on page 339.

In multimotor systems, do not change the switching

frequency from the default value.

4kHz

4 kHz 1 = 1 kHz

8 kHz

12 kHz

16 kHz

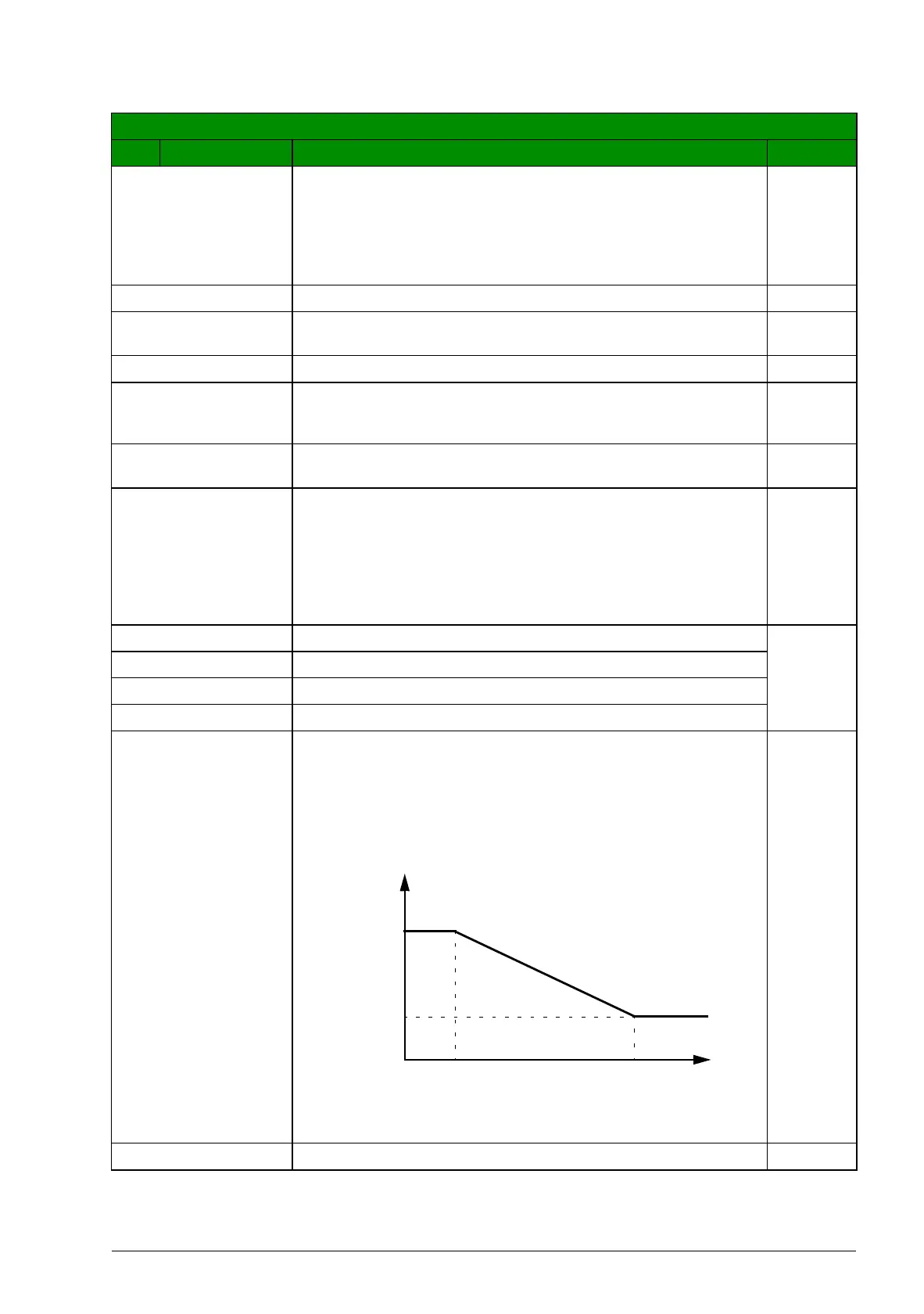

2607 SWITCH FREQ

CTRL

Activates the switching frequency control. When active, the

selection of parameter 2606 SWITCHING FREQ is limited

when the drive internal temperature increases. See the

figure below. This function allows the highest possible

switching frequency at a specific operation point.

Higher switching frequency results in lower acoustic noise,

but higher internal losses.

ON

ON Active 1

All parameters

No. Name/Value Description Def/FbEq

* Temperature depends on the drive output frequency.

16 kHz

4kHz

Drive

temperature

f

sw

limit

80…100 °C * 100…120 °C *

T

Loading...

Loading...