100 Maintenance

Descriptions of symbols

Recommended annual maintenance actions by the user.

Recommended maintenance intervals after start-up

Cleaning the interior of the cabinet

WARNING! Obey the instructions in chapter Safety instructions. If you

ignore them, injury or death, or damage to the equipment can occur.

WARNING! Use a vacuum cleaner with an antistatic hose and nozzle. Using a

normal vacuum cleaner creates static discharges which can damage circuit

boards.

1. Stop the drive and do the steps in section Precautions before electrical work on page

16 before you start the work.

2. When necessary, clean the interior of the cabinet with a soft brush and a vacuum

cleaner.

3. Check the air inlet and outlet meshes/filters of the cabinet. Clean when necessary.

For IP42 (UL Type 1 Filtered) drives:

see section Cleaning the air inlet (door) meshes

(IP42 / UL Type 1 Filtered) below.

For

IP54 (UL Type 12) drives: see section Replacing the air filters (IP54 / UL Type 12).

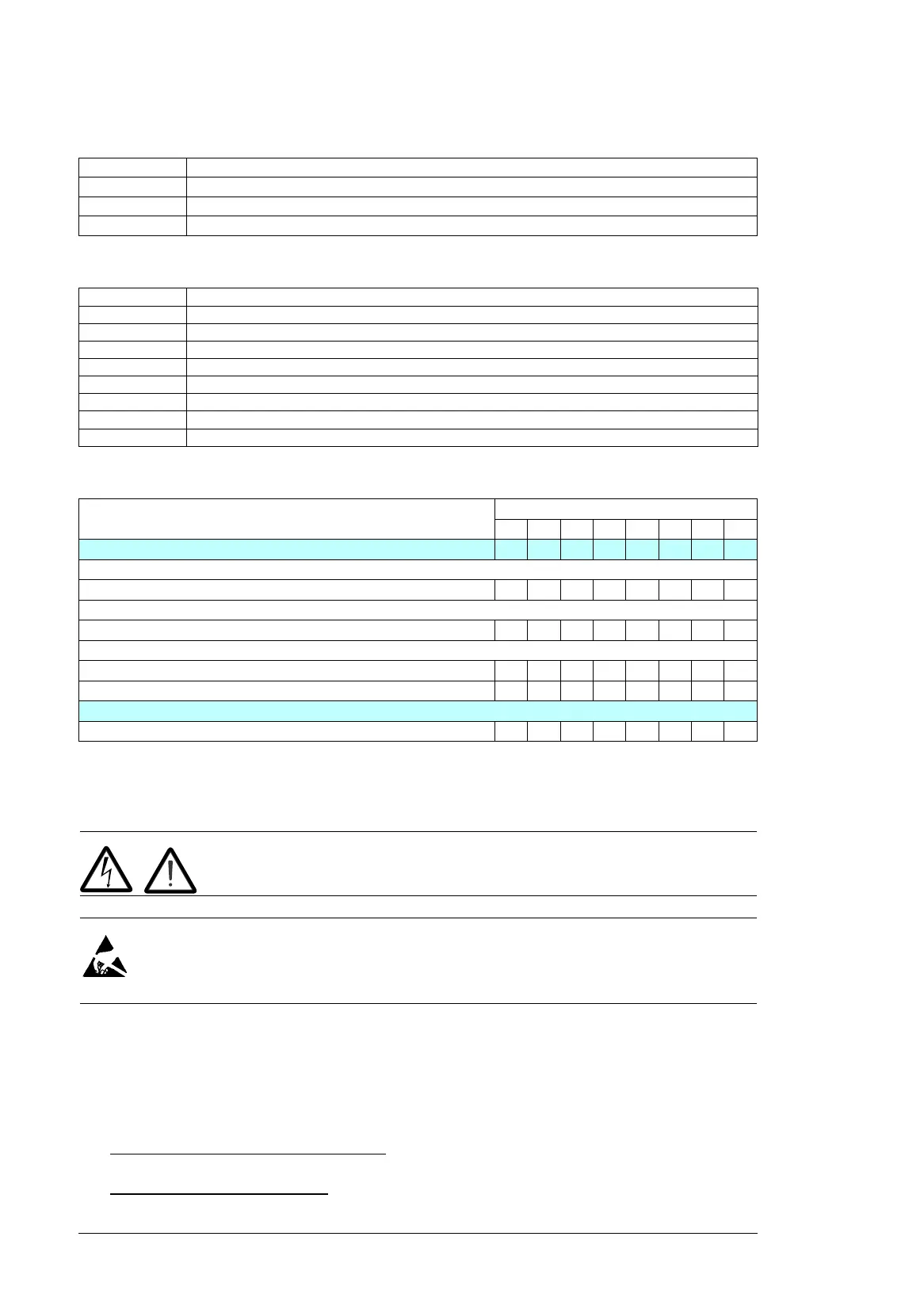

Action Description

I Visual inspection and maintenance action if needed

P Performance of on/off-site work (commissioning, tests, measurements or other work)

R Replacement of component

Action Target

I IP42 air inlet and outlet meshes on the cabinet doors

R IP54 air filters on the cabinet doors

P Quality of supply voltage

I Spare parts

P Capacitor reforming, spare modules and spare capacitors

I Tightness of terminals

I Dustiness, corrosion or temperature

I Heat sink cleaning

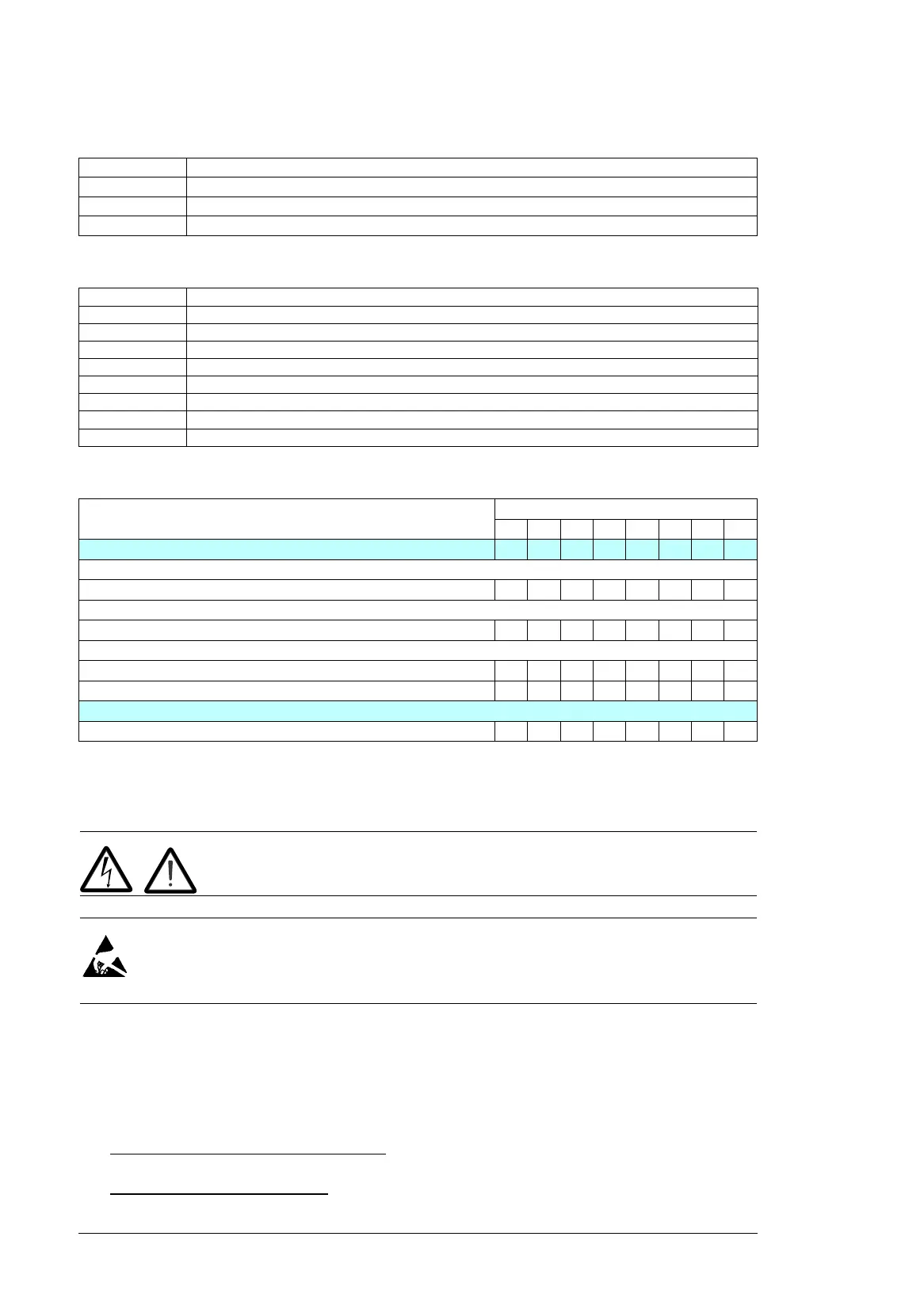

Component Years from start-up

3 6 9 1215182021

Cooling

Main cooling fan

Main cooling fan R R

Auxiliary cooling fan

Circuit board compartment cooling fans R R R

Cabinet cooling fan

Cabinet cooling fan IP54 R R R

Cabinet cooling fan, door R R R

Aging

Control panel battery R R

4FPS10000239703

Loading...

Loading...